Molybdenum alloys possess unique physical properties and excellent high-temperature strength [1], making them widely used in the production of high-temperature structural materials across various industrial sectors such as metallurgy and aerospace. Common molybdenum alloys include TZC (titanium-zirconium-carbon) and TZM (titanium-zirconium-molybdenum). TZC exhibits favorable high-temperature strength and recrystallization temperature, while TZM demonstrates excellent high-temperature strength and room-temperature plasticity [2]. The primary elements titanium (Ti), zirconium (Zr), and carbon (C) in these alloys form Mo-Ti and Mo-Zr solid solutions along with dispersed TiC and ZrC particles within the molybdenum matrix. This enhances both solid solution and dispersion strengthening effects, making them suitable for manufacturing piercing plugs for high-temperature alloy tubing [3]. Compared to TZM, TZC contains higher levels of Ti, Zr, and C (1.2% Ti, 0.3% Zr, 0.1% C by mass), facilitating the formation of dispersed carbide phases like TiC and ZrC. These elements enhance the alloy's strength [4], though its plasticity is relatively poor.

Molybdenum alloy piercing tips are categorized into two main types: cast molybdenum alloy tips and powder metallurgy molybdenum alloy tips. Cast molybdenum alloy tips exhibit poor plasticity, short service life, long production cycles, and high costs [5]. To overcome the process, performance, and cost disadvantages of cast molybdenum alloy tips, China successfully developed powder metallurgy molybdenum alloy tips in 1975 [6]. The high-temperature performance of molybdenum alloy piercing tips can be enhanced through solution strengthening and secondary phase strengthening. During piercing, molybdenum alloy tips endure complex axial forces, compressive stresses, shear stresses, and surface friction forces. Simultaneously, under mechanical impact, the tip is highly susceptible to failure [7].

After sintering, molybdenum alloys exhibit high-density porosity [8-9], severely compromising mechanical properties. To mitigate this, processes like forging and rolling are required to optimize microstructure and mechanical performance. However, molybdenum alloys are prone to severe oxidation at elevated temperatures [10], limiting both manufacturing processes and application scope. With modern technological advancements, an increasing demand exists for high-grade nickel-chromium stainless steel tubes requiring molybdenum alloy piercing heads for hot piercing forming [11]. Consequently, there is an urgent need to develop high-performance molybdenum alloys for piercing heads.

Currently, China has developed a novel sintering technique—vacuum hot-press sintering—capable of reaching maximum temperatures of 2,200°C and pressures up to 60 MPa. This technology has begun application in powder sintering processes [12]. This method requires loading powders into graphite molds during sintering. Applying additional axial pressure when the temperature reaches the predetermined level effectively increases the density of the sintered body, which is crucial for enhancing the material's mechanical properties. Research indicates that during sintering, the addition of TiH₂/ZrH₂ to TZC alloys decomposes to release Ti and Zr elements, forming Mo(Ti) solid solutions and secondary phase particles such as TiC and ZrC. Post-sintering hot pressing altered the microstructure of the specimens, forming a Mo matrix, Mo recrystallization zone, impurity defect zone, and carbon source defect zone. Thus, vacuum hot pressing sintering offers a novel process route for fabricating high-performance molybdenum alloy piercing tips.

The authors added TiH₂ and ZrH₂ to molybdenum alloys, supplemented with rare earth oxides Y₂O₃ and CeO₂, and sintered the prepared alloys. Vacuum hot pressing at 1860 °C and 40 MPa reduced internal porosity, providing reference for optimizing the design and manufacturing process of molybdenum alloy piercing tips.

