With the development of aerospace technology, the nozzle inlet temperature requirements for advanced aircraft engines are constantly increasing, while the weight is also being reduced. Niobium alloys have high operating temperatures, but high density and high price; titanium alloys have low density, low price, but low operating temperatures. Using only niobium or titanium alloys alone cannot meet the requirements of aircraft. Therefore, a solution that can both withstand high temperatures and reduce weight is urgently needed. The most convenient and effective way is to weld these two alloys into a composite material, which can achieve the effect of combining the advantages of niobium and titanium alloys. Currently, reports on the welding of titanium alloys and niobium alloys mainly focus on the electron beam welding of titanium alloys and C-103 niobium alloys [3].

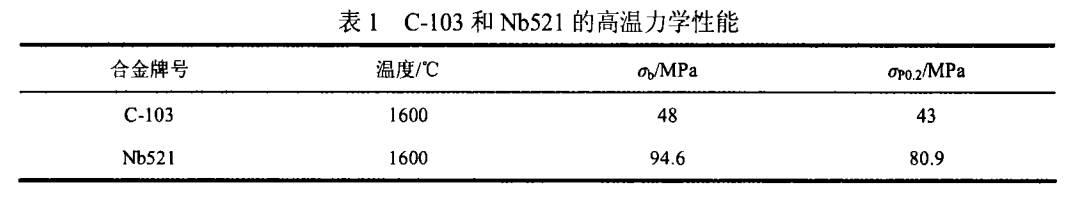

Ti3Al-based alloys not only have the characteristics of high temperature resistance, oxidation resistance, and low density (4.7g/cm²), but also have much better elastic modulus and creep resistance than Ti-based alloys. It is a very promising material to replace titanium alloys in high-temperature applications [4-5]. Nb521 niobium alloy (Nb-W-Mo-Zr) is a new niobium alloy with superior high-temperature strength compared to the commonly used C-103 niobium alloy. A comparative performance comparison is shown in Table 1. Joining Ti3Al-based alloys with Nb521 niobium alloys to form aircraft engines can achieve even better high-temperature performance and improve the engine's thrust-to-weight ratio. Therefore, studying electron beam welding between these two alloys is of great significance to the aerospace industry.

1. Experimental Materials and Methods

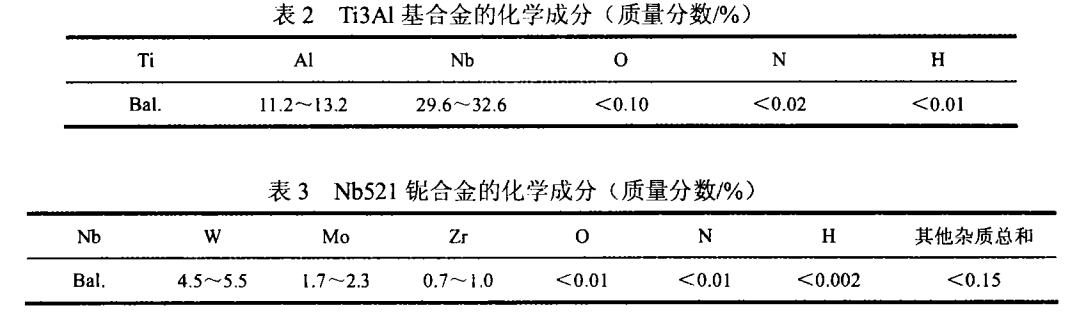

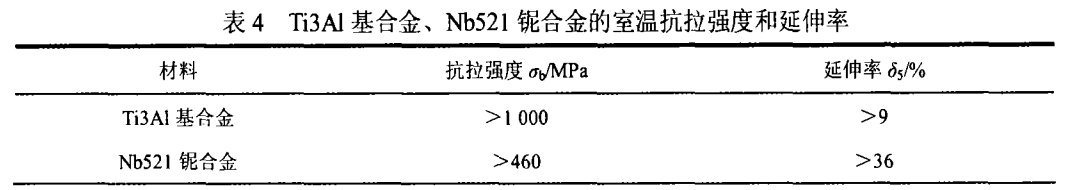

The materials used in the experiments were a Ti3Al-based alloy (Ti-23Al-17Nb, at%) developed by the Central Iron and Steel Research Institute and a Nb521 niobium alloy developed by the Northwest Research Institute of Nonferrous Metals. The chemical composition and mechanical properties of the two materials were provided by the supplier, as shown in Tables 2-4.

The welding equipment used was an EBW70015/150 electron beam welder manufactured by a German company. After welding, the metallographic structure of the weld area was observed and analyzed using a Leica microscope. Microstructure observation was performed using an S-4700N scanning electron microscope, and surface composition analysis was performed using an attached energy dispersive spectrometer (EDS). The tensile strength and elongation of the welded specimens were measured using a WE-10B hydraulic universal testing machine.

