Refractory metals refer to metals with a melting point above 2000 ℃, including tungsten, molybdenum, tantalum, niobium, rhenium and vanadium. This article only covers the first 5. The common characteristics of refractory metals and their alloys are high melting point, high high temperature strength, good resistance to liquid metal corrosion, and most of them can be processed plastically. Their use temperature range is 1100~3320 ℃, which is much higher than high temperature alloys. They are important high temperature structural materials for aerospace.

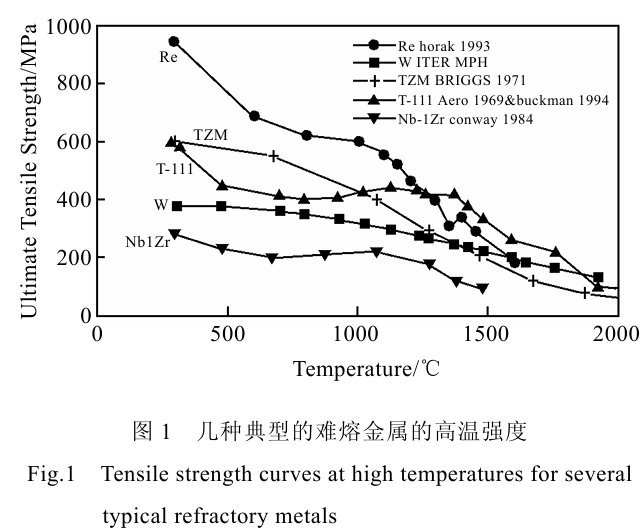

The use temperature of refractory metals and their alloys is directly related to their melting point. The order from low to high is: niobium alloy → molybdenum alloy → tantalum alloy → tungsten alloy (rhenium metal). Rhenium is a material with high price, fast work hardening and difficult plastic processing. Affected by density and machinability, the most commonly used alloys are niobium alloys and molybdenum alloys. Figure 1 shows the relationship between temperature and high temperature strength of several typical refractory metal materials. It can be seen that with the increase of the use temperature, the high temperature strength of tungsten alloy decreases the slowest, tantalum alloy is slightly faster, and the faster decreases are rhenium, molybdenum alloy, and niobium alloy.

1 Tantalum alloy

Tantalum alloy has the characteristics of high temperature strength, good thermal shock resistance and creep strength, small expansion coefficient, good thermal shock resistance, and excellent plasticity and toughness, but the alloy is not resistant to oxidation above 500 ℃, and it is necessary to apply an anti-oxidation coating on its surface for protection.

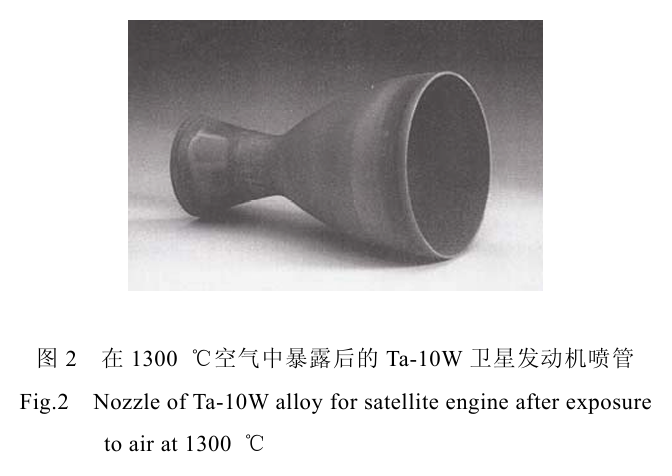

In order to meet the requirements of high temperature strength and high temperature creep performance, the United States has successively developed Ta-10W, Ta-12W, T-111, T-222, and ASTAR-811C alloys; in addition to the above alloys, the former Soviet Union has added Ta-3Nb-7.5V, Ta-15W, Ta-20W, and Ta-10Hf-5W alloys. Ta-10W alloy has been used in the combustion chamber of the Agena spacecraft and the nose cone of the missile (the operating temperature is about 2500 ℃) (see Figure 2), the gas spoiler of the rocket engine nozzle, and the combustion chamber of Apollo [1] (see Figure 2); Ta-10W-2.5Hf alloy is used for the nozzle of the liquid rocket nozzle. Unlike niobium alloy and molybdenum alloy, tantalum alloy has high long-term creep strength above 1204 ℃, so it is used as a power conversion material for large-scale nuclear power systems in space. For example, Ta-10W is used as a reinforced structural material for aerospace nuclear power devices,

