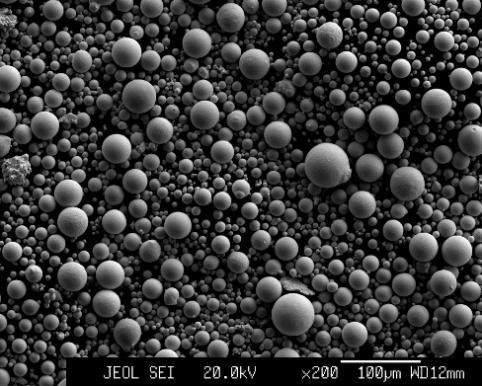

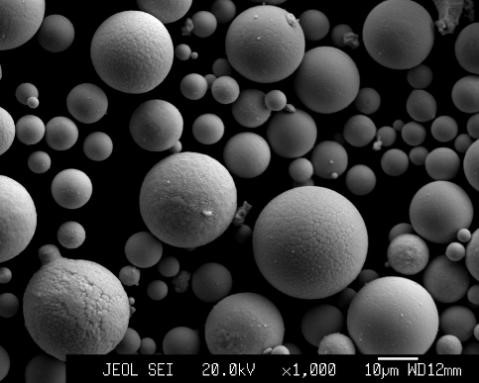

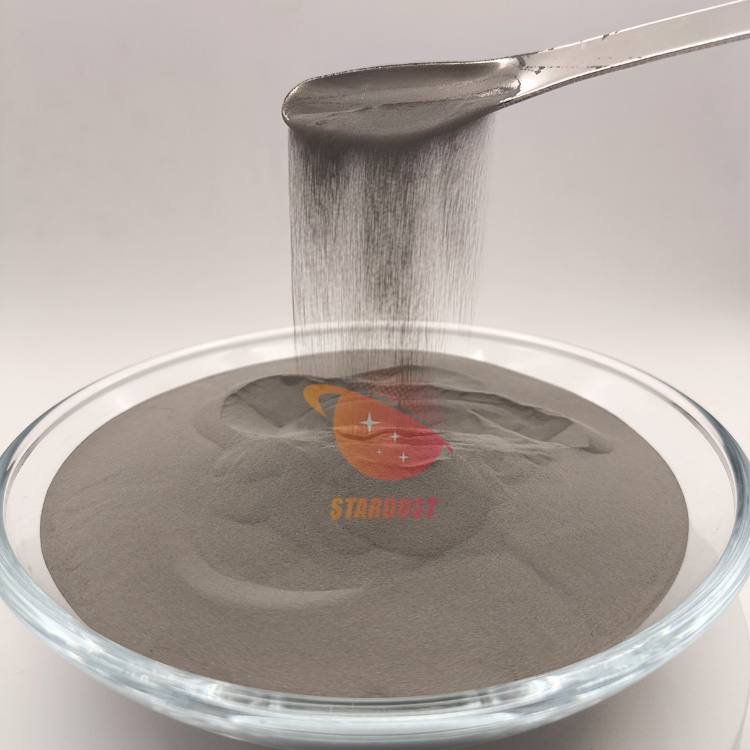

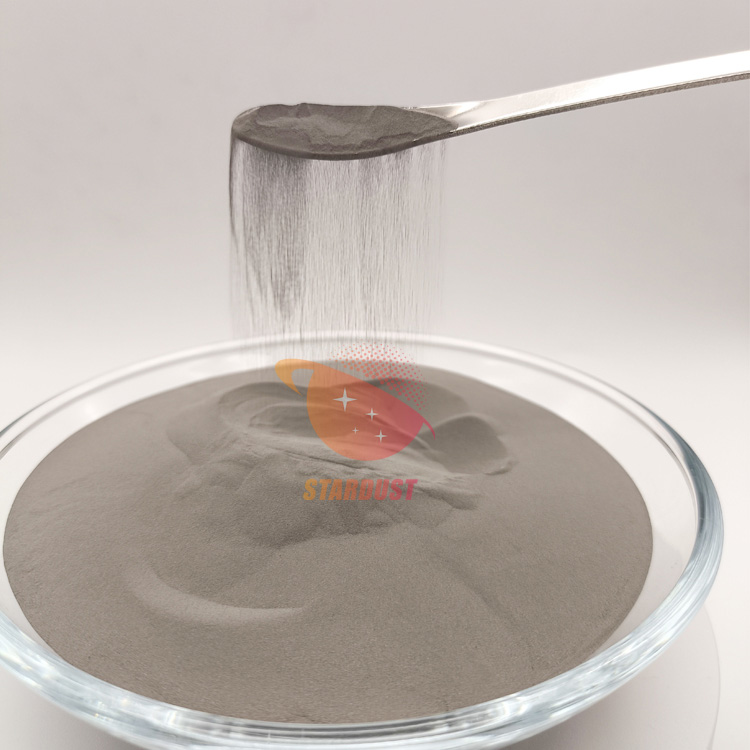

