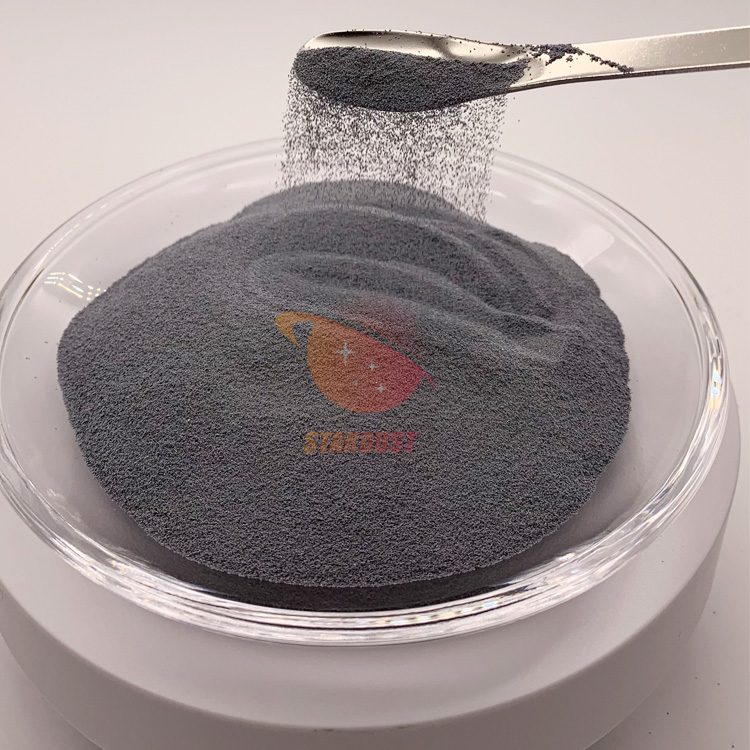

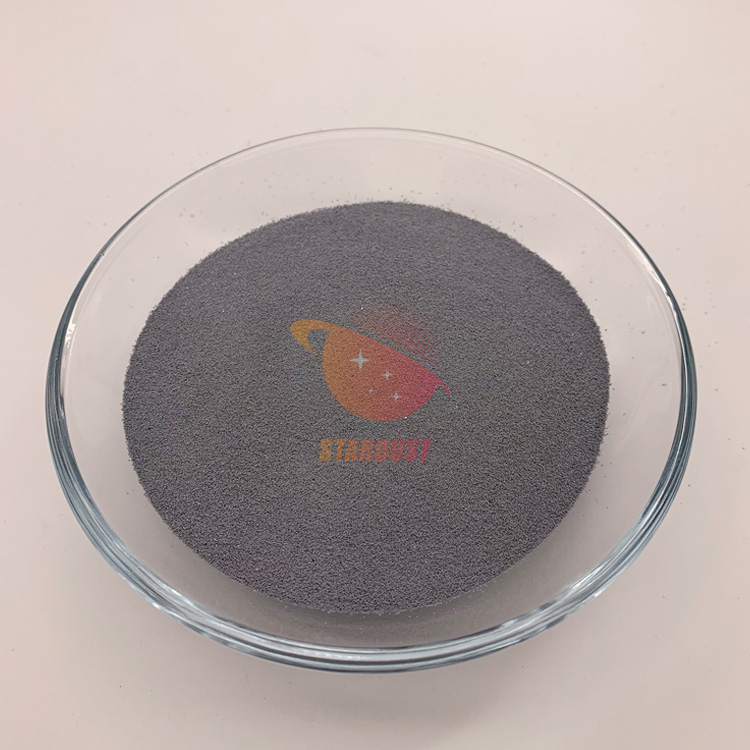

Spherical vanadium powder is prepared by RF plasma process, which has the characteristics of high purity, good sphericity, no satellite ball, very few hollow particles, etc. It is suitable for 3D printing, hot isostatic pressing, laser cladding and other processes.