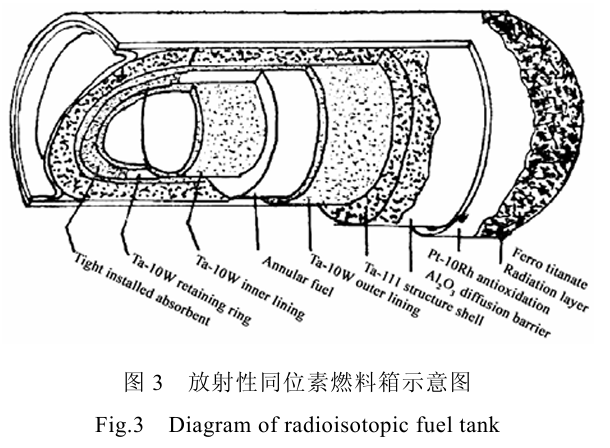

T-111 (Ta-8W-2Hf) is used as a reinforced structural material for wrapping the heat source of a thermal engine for space (see Figure 3 for a schematic diagram), T-222 (Ta-10W-2.5Hf-0.01C) is a material developed for the power generation device of the Pluto probe, and ASTAR-811C (Ta-8W-1Re-1Hf-0.025C) is a material with better high-temperature creep strength [2,3]. Since the late 1960s, my country has developed a series of Ta-W alloys, including Ta-7.5, Ta-10, Ta-12W and Ta-8W-0.5Hf alloys [4-6].

The coating of tantalum alloy is similar to that of niobium alloy, and the research on tantalum-niobium coating is mainly based on niobium alloy. The multi-component refractory metal compounds of tantalum alloys show good oxidation resistance under static air conditions. For example, the Hf-Ta coating and R515 (Hf-Ta-Si) coating of Syvania Company in the United States, and the Mo-W-Ti-V coating prepared by Solar Company on T-222 tantalum alloy substrate have an anti-oxidation time of 1.75 h in static air at 1822 ℃; the Mo-Si-Ti coating prepared by V.S.Terentieva et al. can withstand an oxidizing atmosphere at 1775 ℃ for 2 h without significant changes. The main reason for the improvement of anti-oxidation performance is that the Mo-Si2, SiTi0.4-0.95, and TiSi2 phases seal the cracks around the high-temperature resistant phase Ti0.4-0.95Mo0.05-0.6Si2; the Mo-Pd, Mo-Hf, and Si-Hf coatings of the Russian Composite Materials Research and Production Association have an anti-oxidation time of more than 40 h in static air at 1700 ℃. The Mo-Zr series coating developed in my country can be used for 10 h at 1800 ℃.

2 Niobium alloy

Niobium alloy is the material with the lowest density among refractory metals. It has high strength at 1100~1650℃ and good welding performance. It has good room temperature plasticity and can be made into thin plates and parts with complex shapes. Therefore, it can be used as the preferred thermal protection material and structural material in hypersonic aircraft, spacecraft, satellites, missiles and supersonic low-altitude rockets.

For aerospace applications, the niobium alloys developed by the United States and the former Soviet Union are self-contained systems, and 20 niobium alloys have been developed respectively. The niobium alloys of the United States use W, Mo, and Hf as the main strengthening elements, and the Russian niobium alloys use W, Mo, and Zr as the main elements.

