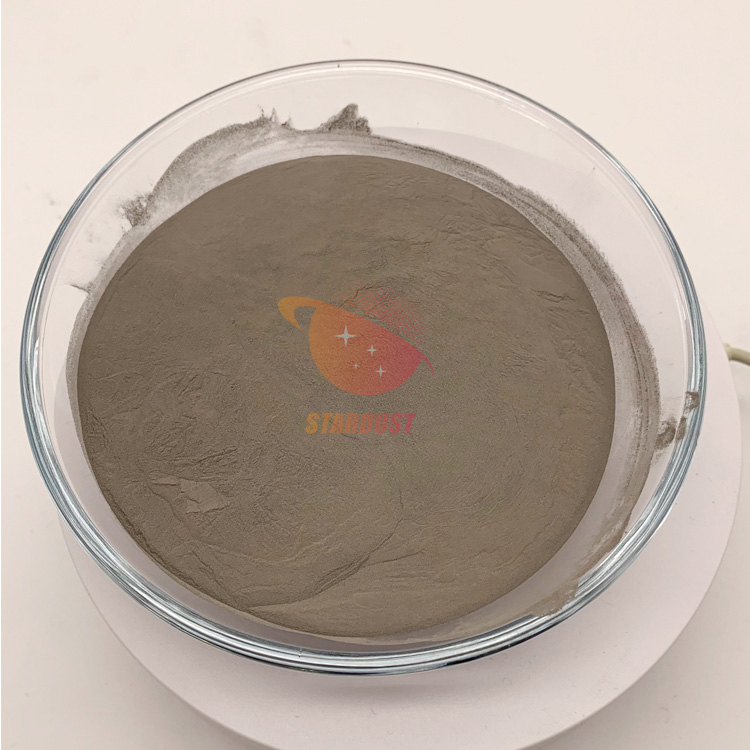

Spherical Refractory Ni-Ti Powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density.

Order quantity (minimum order quantity): determined by both parties

Payment method: determined by both parties

Product Origin: China

Shipping: determined by both parties

Order delivery time: 1-7 days

Order(MOQ) :

1 KgPayment :

T/T ; L/C at sightProduct Origin :

ChinaShipping Port :

Foshan / Guangzhou / ShenzhenLead Time :

1-7 daysNickel-titanium alloy powder has outstanding biocompatibility, high specific strength and excellent mechanical properties, and is widely used in biomedicine, aerospace, 3C electronics and other fields. Radio frequency plasma spherical titanium powder has the characteristics of high purity, high sphericity, no satellite balls, good fluidity, high packing density, no hollow particles, etc. It is suitable for 3D printing, hot isostatic pressing, injection molding and other processes.

Spherical TC4 powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

Spherical Refractory Ni-Ti Powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

Spherical TC4 powder is made by radio frequency plasma spheroidization atomization method, and has the characteristics of high purity, lack of oxygen, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flowability, high loose density and vibration density. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

Spherical TC4 powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

Spherical TC4 powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

Spherical Refractory Ni-Ti Powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

Spherical Refractory Ni-Ti Powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

Spherical Ti-75Ta alloy powder is an alloy powder of titanium (Ti) and tantalum (Ta), usually composed of 75% titanium and 25% tantalum. This alloy powder has a series of excellent properties and can be used in many fields. Order quantity (minimum order quantity): determined by both parties Payment method: determined by both parties Product Origin: China Shipping: determined by both parties Order delivery time: 1-7 days

Read More

IPv6 network supported

IPv6 network supported