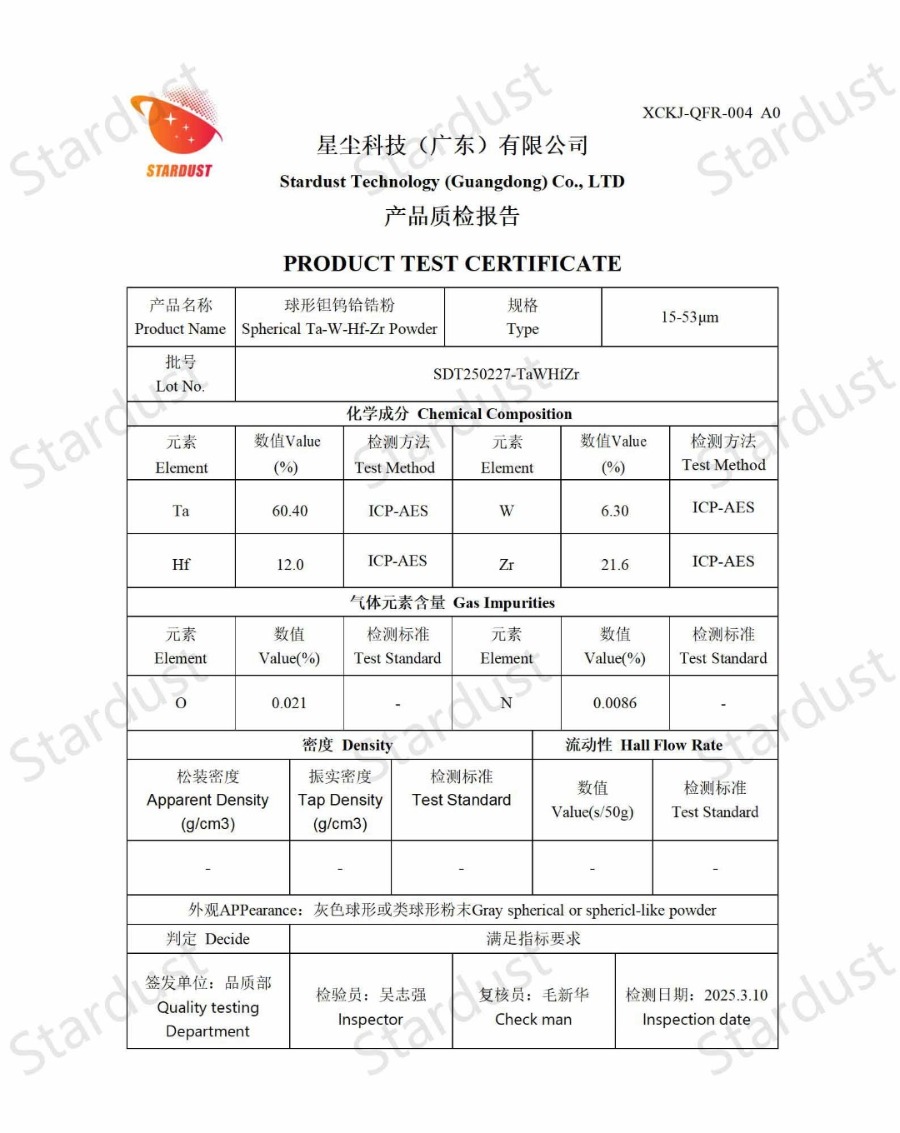

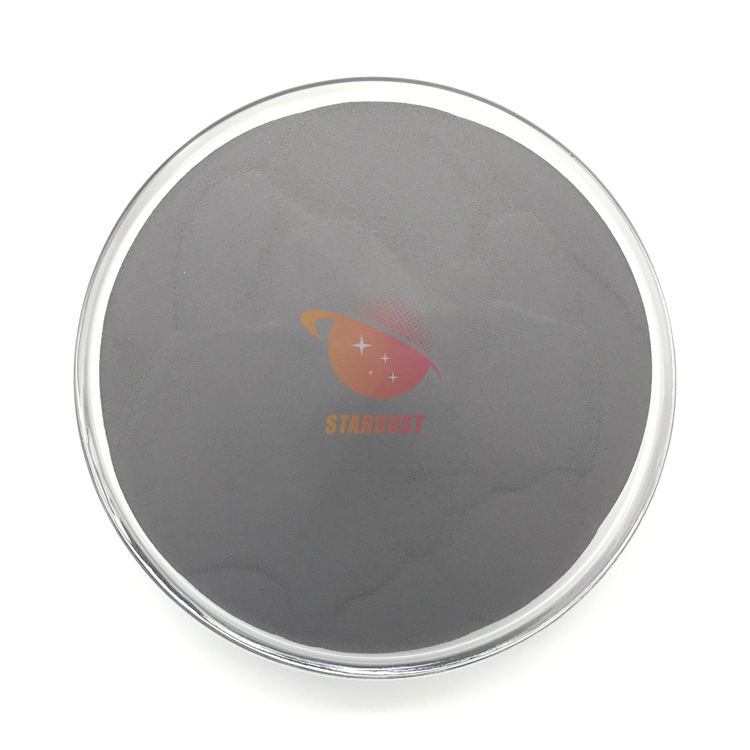

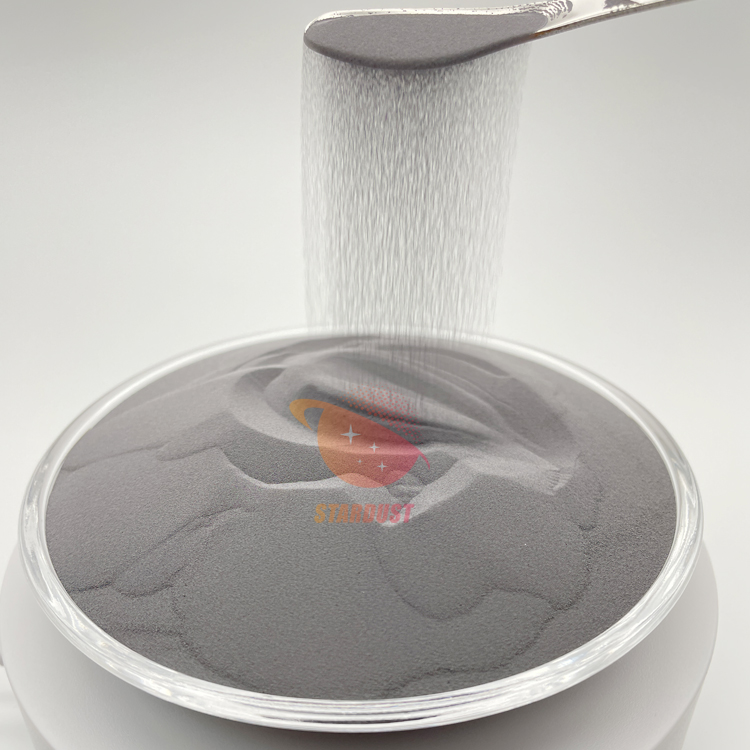

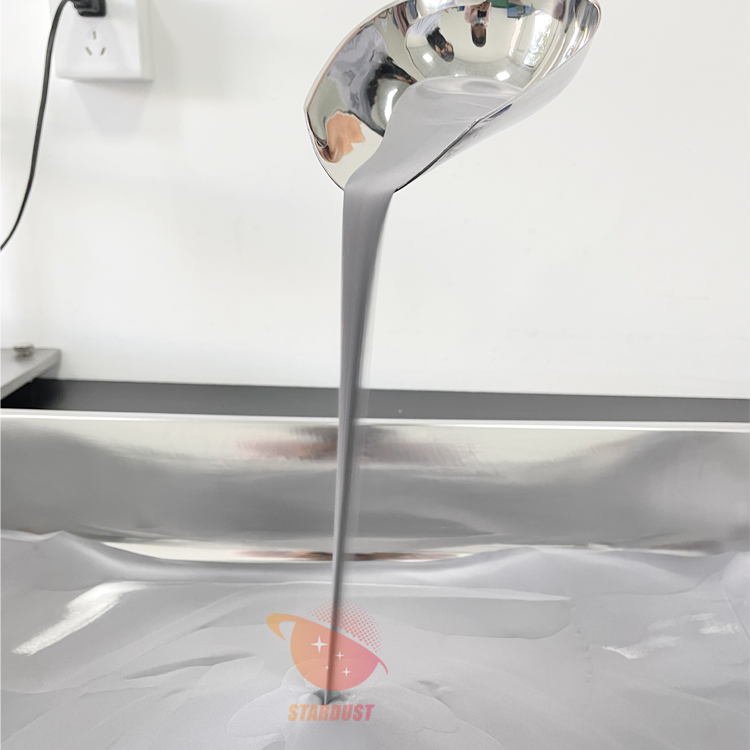

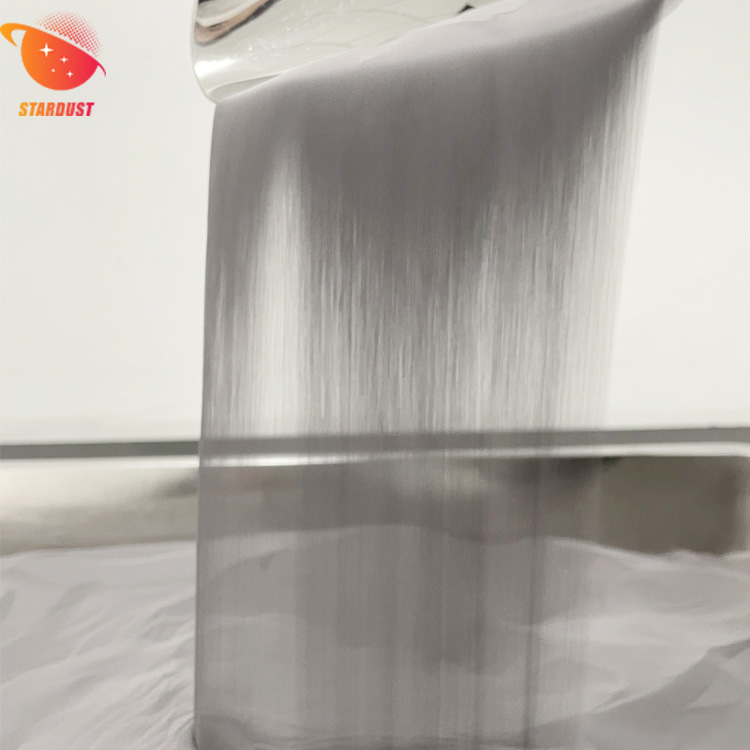

Spherical tantalum-tungsten-hafnium zirconium alloy powder is a multi-alloy system based on four refractory metal elements: tantalum (Ta), tungsten (W), hafnium (Hf), and zirconium (Zr). The typical components are TA-10W-2.5HF-0.1ZR-0.1NB-0.02Mo (such as T-122 alloy). It features high sphericity and excellent fluidity, controllable particle size, high purity and low oxygen content, high melting point and high-temperature stability, high strength and good plasticity, corrosion resistance and biocompatibility, low density and high specific strength, and other superior properties. It is mainly used in 3D printing additive manufacturing, powder metallurgy, hot isostatic pressing, etc., and can be applied in fields such as aerospace, energy and nuclear industry, electronics and advanced manufacturing, and biomedicine.

Item No :

Spherical Ta-W-Hf-Zr PowderOrder(MOQ) :

1 KgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Weight :

4 KgSpherical Ta-W-Hf-Zr Powder

I. Characteristics

1.High melting point and high-temperature stability: The alloy's melting point is as high as 3027℃, and it maintains excellent thermal stability and creep resistance within the temperature range of 93-1426℃, far exceeding that of ordinary high-temperature alloys.

2.High strength and good plasticity: At room temperature, the tensile strength reaches 773 MPa, and the elongation is 30%. It combines high strength with processing toughness, meeting the forming requirements of complex structural parts.