The second phase strengthening of niobium alloys is mainly carbide strengthening. Niobium alloys are divided into low-strength, medium-strength, and high-strength niobium alloys according to the strength of the alloy, and low-density and high-density niobium alloys according to the density. Niobium alloys are mainly used as bicomponent liquid rocket engines with high specific impulse, multiple starts, and adjustable thrust.

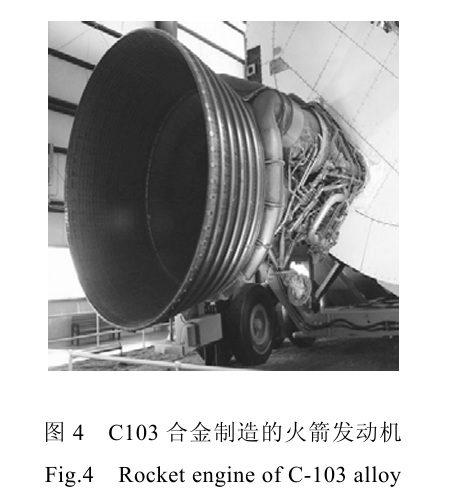

The most widely used alloy in the United States is C103 (Nb-10Hf-1Ti-0.5Zr), which has a service temperature between 1200 and 1400 °C and is a low-strength niobium alloy. More than 90% of the niobium alloys in the United States are medium-high-strength niobium alloys with a tungsten content of 10% to 30%. Its high-temperature strength ranges from 77 MPa at 1410 °C to 372 MPa at 1315 °C. Figure 4 shows a rocket engine made of C103 alloy. In terms of low-density niobium alloy research, the United States has developed Nb-37.7Ti-5Hf-5V-5Cr-5Al-2Sn-0.5Zr-0.1C, which can be used at 1250 °C for 100 h and has been used in aircraft engines. The most widely used niobium alloy in the former Soviet Union is 5ΒMЦ (Nb-5W-2Mo-1Zr) alloy, which has the same density as C103 and is a medium-strength niobium alloy with an operating temperature of 1200~1650℃ and can work at 2000℃ for a short time. The niobium alloy developed by Russia mainly uses 5%~15%W or 3%~11%Mo to strengthen the niobium alloy, with strength ranging from 260 MPa at 1100℃ to 310 MPa at 1200℃. Russia has developed low-density niobium alloys (Nb-31Ti-7Al-4V-1.5Zr, Nb-41Ti-5Al) [7-11]. The weldable high-heat-strength cast niobium alloy developed has a chemical composition of Nb-7W-2Mo-xZr-yCo. The alloy has a tensile strength of 190 MPa at 1200 °C, a 5 h endurance strength of 83 MPa at 1500 °C, and a 50 h endurance strength of 29 MPa. The high-strength niobium alloy Nb-15W-3.5Mo-1Zr has a tensile strength of 60 MPa at 2000 °C[12-16]. To meet the needs of the aerospace industry, my country has developed eight structural materials for rocket engines, including Nb-752, SCb-291, D43, C-103, C-129Y, Nb521, Nb521C, and low-density niobium alloys. Among them, C-103 and Nb521 alloys are the most commonly used. To meet the requirements of reducing the weight of aerospace engines, my country has developed low-density niobium alloys with a density of less than 6 g/cm3 and can be used below 1100 °C [17-19].

Poor oxidation resistance is the main obstacle to the long-term use of niobium alloys at high temperatures. The operating temperature of modern structural niobium alloys is 1100~1600 °C. When working in air or other oxidizing atmospheres, reliable anti-oxidation protection measures must be taken. Compared with improving the performance of the alloy, it is more important to develop a coating with a long life and resistance to higher temperatures. Improving the performance of the coating can expand the scope of use of niobium alloys. Among the niobium alloy silicide coatings, MoSi2 has the best oxidation resistance. The method is to immerse the workpiece made of the alloy in a MoSi2 melt at 800 ℃, perform hydrogen reduction at this temperature, and then perform vacuum diffusion annealing at 1200 ℃ for 12 h and siliconization at 1150 ℃ for 10 h. The oxidation resistance is better when chromium silicide and titanium silicide are added. Especially for large thin-walled components, the MoSi2 coating with the best thermal stability can ensure that the working temperature reaches 1400~1500 ℃. In order to improve the reliability of the silicide coating and increase the working temperature by 200~400 ℃, refractory oxides (ZrO2, HfO2, Al2O3) or enamel layers can be applied. The niobium alloy coatings (niobium silicon and molybdenum silicon coatings) developed in my country can be kept at a static temperature of 1700 ℃ for 8~20 h[20].