1 Experimental Materials and Methods

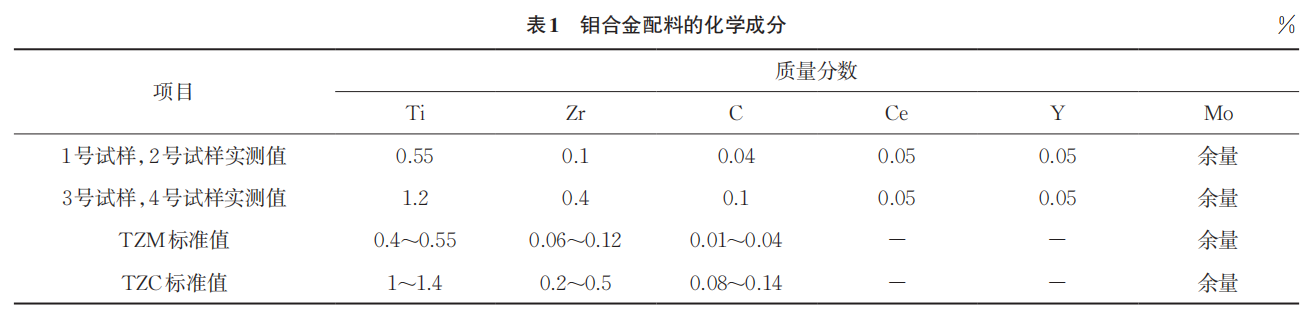

The molybdenum alloy was prepared using a solid-solid mixture method, with the chemical composition of the alloy ingredients shown in Table 1. The molybdenum powder used was synthesized from ammonium molybdate as the raw material, yielding MoO₃ through reaction, which was then reduced with hydrogen gas to produce high-purity molybdenum powder. The average particle size of the molybdenum powder was 1.5 μm, while the particle sizes of TiH₂ and ZrH₂ were both 1 μm, and the average particle size of the carbon powder was 50 μm. The mixed raw materials were placed in a three-dimensional mixer and blended for 12 hours to achieve uniform powder mixing. The mixed powder was then loaded into a mold sleeve and pressed into a blank with dimensions of 60 mm × 160 mm (diameter × height) using an isostatic press at 200 MPa. The molybdenum alloy was prepared via medium-frequency sintering, with the sintering process curve shown in Figure 1. The prepared molybdenum alloy specimens (designated as Specimens 1, 2, 3, and 4) underwent vacuum hot-pressing treatment in a vacuum hot-pressing furnace. Hot-pressing was performed at 1860 °C and 40 MPa with a 5% deformation rate.

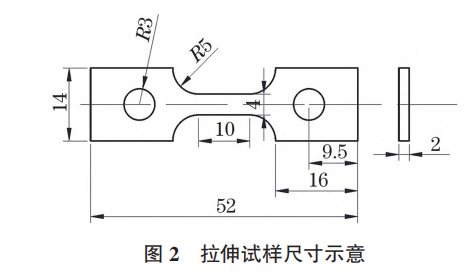

The original density of each specimen and the density change after sintering and hot-pressing were determined using the Archimedes displacement method. Specimens were cut using wire-cutting methods. Microstructures were observed using optical microscopy and scanning electron microscopy (SEM). Chemical compositions of secondary phases were analyzed using an energy dispersive spectrometer. Hardness tests were performed on polished specimens using a Vickers hardness tester, with values averaged. Room-temperature tensile tests were conducted on universal testing machines. Tensile specimen dimensions are shown in Figure 2.

2 Test Results

2.1 Density and Microstructure of the Alloy Before and After Sintering and Hot Pressing

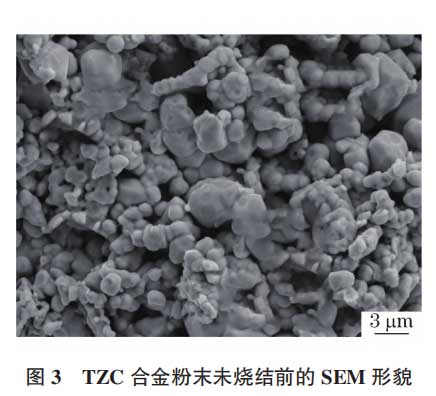

Figure 3 shows the SEM morphology of the unsintered TZC alloy powder. As seen in Figure 3, the alloy powder contains two distinct particle sizes, with particles approximately 1.5 μm in diameter constituting 70% of all particles. Energy dispersive spectroscopy (EDS) analysis of these particles revealed they were agglomerates formed by TiH₂, ZrH₂, carbon powder, and molybdenum powder under isostatic pressing. Some particles with diameters around 2.5 μm were primarily composed of molybdenum powder. Points in the image showed higher oxygen content, attributed to oxygen adsorption during sieving and pressing. Gaps existed between powder particles.