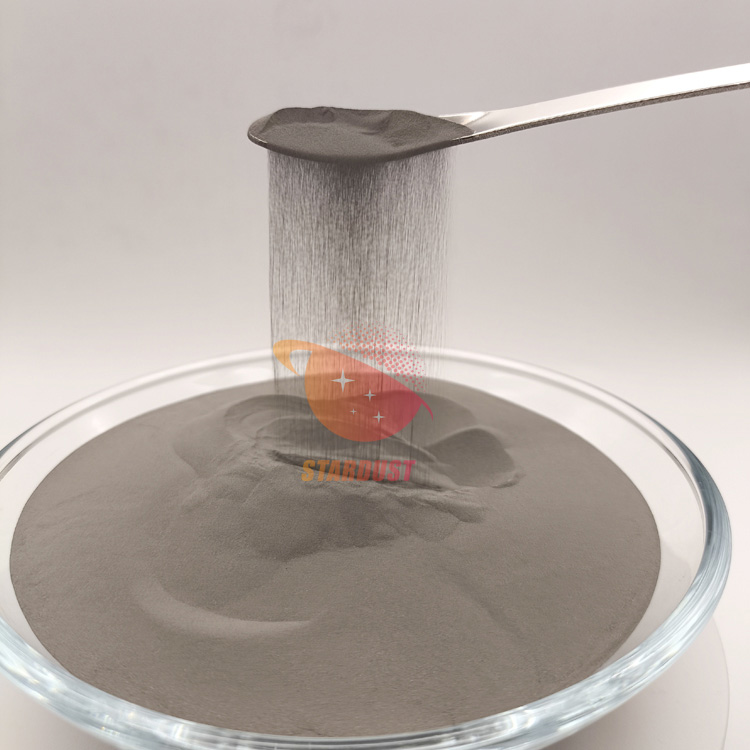

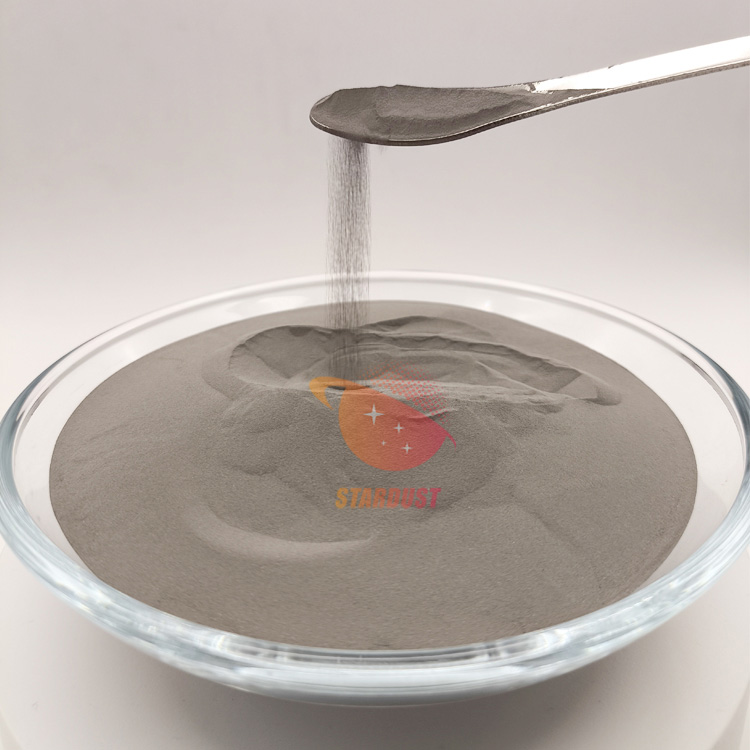

Spherical W-Mo-Ta-Nb powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density.