3 Molybdenum alloy

Although the melting point of molybdenum is lower than that of tungsten and tantalum, it has a low density (10.2 g/cm3), a high elastic modulus (320 GPa), a small expansion coefficient, and excellent high-temperature creep performance. The alloy can be welded, and the weld strength and plasticity meet the requirements. The process performance is better than tungsten; the disadvantage is that it is embrittled at low temperature and oxidized at high temperature.

Russia has developed many types of molybdenum alloys. In addition to adding Ti, Zr, C, and Re elements, it also adds trace amounts of Ni, B, and Nb to modify the material. The alloy grades are divided very finely according to the content of alloy elements (mainly Ti and Zr). Molybdenum alloys are divided into 14 types, such as ЦМ2А (Mo-0.07~ 0.15Zr-0.07~0.3Ti-<0.004C), ЦМ3 (Mo-0.25~0.35Zr- 0.025~0.04C), ВМ3 (Mo-0.30~0.60Zr-0.80~1.30Ti-0.25~ 0.50C-1.0~1.8Nb), etc. The United States has developed relatively few types of molybdenum alloys, including TZM (Mo-0.06-0.12Zr-0.4-0.55Ti-0.01-0.03C), Mo-30W, TZC (Mo-0.06-0.12Zr-0.4-0.55Ti-0.01-0.04C), HCM (1.1Hf-0.06C), and Mo-41~50Re series alloys [21-27]. Austrian Planci Company has developed six main alloys, including TZM, Mo-30W, Mo-3Ta, Mo-3Nb, Mo-30Cu, and Mo-47Re. Russia mainly uses vacuum consumable arc melting and pressure processing methods to prepare molybdenum alloy materials, while the United States and Austria mainly use powder metallurgy and pressure processing methods.

TZM is a high-temperature structural material that has long been widely used. It has been used in the nozzles of solid fuel rocket engines, rocket nose cones, leading edges of aircraft, rudders, etc. HCM is a high-strength molybdenum alloy that has been used in aerospace applications in recent years. At 1315 °C, the tensile strength can reach 455 MPa, which is about 140 MPa higher than TZM. Molybdenum-copper alloy has good heat resistance and high high-temperature strength and has been used as a throat lining material for solid rocket engines [20-24]. The development of deep space exploration has provided a broad space for new applications of molybdenum alloys, such as the use of molybdenum alloy single crystals in space power systems.

Among all the added elements of molybdenum, only rhenium has a positive effect on the low-temperature plasticity of molybdenum; adding 5%~50%Re can simultaneously improve the strength, low-temperature plasticity and welding performance of molybdenum alloys, significantly reduce the brittle fracture tendency of molybdenum alloys after recrystallization, and significantly improve high-temperature stability, especially thermal shock resistance; molybdenum-rhenium alloys do not produce embrittlement when working in vacuum, hydrogen or inert gas environments and at high temperatures. BM3 (Mo-0.8~1.3Ti-0.3~ 0.6Zr-0.25~0.5C) alloy has a tensile strength of 120 MPa at 1800 ℃. TP-47BП (Mo-47Re) has a tensile strength of 60 MPa at 1800 ℃; components made of Mo-50Re alloy wire and sheet can be used in heaters, reflectors and workstations with temperatures up to 2400 K. These components can be manufactured and assembled by welding. In addition, Mo-41Re, Mo-47Re, Mo-50Re, Mo-5Re-0.5Hf, etc. can all be used as structural materials for rocket thrusters [28-31].

