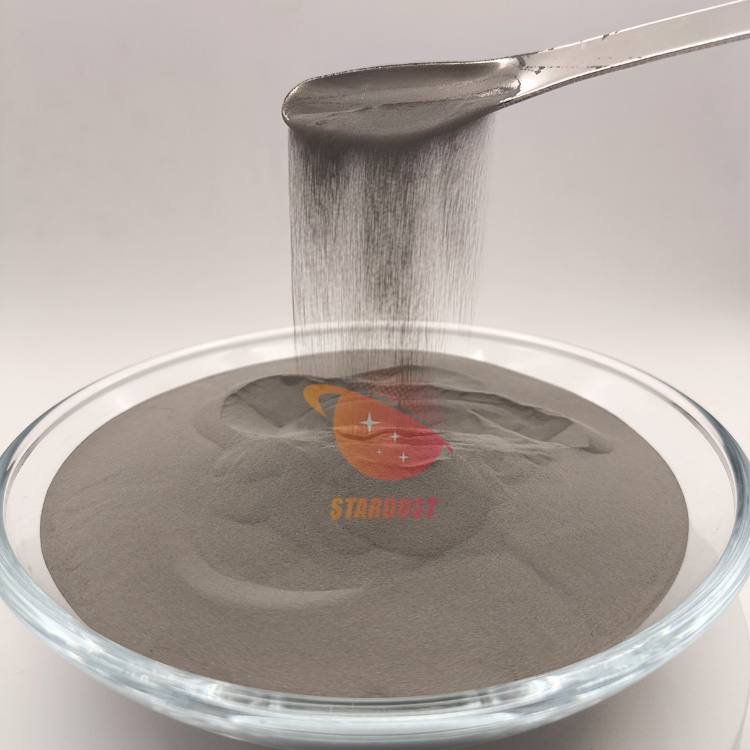

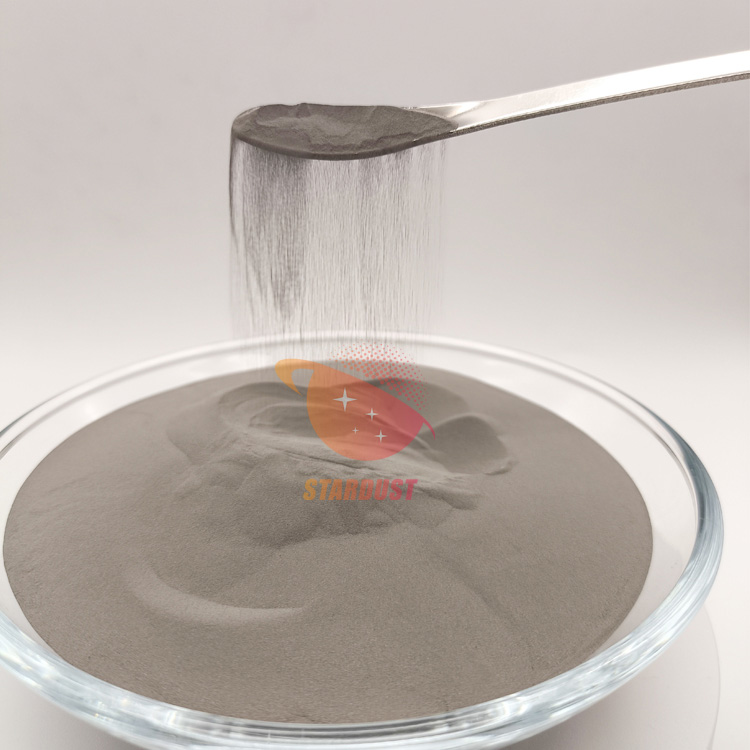

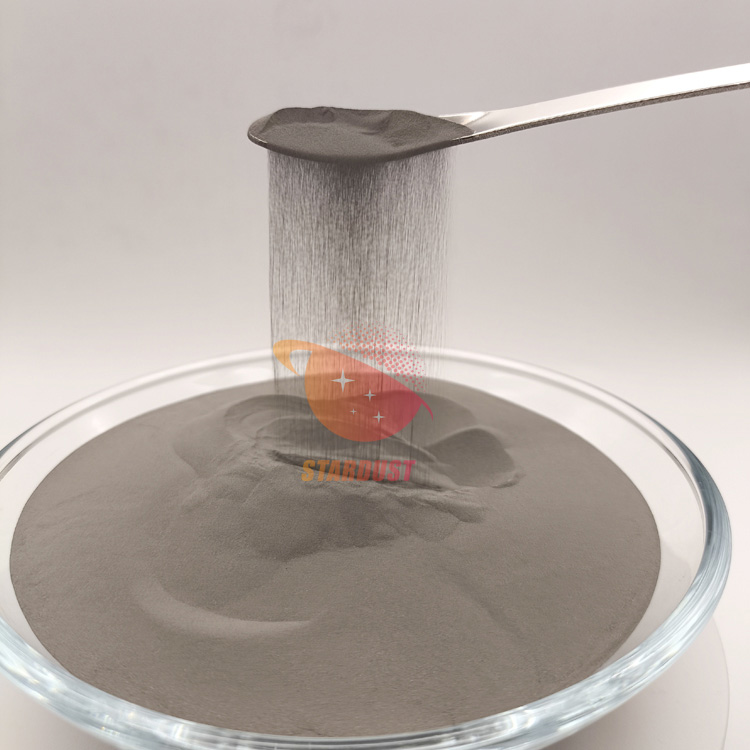

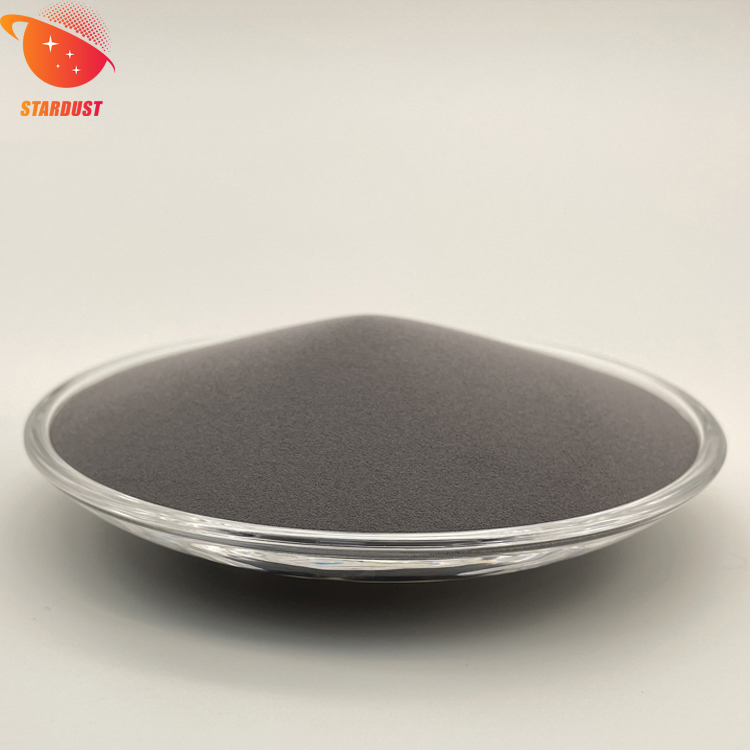

Aluminum-molybdenum-niobium-tantalum-titanium-zirconium alloy powder is a high-entropy alloy powder system composed of six metal elements: aluminum (Al), molybdenum (Mo), niobium (Nb), tantalum (Ta), titanium (Ti), and zirconium (Zr). This alloy, relying on the synergistic effect of multiple elements, breaks through the performance limitations of traditional alloys and achieves significant improvements in mechanical properties, corrosion resistance, high-temperature resistance, etc., becoming a key material in high-end manufacturing fields such as aerospace, energy, and chemical engineering.

Item No :

Aluminum-molybdenum-niobium-tantalum-titanium-zirconium alloy 15-53μmOrder(MOQ) :

1 KgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Aluminum-molybdenum-niobium-tantalum-titanium-zirconium alloy

I. Characteristics

Mechanical properties: A perfect balance of high strength and high toughness

2. Corrosion resistance: Outstanding performance in corrosion resistance across all media

3. High-temperature performance: Excellent thermal stability and oxidation resistance

Ii. Application Fields

Aerospace: It is used to manufacture hot-end components such as combustion chambers, turbine blades, and guide vanes for aero engines.

2. Energy: It can be used as material for fuel cladding, control rods, core structural components, etc. In the field of fuel cells, it can also be used as bipolar plate material.

3. Chemical industry: Applied in chemical reactors, heat exchangers, pipelines, valves and other equipment, as well as catalyst carriers.

4. Biomedicine: It is used in the manufacture of artificial joints (such as hip and knee joints), spinal fuses, internal bone fixation devices, etc., and dental implants.

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical refractory high entropy Ta-Nb-W alloy powder is produced by radio frequency plasma spheroidization technology. It has high purity and low oxygen, high sphericity, smooth surface, no satellite balls, very few hollow particles, uniform particle size distribution, excellent flow properties, and high loose density and tap density.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

IPv6 network supported

IPv6 network supported