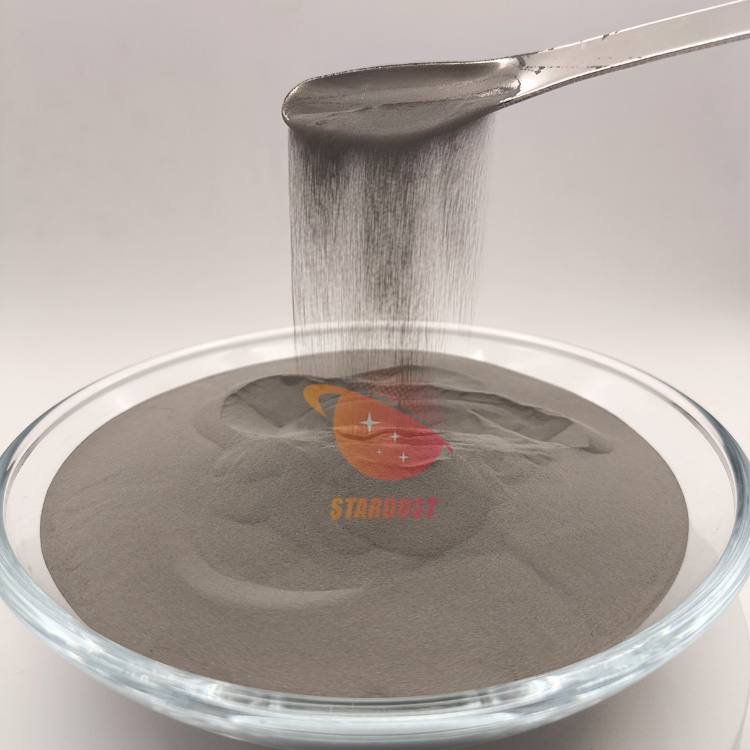

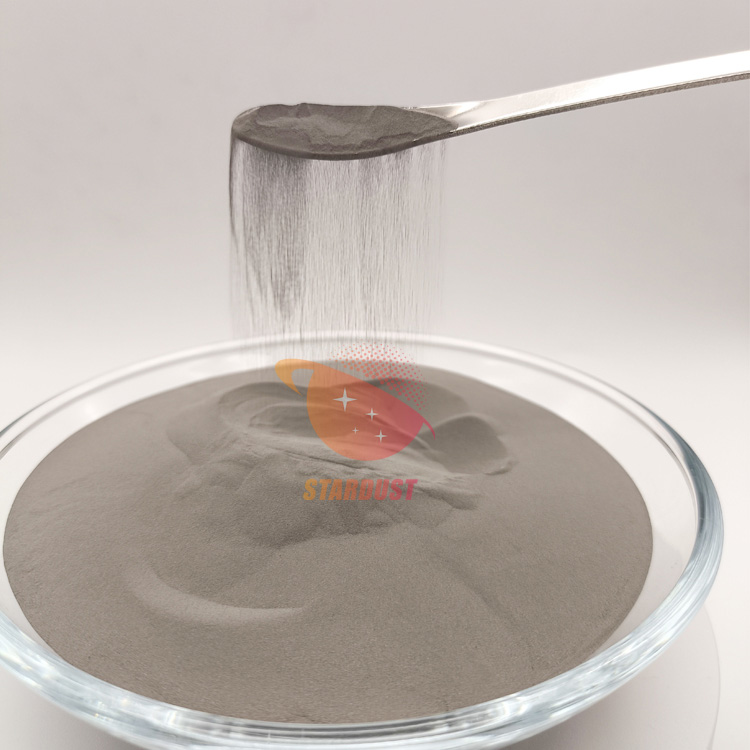

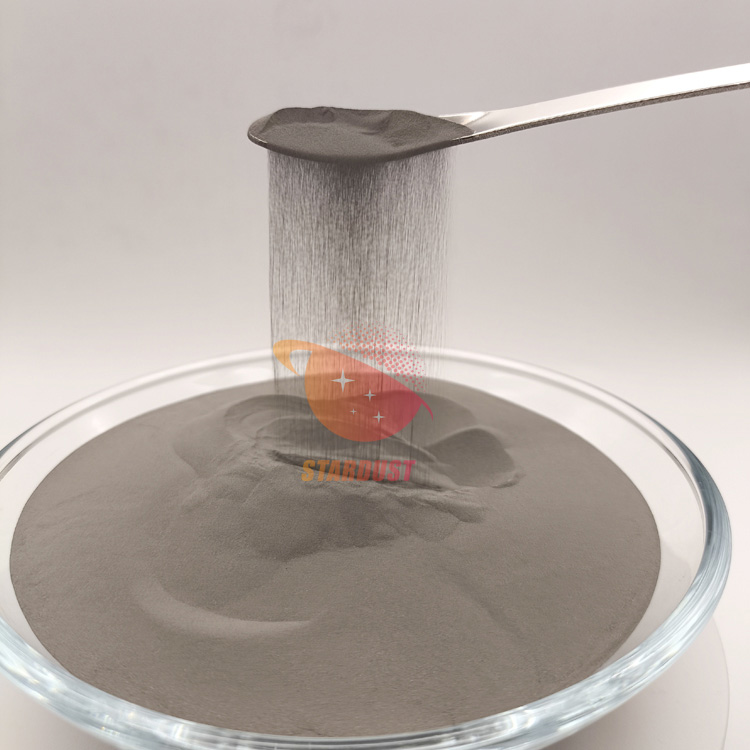

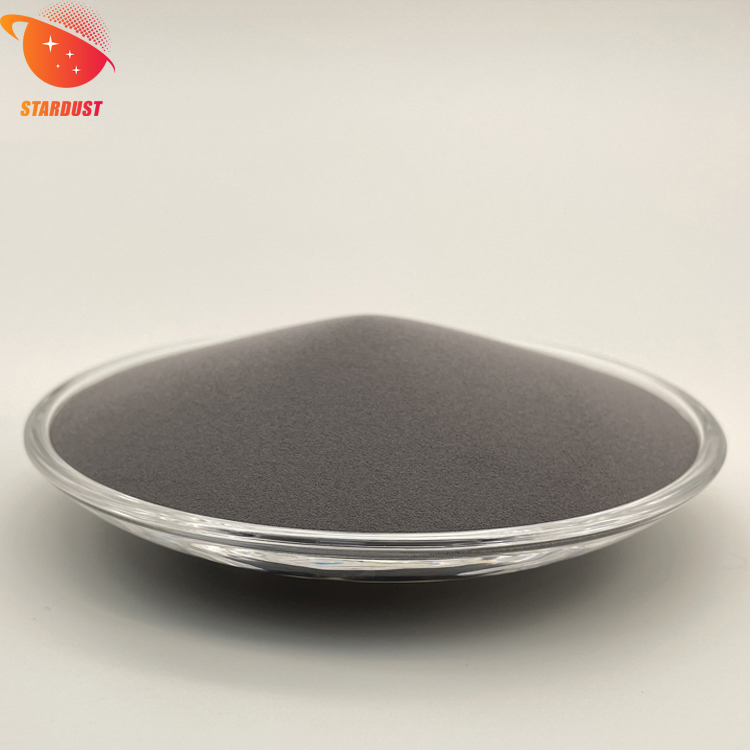

Spherical VCr₄Ti₄ alloy powder is a high-performance alloy powder composed of vanadium (V), chromium (Cr) and titanium (Ti), with excellent high-temperature stability, oxidation resistance and good mechanical properties. The alloy powder is prepared by powder metallurgy process, the particles are spherical, with good fluidity and compactness, suitable for applications such as metal injection molding (MIM) and additive manufacturing (3D printing). Spherical VCr₄Ti₄ alloy powder is widely used in the manufacture of aerospace, military and high-temperature components, and can maintain excellent performance in extreme temperature and high-pressure environments.

Item No :

Spherical VCr4Ti4 high entropy alloy powderOrder(MOQ) :

5kgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.VCr₄Ti₄ alloy powder is a high-performance alloy composed of vanadium (V), chromium (Cr) and titanium (Ti).

1. Characteristics

- Excellent high temperature performance: The alloy has strong high temperature resistance and can maintain good structural stability and mechanical properties at extreme temperatures.

- Oxidation resistance: The combination of titanium, chromium and vanadium elements gives the alloy excellent oxidation resistance, especially in high temperature and oxidizing environments.

- High strength and hardness: The alloy powder has high strength and hardness and is suitable for use in environments with high stress and high temperature.

- Good corrosion resistance: The alloy has good corrosion resistance and is suitable for various harsh environments, especially in industrial applications.

- Good fluidity: The alloy powder has uniform particle morphology and good fluidity, which is suitable for applications such as additive manufacturing.

2. Application fields

- Aerospace: Used for key components such as engines, high-temperature nozzles, and rocket components, which need to maintain excellent mechanical properties and structural stability in high temperature environments.

- Nuclear energy field: Alloy powder is widely used in high temperature resistant and radiation resistant materials of nuclear reactors, and can work for a long time in high radiation and high temperature environments.

- Military industry: The alloy has important applications in missiles, aircraft and other high temperature and high pressure equipment, and can withstand high temperature and pressure under extreme conditions.

- Additive manufacturing and 3D printing: VCr₄Ti₄ alloy powder has good fluidity and low specific surface area, and is suitable for manufacturing processes such as 3D printing and metal injection molding (MIM) to produce parts with complex shapes.

3. Preparation method

- Radio frequency plasma spheroidization

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical refractory high entropy Ta-Nb-W alloy powder is produced by radio frequency plasma spheroidization technology. It has high purity and low oxygen, high sphericity, smooth surface, no satellite balls, very few hollow particles, uniform particle size distribution, excellent flow properties, and high loose density and tap density.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

IPv6 network supported

IPv6 network supported