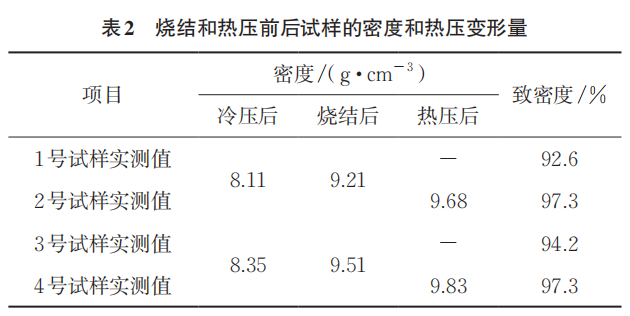

Densities of TZC and TZM blanks measured by Archimedes' principle were 8.11 g/cm³ and 8.35 g/cm³, respectively. After sintering, their densities increased to 9.21 g/cm³ and 9.51 g/cm³, representing density gains of 13.5% and 13.9%. After hot pressing with identical deformation, their densities reached 9.75 g/cm³ and 9.83 g/cm³, representing increases of 5.1% and 3.4% over the sintered state. The theoretical densities of the two alloy compositions were calculated as 9.95 g/cm³ and 10.1 g/cm³. The densities and hot-press deformation of specimens before and after sintering/hot pressing are summarized in Table 2. Although the sintered densities of the two alloys were 92.6% and 94.2%, respectively, both achieved a density of 97.3% after hot pressing.

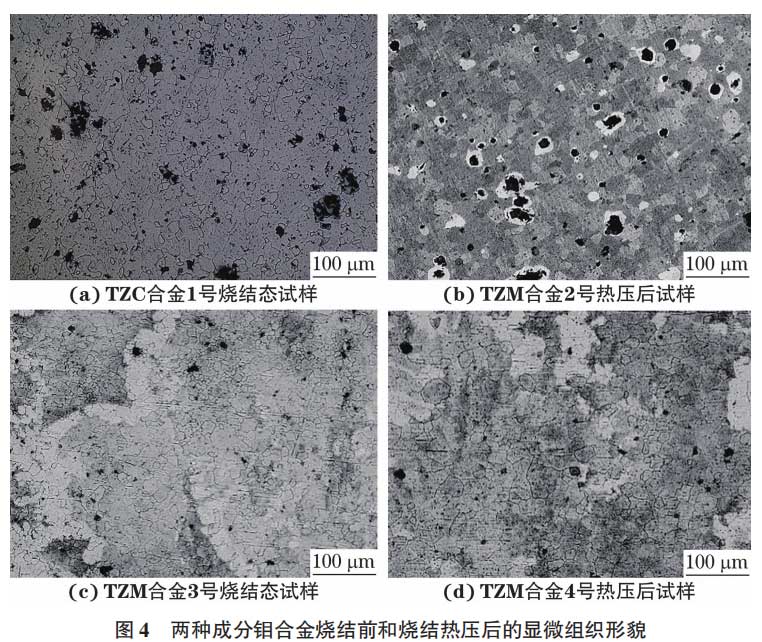

The microstructural morphology of the two molybdenum alloys before sintering (Specimens 1 and 3) and after sintering and hot pressing (Specimens 2 and 4) is shown in Figure 4. As shown in Figure 4: The grains in both TZC and TZM alloy specimens exhibited mixed crystalline structures after sintering. Following hot pressing, the grains grew in size and became more uniform, with straight and well-defined grain boundaries exhibiting an equiaxed morphology. Grain size analysis revealed that the average grain diameter of the sintered TZC alloy was approximately 23 μm, while the grain size of the alloy subjected to both sintering and hot pressing was about 35 μm, indicating significant grain growth during hot pressing. For TZM alloy specimens sintered only, the average grain diameter was approximately 28 μm, increasing to about 40 μm after hot pressing. Due to the fewer alloying elements in TZM and its weaker ability to inhibit grain boundary migration, its grain diameters were slightly larger than those of the TZC alloy. Additionally, Figures 4(a) and 4(b) reveal that TZC specimens contain a significant proportion of defects, including irregularly shaped inclusions and pores of varying sizes, accounting for approximately 10% of the structure. After hot pressing, the proportion of inclusions and pores in the alloy decreased markedly to about 3%, with their shapes transforming from irregular to regular spherical forms, exhibiting distinct reaction diffusion characteristics. Since the TZM alloy contains significantly lower levels of elements such as C, Ti, and Zr compared to the TZC alloy, the defect proportion in the TZM specimens is markedly reduced.