The operating temperature of the anti-oxidation coating of molybdenum alloy for aerospace is 1400~1700 ℃, and the service life ranges from a few minutes to a few hours. Experiments have shown that oxygen pressure has a great influence on the life of MoSi2 coating. It has been found that under high temperature and low pressure, the life of some protective coatings is significantly shorter than that under normal pressure. When the pressure is 133.3 Pa and the temperature is 1413 ℃, the time from normal to accelerated erosion is 15 min, and the time from normal to accelerated erosion is 2 h at 1385 ℃. From accelerated erosion to complete damage, the temperature is 1660 ℃, the time required is 15 min, and the time required at 1618 ℃ is 2 h. The life of the protective layer at 1840 ℃ under normal pressure is greater than 2 [29]. The lanthanum zirconate thermal barrier coating prepared by atmospheric plasma spraying on a molybdenum substrate can achieve a temperature difference of 120 ℃ between the top and bottom of the coating at 1450 ℃ [32].

4 Tungsten alloy

Tungsten is the most heat-resistant metal. It has a high density (19.3 g/cm3) and the highest strength among refractory metals. It has a high elastic modulus, a small expansion coefficient, and a low vapor pressure. Its disadvantages are low-temperature brittleness and high-temperature oxidation. Alloying elements can significantly improve the wear resistance and corrosion resistance of tungsten alloys. In the aerospace industry, tungsten and its alloys can be used to make rocket nozzles that do not require cooling, ion rings of ion rocket engines, jet blades and positioning rings, hot gas reflectors and gas rudders. Using tungsten instead of molybdenum as the inlet sleeve and throat lining (W-Cu) of solid rocket engines (see Figure 5) can increase the use temperature of the material from 1760 ℃ to above 3320 ℃. For example, the nozzle of the American Polaris A-3 missile is made of high-temperature resistant tungsten tubes infiltrated with 10%~15% silver; the rocket nozzles on the Apollo spacecraft are also made of tungsten. The United Aircraft Corporation of the United States has developed a tungsten-copper composite material for use as a nozzle baffle for rocket engines, which is sufficient to withstand combustion temperatures exceeding the melting point of tungsten at 3400 ℃. In addition, this material is also suitable for rocket engines, leading edges of hypersonic aircraft, and heat shielding of re-entry vehicles. It is reported that the surface of the hypersonic aircraft developed by the United States, except for the nose cone, is covered with about 400 kg of tungsten. The United Technology Center of the United States has produced a boron-coated tungsten wire that can be used in aerospace equipment. This tungsten wire has the advantages of high strength (tensile strength of 2460 MPa), low density, and high stiffness (twice that of steel and six times that of aluminum). It can be used as rocket shells and spacecraft skeletons [32].

Adding rhenium to tungsten alloys can improve the high temperature performance and room temperature ductility of tungsten, and reduce the plastic-brittle transition temperature. Most of the tungsten alloys developed by the former Soviet Union added Re, such as W-20~28Re, W-25Re-30Mo, W-3Re-0.1HfC, W-5Re-3.8ThO2, and W-24Re-3.8ThO2. Tungsten-rhenium alloys are harder than pure tungsten.

Its room temperature tensile strength is as high as 3260 MPa, and it has good wear resistance and welding performance. W-25Re has a tensile strength of 70 MPa at 2400 ℃ and was once a nuclear reactor material for space stations; tungsten-niobium alloy single crystals are used as emitters for thermal ion power supplies for deep space exploration [33-37].

In order to make tungsten work at 2000 ℃, the most promising approach is to develop a protective layer based on refractory oxides and borides, which has high strength and thermal stability. In order to prevent the nozzle from corrosion and erosion, a protective layer composed of α-WB with a mass fraction of 10%~25% and refractory oxides ZrO2, HfO2 and ThO2 is used. The basic research direction of tungsten and its alloy coatings is: to add a silicide coating with self-healing properties to the protective surface, to form a barrier layer that can inhibit the transformation of WSi2→W5Si3 on the coating interface, that is, on the substrate; to coat a mixture based on refractory oxides and silicides on the silicide coating with a barrier substrate, and this mixture can ensure that the product can work for a long time under the conditions of use [32].