Item No :

Spherical V PowderOrder(MOQ) :

1kgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Powder properties

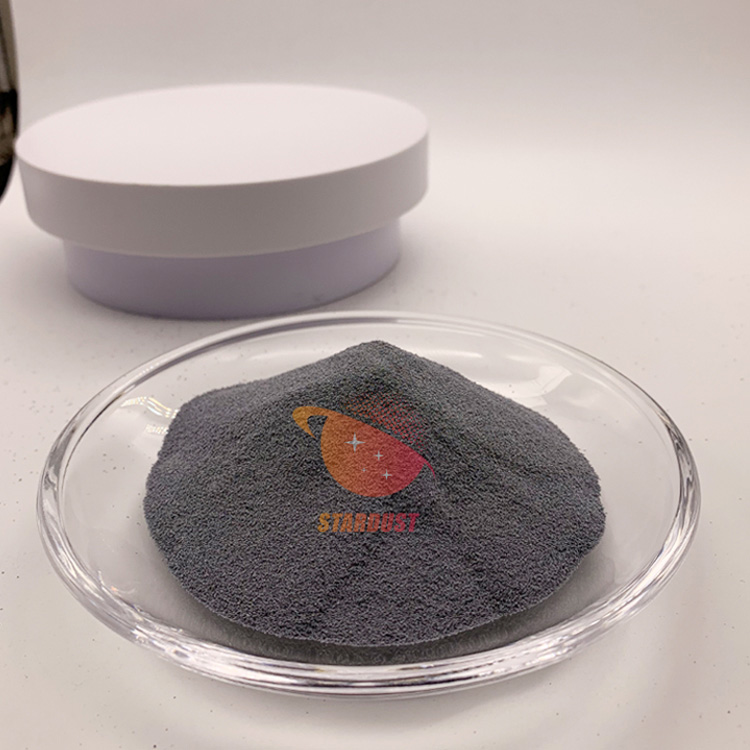

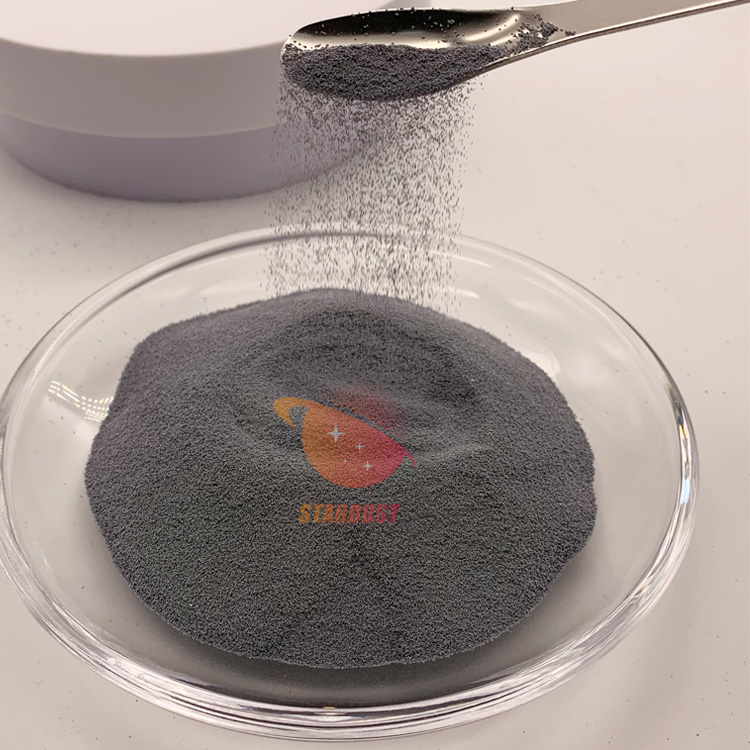

Morphology: Good sphericity, most particles present a relatively regular spherical shape, smooth surface, reduced friction and agglomeration between particles, and good dispersibility.