2.2 Mechanical Properties and Piercing Verification

The room-temperature tensile properties and hardness test results of the two-component molybdenum alloy after sintering and hot pressing are shown in Table 3. Table 3 indicates: For the TZC molybdenum alloy, the yield strength of Specimen 1 after sintering ranged from 266 to 285 MPa, with tensile strength between 315 and 338 MPa. However, its elongation after fracture was low, approximately 0.5%, and microhardness was 210 HV5. The average yield strength of Specimen 2 after hot pressing increased by approximately 13% compared to Specimen 1, and the elongation after fracture also improved significantly. Microhardness increased by 20%. For TZM alloy, the sintered Specimen 3 exhibited a yield strength of 237–258 MPa, tensile strength of 366–382 MPa, elongation after fracture of 1%, and microhardness of 195 HV5. Although the yield strength of TZM alloy specimens was lower than that of TZC alloy specimens, the tensile strength was significantly higher, demonstrating the excellent low yield-to-tensile strength ratio characteristic of TZM alloy. After hot pressing, the average yield strength of TZM alloy Specimen 4 increased by approximately 20% compared to Specimen 3, the elongation after fracture increased by about 45%, and the microhardness increased by 29%.

After vacuum hot pressing, both TZC and TZM alloy specimens exhibited significant improvements in mechanical properties and density. To evaluate the impact of hot pressing on the service performance of these molybdenum alloys, finished punches were fabricated from both alloy specimens and subjected to tube piercing tests at 1160°C. Results are shown in Table 3. The piercing material was 022Cr17Ni12Mo2 steel. The sintered-state piercing tools of both alloys could only pierce 150 tubes, while the hot-pressed Specimen No. 2 (TZC) pierced 271 tubes and Specimen No. 4 (TZM) pierced 261 tubes before showing essentially intact conditions. Surface wear and oxidation were observed on the piercing heads, but no cracks were detected, and the piercing holes remained intact.