3.Corrosion resistance and biocompatibility: The dense oxide film (Ta₂O₅) on the surface of tantalum endows it with extremely strong chemical inertness, performing well in acidic, alkaline and body fluid environments. At the same time, it has good compatibility with human tissues and is suitable for biomedical implant applications.

4.Low density and high specific strength: With a density of 16.79 g/cm³, it is significantly lower than that of pure tungsten (19.3 g/cm³), offering a notable advantage in aerospace lightweight design.

II. Application Fields

1.Aerospace and national defense and military industry

Extreme environment structural components: As the core material of the combustion chamber and nozzles of rocket engines, it can withstand the erosion of high-temperature gas above 3000℃ and resist the corrosion of liquid oxygen/methane and other propellants.

Lightweight design: By taking advantage of its high specific strength, it is used to manufacture satellite antenna brackets and thermal protection systems for aircraft, ensuring structural reliability while reducing weight.

2.Biomedical

Orthopedic implants: The 3D-printed tantalum tungsten hafnium zirconium alloy porous scaffold has an elastic modulus similar to that of human cartilage (about 10-20 GPa), and the surface bioactive coating can promote the adhesion and growth of bone cells, significantly reducing the risk of implant loosening.

Dental restoration: The corrosion resistance and wear resistance of alloys make them ideal materials for dental roots and dentures. Long-term clinical data show that their biocompatibility is superior to that of traditional titanium alloys.

3.Energy and Nuclear industry

Nuclear reactor components: The low neutron capture cross-sections of hafnium and zirconium (105 barns and 0.18 barns respectively) make them suitable for nuclear fuel cladding materials and can serve stably in high-temperature and high-pressure water environments.

The first wall of the fusion reactor: As a candidate material, its resistance to plasma sputtering and high-temperature strength can effectively extend the service life of the fusion device.

4.Electronics and Advanced Manufacturing

Sputtering targets: In the semiconductor industry, tantalum, tungsten, hafnium and zirconium alloy targets are used to deposit barrier layers and conductive layers. Their high purity and uniformity can meet the requirements for the preparation of nanoscale films.

High-temperature sensor: By taking advantage of its high-temperature stability, the heating elements and electrodes of the temperature sensor for aero engines are manufactured to ensure precise measurement in an environment above 2000℃.

Spherical tantalum powder is prepared by RF plasma spheronization technology, featuring high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flow properties, high bulk density and high vibration density.

Read More

Spherical tantalum powder is prepared by RF plasma spheronization technology, featuring high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flow properties, high bulk density and high vibration density.

Read More

Spherical tantalum powder is prepared by RF plasma spheronization technology, featuring high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flow properties, high bulk density and high vibration density.

Read More

Spherical tantalum powder is prepared by RF plasma spheronization technology, featuring high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flow properties, high bulk density and high vibration density.

Read More

Spherical tantalum powder is prepared by RF plasma spheronization technology, featuring high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flow properties, high bulk density and high vibration density.

Read More

Spherical tantalum powder is prepared by RF plasma spheronization technology, featuring high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flow properties, high bulk density and high vibration density.

Read More

Metallurgical tantalum powder is a silver-grey powder with a metallic luster. It is mainly composed of high-purity tantalum elements and has the characteristics of high melting point, strong corrosion resistance, large specific capacitance, and good ductility. It is a key basic material for the production of tantalum capacitors, tantalum alloy products and other electronic components and high-end alloy materials. It plays an important role in many fields such as electronics, aerospace, and chemical industry.

Read More

Metallurgical tantalum powder is a silver-grey powder with a metallic luster. It is mainly composed of high-purity tantalum elements and has the characteristics of high melting point, strong corrosion resistance, large specific capacitance, and good ductility. It is a key basic material for the production of tantalum capacitors, tantalum alloy products and other electronic components and high-end alloy materials. It plays an important role in many fields such as electronics, aerospace, and chemical industry.

Read More

IPv6 network supported

IPv6 network supported