Order(MOQ) :

1KgPayment :

T/T; L/C at sightProduct Origin :

ChinaShipping Port :

Foshan / Guangzhou / ShenzhenLead Time :

1-7 daysStardust company provide spherical W-Mo-Ta-Nb alloy powder have high strength, high hardness, good high temperature performances, excellent wear and corrosion resistance. It's urgent demanded in the defense industry, aerospace, nuclear industry and other high-end fields. Radio-frequency plasma spheroidized refractory high entropy alloy powder have high purity, high sphericity , no satellite spheres, excellent flow properties, no hollow particle etc charateristics. Suitable for 3D printing, hot isostatic pressing, ejection molding, laser cladding and other processes.

We can not only provide relatively mature research on pure W-Mo-Ta-Nb alloy spherical powder but also provide 3D printing services, metal spheroidization services, 3D printing machines and devices .

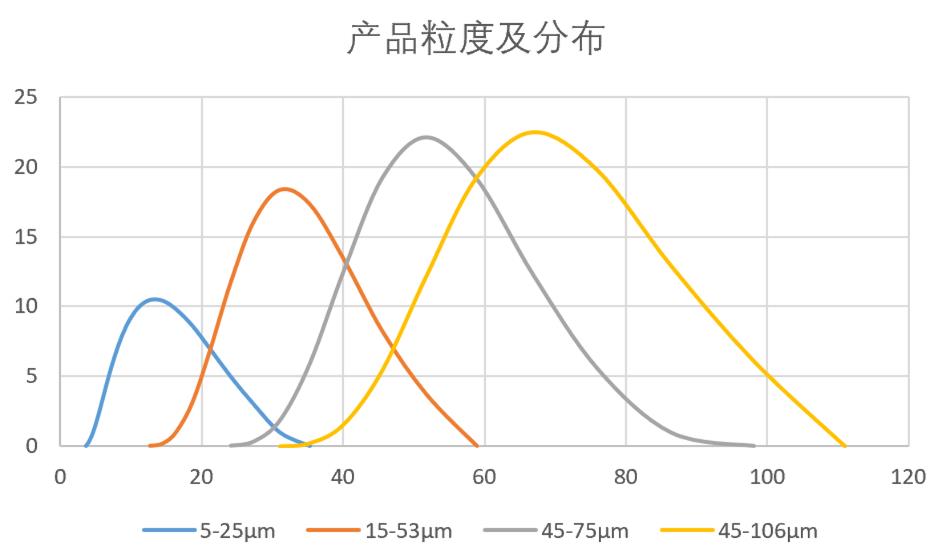

5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm.

(Various granularities can be customized according to customer requirements)

High purity, low oxygen (≤200ppm), high sphericity (≥98%), smooth surface, no satellite spheres, uniform particle size distribution, and excellent flow properties (≤10s/50g), And high bulk density (≥7.5g/cm3) and tap density (≥8g/cm3).

Vacuum packaging, 1kg/bag, 2kg/bag; iron drum lined with plastic bag 25 kg/drum; special packaging is available according to user requirements.

| Chemical Composition | |||||

| Element | Value (%) | Test Method | Element | Value (%) | Test Method |

| W | 34.55 | ICP-AES | Mo | 17.0 | ICP-AES |

| Ta | 32.03 | ICP-AES | Nb | 16.41 | ICP-AES |

| V | -- | ICP-AES | others | ≤0.1 | ICP-AES |

| Gas Impurities | |||||

| Element | Value (%) | Test Standard | Element | Value (%) | Test Standard |

| O | 0.0569 | GB/T 5124.1-2008 | |||

| Density (g/cm3) | Hall Flow Rate (s/50g) | |||

| Apparent Density | Tap Density | Test Standard | Value | Test Standard |

| 8.19 | 8.48 | GB/T 1479-1984 GB/T 5162-2006 |

7.84 | GB/T 1482-2010 |

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

IPv6 network supported

IPv6 network supported