2.3 SEM Morphology of Fracture Surfaces

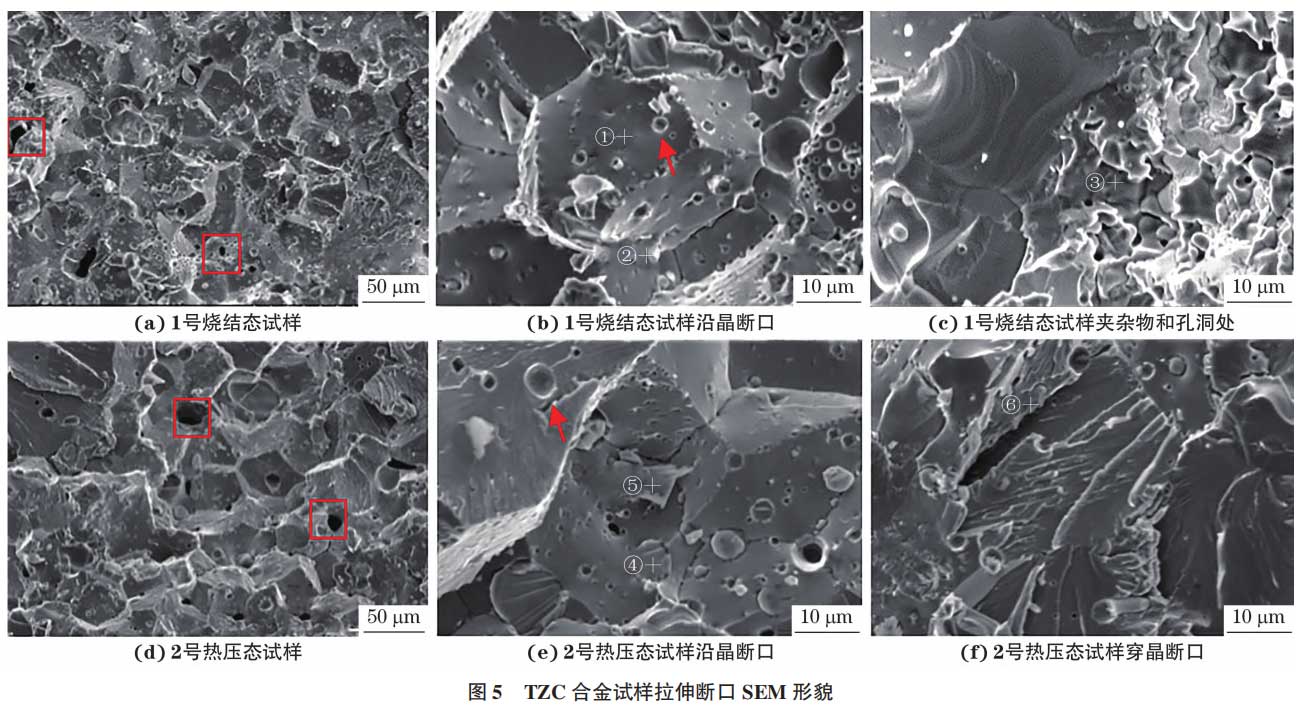

Two primary strengthening mechanisms exist in molybdenum alloys: solution strengthening and secondary phase strengthening. Both are achieved through alloying with Ti, Zr, and C elements during preparation. The SEM morphology of the TZC alloy specimen fracture surface is shown in Figure 5. As depicted in Figure 5: The fracture surface of Specimen 1 in the sintered state primarily exhibits typical intergranular brittle fracture characteristics. Clear grain boundaries are observable across the fracture surface, with pores present on the grain boundary surfaces [see Figure 5(a)] or pits formed by the detachment of secondary phase particles [see Figure 5(b)]. Additionally, large voids and inclusions are visible [see Fig. 5(c)], resulting from reaction diffusion of dopant elements during sintering. The fracture surfaces of the hot-pressed Specimen 2 and Specimen 1 exhibit essentially identical characteristics. Beyond intergranular fracture features [see Fig. 5(d), 5(e)], partial transgranular fracture characteristics are also present [see Fig. 5(f)]. River-like patterns were present in certain areas of the intergranular fracture surface, with each branch corresponding to parallel cleavage steps of varying heights. Clear grain boundaries were observable on the fracture surfaces of both types of specimens, all containing numerous second-phase particles.

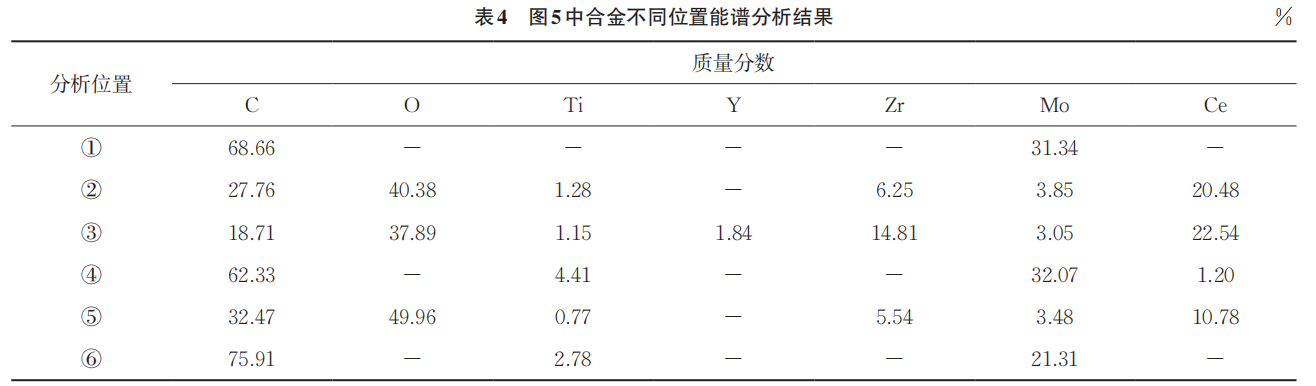

Energy dispersive spectroscopy (EDS) analysis of precipitates on the fracture surface yielded results shown in Table 4. The fine precipitates (analysis positions ①) on the sintered fracture surface of TZC Alloy 1 specimen primarily consist of Mo₂C and MoC. At grain boundaries and defects, these precipitates exhibit spherical or near-spherical (analysis positions ②, ③), composed mainly of O, C, Ti, Zr, Mo, Ce, and trace Y. The primary phases were CeO₂, TiC, ZrC, Mo₂C, with possible TiO₂ and ZrO₂ presence. The main elements at grain boundaries in the fracture surface of TZC Alloy 2 were similar to those in Alloy 1, and the second phases were also largely comparable. Additionally, analysis results from position ⑥ indicate that TiC and Mo₂C particles precipitate in the alloy after hot pressing.