5 Rhenium alloy

The melting point of rhenium is 3180 ℃, and there is no brittle critical transition temperature. It has good creep resistance under high temperature and extremely cold and hot conditions, and is suitable for ultra-high temperature and strong thermal shock working environment. Rhenium has good chemical inertness to most gases except oxygen. The room temperature tensile strength of rhenium is 1172 MPa, and it still has a strength of 48 MPa at 2200 ℃. At 2200 ℃, the engine nozzle made of rhenium can withstand 100,000 thermal fatigue cycles. Rhenium and its alloy molded parts are mainly used in aerospace components, various solid propulsion thermal components, anti-oxidation coatings, etc. Rhenium foil produced in my country has been successfully used to recover satellites. Re-Mo alloy still has high mechanical strength at 2000℃ and can be used as high-temperature components of supersonic aircraft and missiles. Metal rhenium can resist hot hydrogen corrosion and has low hydrogen permeability. It can be used to make heat exchange devices for solar rockets. Through this heat exchange device, the heat energy of solar radiation is transferred to hydrogen, and then the hydrogen is sucked into the rhenium tube, thereby generating thrust. The maximum operating temperature of the rhenium tube can reach 2500℃[38]. Since 1980, Ultramet Company in the United States has been developing a liquid rocket engine combustion chamber that can be used at 2204℃ without liquid film protection, using metal rhenium as the matrix and iridium as the coating. The nozzle prepared by chemical vapor deposition technology has been successfully used in the Hughes Space Vehicle 601HP satellite propulsion system; Kunming Precious Metals Research Institute in my country has conducted research and development of rhenium-iridium nozzles. In order to reduce the weight of the rhenium-iridium nozzle, researchers took advantage of the good thermal compatibility of metal rhenium and graphite and the plasticity of the bonding surface, and prepared the engine combustion chamber by preparing Re/Ir coating on the outer surface of C-C composite material. The project is still in the research and development stage. In recent years, super heat-resistant high-temperature alloys of rhenium have become its most important application field [39,40].

6 Conclusion

Refractory metal materials have been successfully applied in aerospace and aviation engineering and have become indispensable materials. The development of the aerospace industry will inevitably put forward new demands for refractory metal materials, among which high-temperature strength, high-temperature oxidation and protection and material lightweighting are new challenges that cannot be avoided.

The research and development of refractory metal materials with higher high-temperature strength can be achieved through alloying, composite and purification, and there is great potential for development in this area. The development of high-temperature anti-oxidation protective layers can better match the protective layer with the protected substrate (refractory metal material itself). The current situation is that the high-temperature performance of the protective layer cannot meet the material's requirements for it. Therefore, it is very important to develop a protective layer with a long service life at high temperature, because in aerospace and aviation engineering, the full play of the high-temperature mechanical properties of traditional refractory metal materials depends on the development of high-temperature anti-oxidation protective layers. Lightweighting of refractory metal materials refers to the way to reduce the density of alloys without significantly reducing the mechanical properties of alloys. This approach is of great significance for increasing the effective load of spacecraft and extending the range. It can be seen that strength, protection and lightweight are important research and development directions for refractory metal materials in the future.

Paper citation information

Rare Metal Materials and Engineering Vol. 40 No. 10 October 2011

Stardust uses spherical tungsten, molybdenum, tantalum, niobium, vanadium, rhenium, chromium and other high-end rare refractory metals and their alloys and compounds spherical powders sphericalized by radio frequency plasma. It has the characteristics of high purity and low oxygen, high sphericity, smooth surface, no satellite balls, uniform particle size distribution, excellent flow performance, etc. It can be applied to laser/electron beam additive manufacturing, laser direct deposition, hot isostatic pressing, injection molding, laser cladding and other processes. The composition and particle size can also be customized to meet the needs of customers in different fields.

For more details, please contact Vicky at +86-13318326185