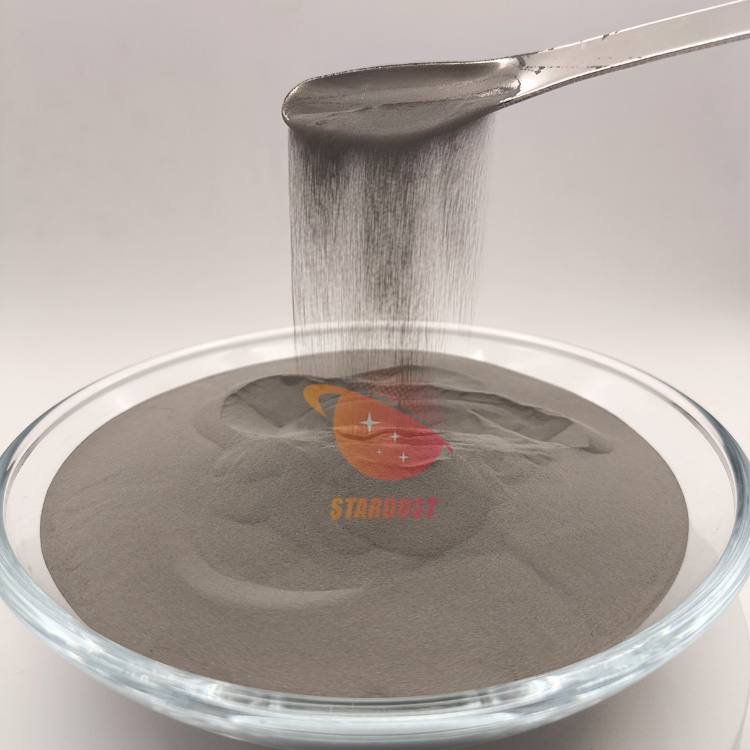

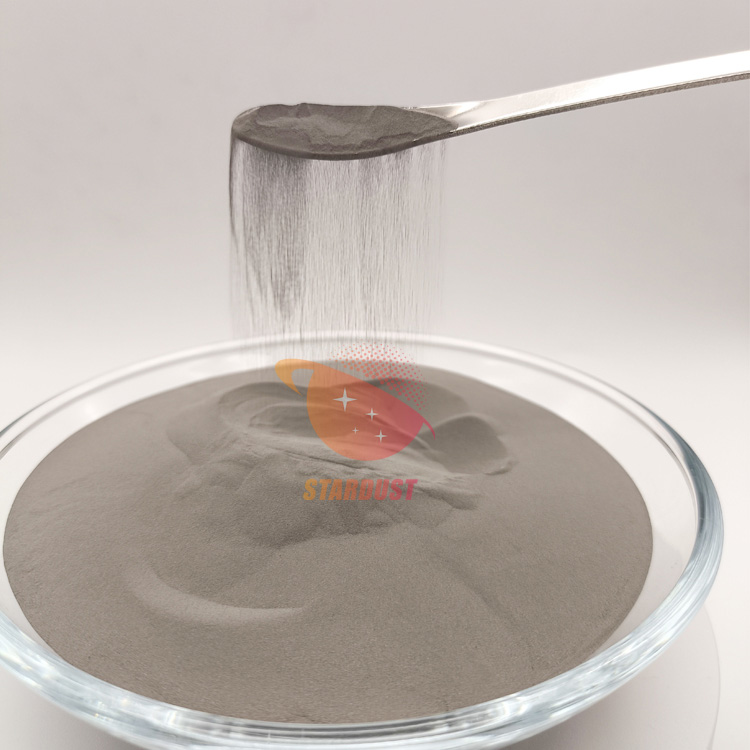

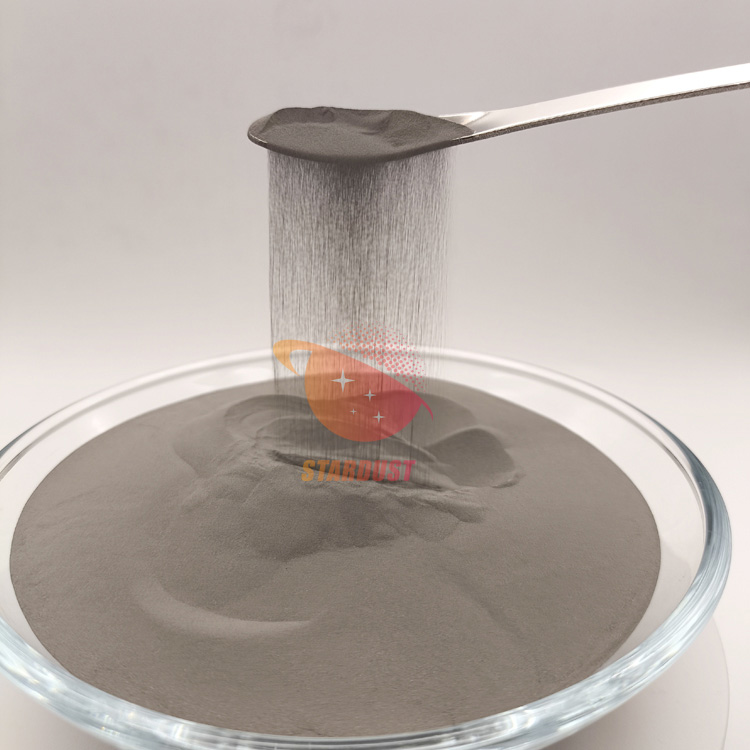

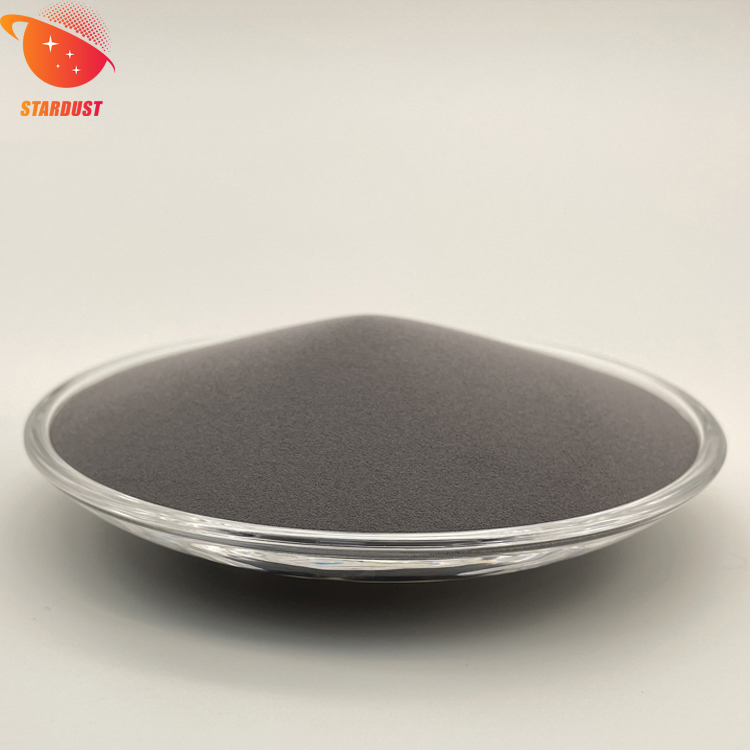

Titanium-zirconium-niobium-tantalum-nickel alloy is a multi-element alloy system composed of five metal elements: titanium (Ti), zirconium (Zr), niobium (Nb), tantalum (Ta), and nickel (Ni). This alloy has achieved multi-dimensional optimization of mechanical properties, corrosion resistance, biocompatibility and processing performance through the synergistic effect among elements, and has shown great application potential in fields such as aerospace, biomedicine, chemical engineering and energy.

Item No :

Titanium-zirconium-niobium-tantalum-nickel alloy 45-150μmOrder(MOQ) :

1 KgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Titanium-zirconium-niobium-tantalum-nickel alloy

I. Characteristics

Mechanical properties: A balance between high strength and good toughness

2. Corrosion resistance: Advantage in corrosion resistance across all media

3. Biocompatibility: An ideal choice for medical materials

Ii. Application Fields \ n \ n

1. Biomedical field: It can be used to manufacture orthopedic implants, dental implants, and cardiovascular stents.

2. Aerospace field: It can be used to manufacture engine components and structural parts.

3. Chemical industry: It can be used to manufacture corrosion-resistant equipment and catalyst carriers.

4. Energy field: It can be used to manufacture component materials such as fuel casings, fuel cells, and control rods.

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical refractory high entropy Ta-Nb-W alloy powder is produced by radio frequency plasma spheroidization technology. It has high purity and low oxygen, high sphericity, smooth surface, no satellite balls, very few hollow particles, uniform particle size distribution, excellent flow properties, and high loose density and tap density.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb alloy powder is a metal powder that is often used in the manufacture of reinforced materials or for special industrial applications. This alloy powder is usually composed of elements such as tungsten (W), molybdenum (Mo), tantalum (Ta) and niobium (Nb), and the combination of these elements can provide high strength, wear resistance and corrosion resistance. The shape of the spherical powder helps improve its flowability and compactability, allowing for more uniform distribution and mixing during the manufacturing process.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

Spherical W-Mo-Ta-Nb-V alloy powder is composed of high melting point metal elements such as tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V), and has excellent high temperature stability, corrosion resistance and high strength. This alloy powder is suitable for aerospace, high temperature tools, high power electronic components and radiation protection materials. Due to its excellent thermal conductivity, electrical conductivity and wear resistance, it is widely used in the manufacture of high-performance components under extreme working conditions.

Read More

IPv6 network supported

IPv6 network supported