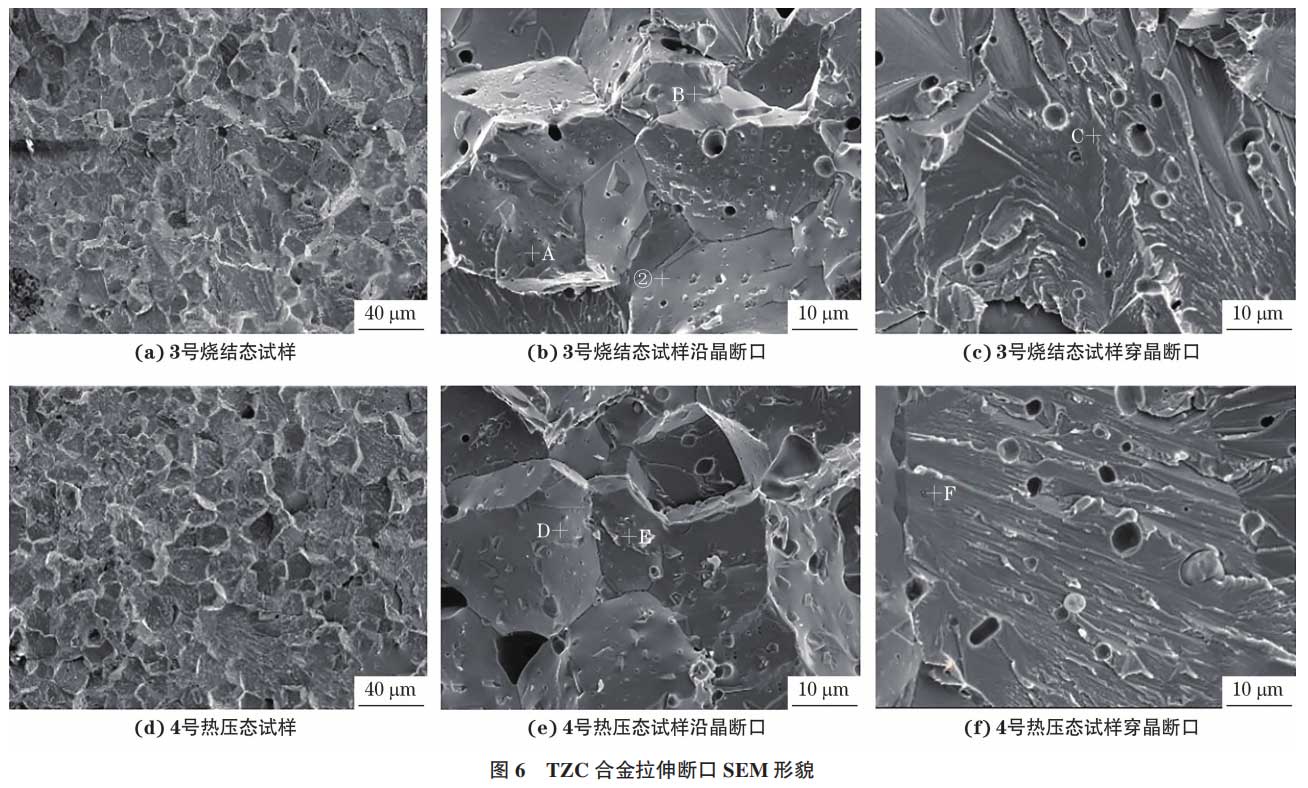

The SEM morphology of the TZC alloy tensile fracture surface is shown in Figure 6. As seen in Figure 6, both sintered and hot-pressed specimens exhibit typical brittle fracture characteristics. The fracture surface displays a rock-candy-like appearance, with Mo grains being nearly equiaxed and distinct grain boundaries clearly visible, indicating intergranular or transgranular fracture behavior.