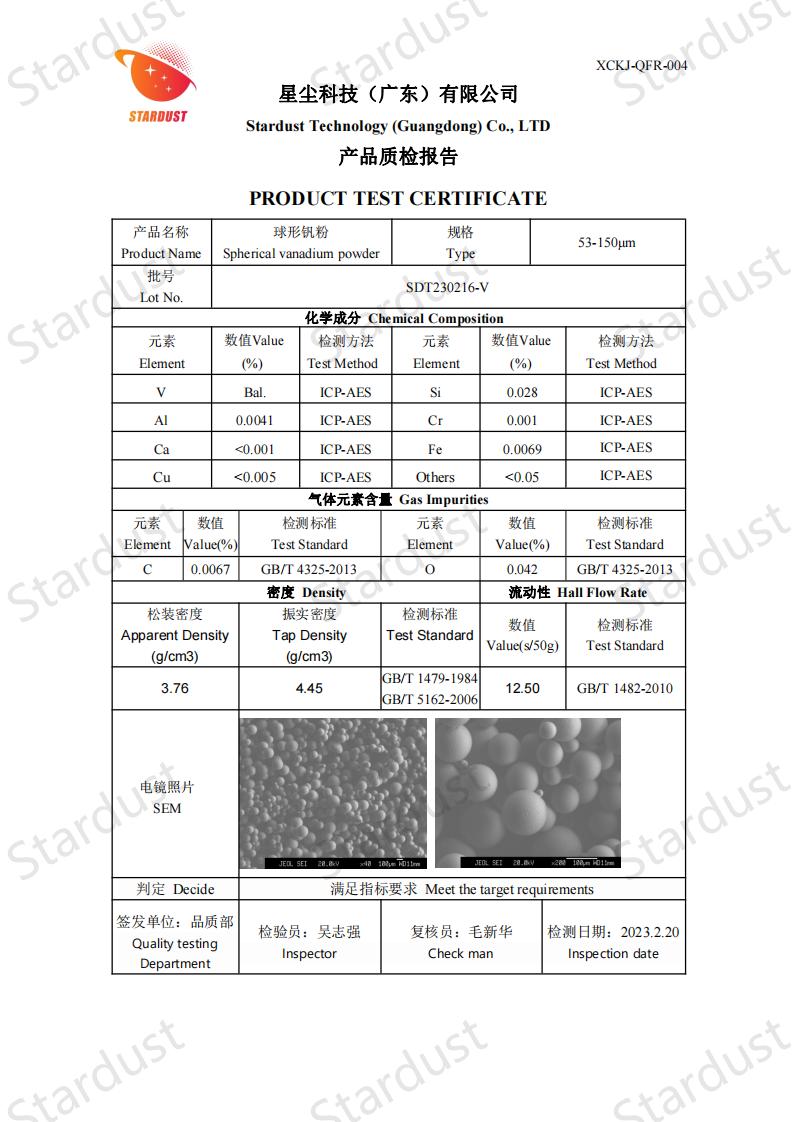

Particle size: The particle size distribution is relatively narrow, and can be controlled within a suitable particle size range through the process, commonly at the micron level, which can meet the particle size requirements of different applications.

Purity: The preparation process can effectively remove impurities, the vanadium powder has high purity, and the content of impurities such as oxygen, nitrogen, and carbon is low, ensuring the stability and consistency of product performance.

Density: The loose density and tap density are moderate, and the stacking performance is good, which is conducive to subsequent molding processing and provides a basis for improving the density of products.

Activity: It has certain chemical activity and can participate in reactions well in some chemical reactions and material preparation.

Application areas

Steel metallurgy: As a steel additive, it refines grains, improves the strength, toughness and fatigue resistance of steel, and is used to produce high-strength alloy steel, tool steel, etc., and is used in machinery manufacturing, construction and other industries.

Energy storage field: Participate in the preparation of vanadium flow batteries, use the multivalent characteristics of vanadium to achieve the storage and release of electrical energy, and apply it to large-scale energy storage power stations, renewable energy grid connection and other scenarios.

Alloy materials: Make vanadium-based alloys, such as vanadium aluminum alloys, etc., for the manufacture of high-temperature alloy parts in the aerospace field to improve the high temperature resistance and strength of the parts.

Catalyst: Used as a catalyst in chemical production to promote certain chemical reactions, such as playing a role in the production of sulfuric acid.

Preparation process

RF plasma spheroidization

Spherical vanadium powder is prepared by RF plasma process, which has the characteristics of high purity, good sphericity, no satellite ball, very few hollow particles, etc. It is suitable for 3D printing, hot isostatic pressing, laser cladding and other processes.

Read More

Spherical vanadium powder is prepared by RF plasma process, which has the characteristics of high purity, good sphericity, no satellite ball, very few hollow particles, etc. It is suitable for 3D printing, hot isostatic pressing, laser cladding and other processes.

Read More

Spherical vanadium powder is prepared by RF plasma process, which has the characteristics of high purity, good sphericity, no satellite ball, very few hollow particles, etc. It is suitable for 3D printing, hot isostatic pressing, laser cladding and other processes.

Read More

Spherical vanadium powder is prepared by RF plasma process, which has the characteristics of high purity, good sphericity, no satellite ball, very few hollow particles, etc. It is suitable for 3D printing, hot isostatic pressing, laser cladding and other processes.

Read More

Spherical vanadium powder is prepared by RF plasma process, which has the characteristics of high purity, good sphericity, no satellite ball, very few hollow particles, etc. It is suitable for 3D printing, hot isostatic pressing, laser cladding and other processes.

Read More

IPv6 network supported

IPv6 network supported