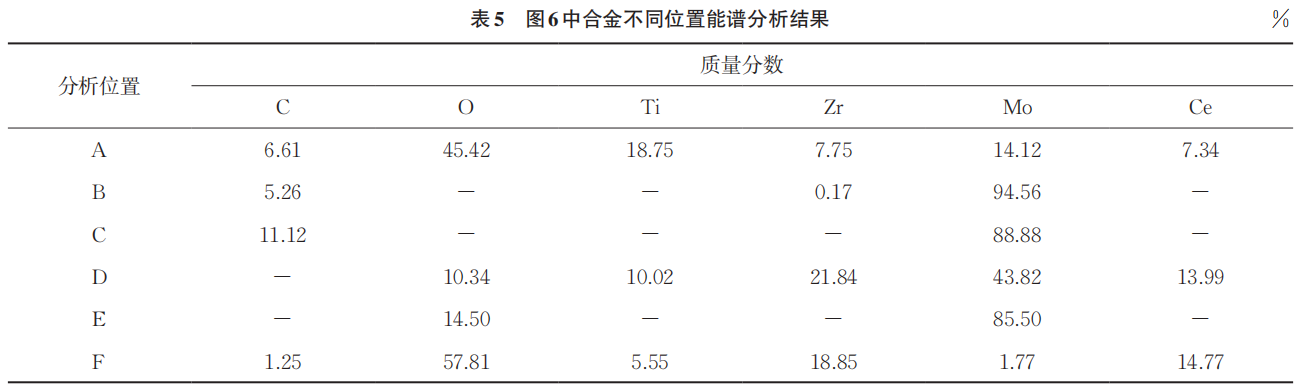

Energy dispersive spectroscopy (EDS) analysis of the secondary phase particles yielded the results shown in Table 5.

As shown in Table 5: The particles at grain boundaries on the intergranular fracture surface of sintered specimen No. 3 primarily consist of two types. One type comprises composite oxide particles dominated by C, O, Ti, Zr, Mo, and Ce elements (analysis location A), while the other type comprises carbide particles dominated by C, Zr, and Mo elements (analysis location B). In contrast, particles on the intergranular fracture surface contained only C and Mo (analysis location C), likely corresponding to Mo₂C. For the hot-pressed Specimen 4, the second-phase particles on both the intergranular and intergranular fracture surfaces exhibited essentially identical elemental compositions, containing O, Ti, Zr, Mo, Ce, and C. These primarily comprised composite oxides containing Mo, Ti, Zr, and CeO₂, along with minor carbides.

In summary, the precipitated phases on the fracture surfaces of both molybdenum alloys are essentially identical. Due to the tendency for elements such as C and O to enrich at grain boundaries, the alloys exhibit extensive distribution of composite oxides and carbides, leading to predominantly intergranular fracture. Although hot pressing significantly improved the alloy's density and enhanced the mechanical properties of the specimens, it did not alter the fundamental brittle fracture nature of the material.

3 Conclusions

(1) Hot pressing increased the density of the alloys. The densities of TZC and TZM alloys after sintering were 9.21 g/cm³ and 9.51 g/cm³, respectively. After hot pressing, their densities increased to 9.75 g/cm³ and 9.83 g/cm³, representing increases of 5.1% and 3.4% compared to the sintered state, achieving a density of 97.3%.

(2) Hot pressing promotes grain growth. Both TZC and TZM alloys exhibited mixed grain structures after sintering. Following hot pressing, the average grain diameters increased from 23 μm to 35 μm and from 28 μm to 40 μm, respectively. The proportions of inclusions and voids in the hot-pressed alloys were significantly reduced.

(3) Hot pressing enhances the mechanical properties of the alloys. For TZC molybdenum alloy, the average yield strength increased by approximately 13% compared to the sintered state, the elongation after fracture increased by about 210%, and the microhardness improved by 20%. For TZM alloy, the average yield strength of hot-pressed TZC molybdenum alloy increased by approximately 20% compared to the sintered state, the elongation after fracture increased by about 45%, and the microhardness increased by 29%.

(4) The precipitation phases in both alloys were essentially consistent, and the tensile fracture surfaces of the alloys exhibited brittle fracture characteristics, primarily intergranular fracture. Hot pressing extended the die life, with both TZC and TZM alloys showing over 80% longer die life compared to their sintered counterparts.

References: Chinese Library Classification: TB31; TG115.2 Document Code: A Article ID: 1001-4012(2025)09-0001-06 ; Mechanical Properties Characterization of Molybdenum Alloys for Piercing Tips Prepared by Hot Pressing; Tian Jiazhi1, Zhou Hongdeng2

Stardust Technology spherical molybdenum alloy powder is produced using advanced radiofrequency plasma spheroidization technology. It features high purity, low oxygen content, and high sphericity. The powder exhibits a smooth surface free of satellite particles, uniform particle size distribution, excellent flowability, and high bulk and tapped densities. Combining the high-temperature resistance, corrosion resistance, and excellent mechanical properties of molybdenum alloys, it finds extensive applications in additive manufacturing, powder metallurgy, thermal spraying, electronics, and nuclear industries. Its core advantages lie in mature and reliable technology, absence of electrode contamination, and ability to meet stringent material requirements for high-end manufacturing, delivering stable application performance.For more product details, please contact our professional manager Cathie Zheng, at +86 13318326187.