2 Electron Beam Welding Process

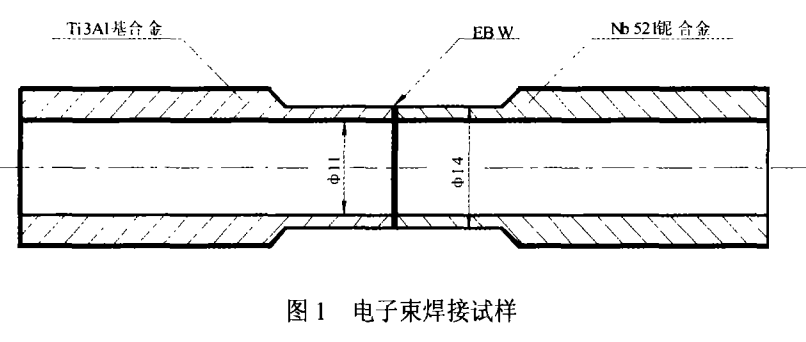

Both Ti3Al-based alloy and Nb521 niobium alloy were machined into tubular butt-welded specimens with an outer diameter of 14 mm and an inner diameter of 11 mm (see Figure 1). Before welding, the joints were cleaned with acetone to remove oil and then dried. They were secured by spot welding with V-iron, followed by vacuum electron beam welding.

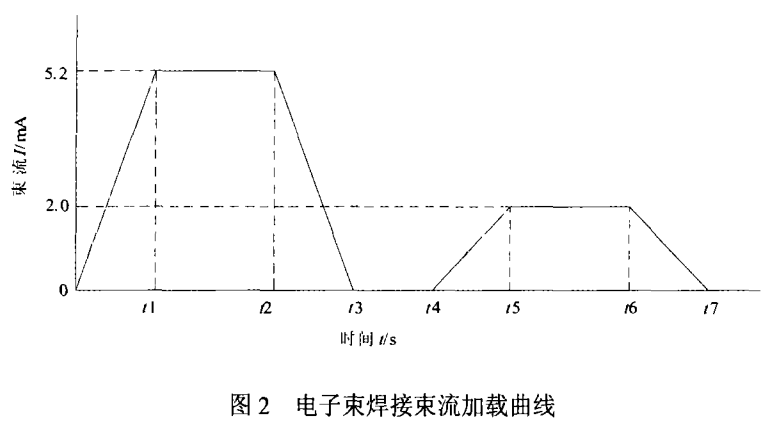

The welding process was performed in two steps according to the beam current curve (see Figure 2). Electron beam welding was first performed using a beam current of 5.2 mA, followed by touch-up welding using a beam current of 2.0 mA. The remaining parameters for electron beam welding were: accelerating voltage 150 kV, focusing current 370 mA, welding speed 11 mm/s, and vacuum 1 × 10° Pa; the remaining parameters for finishing welding were: accelerating voltage 150 kV, focusing current 380 mA, welding speed 11 mm/s, and vacuum 1 × 10° Pa.

3 Results and Analysis

3.1 Metallographic Structure Analysis of the Welded Joint

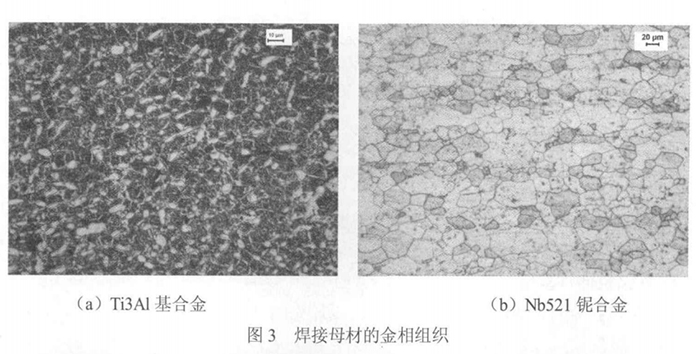

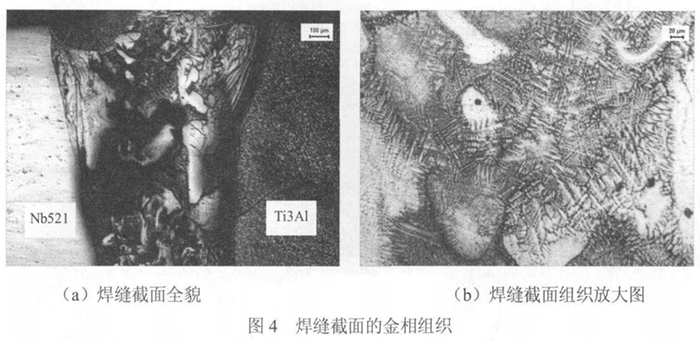

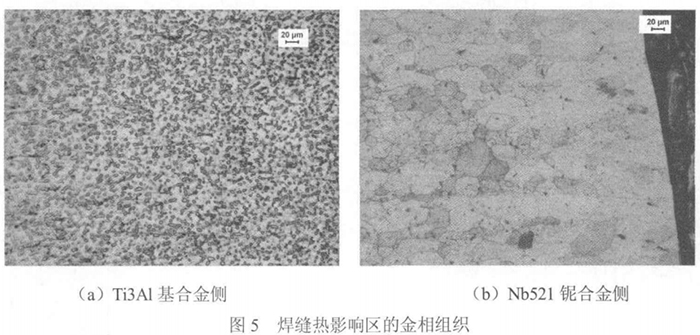

The microstructures of the two base materials before welding are shown in Figure 3. The Ti3Al-based alloy consists of equiaxed α2 phase and niobium-rich β phase; the Nb521 niobium alloy exhibits a single-phase solid solution structure with grain sizes ranging from 20 to 100 μm. The metallographic structure of the weld cross section is shown in Figure 4. The fusion zone exhibits a rapidly cooled cast structure with dendritic patterns. The microstructural characteristics of the heat-affected zone on the Ti3Al-based alloy side do not change significantly, while the grains in the heat-affected zone on the Nb521 niobium alloy side are slightly larger than those of the base material and are less susceptible to corrosion (see Figure 5).

3.2 EDS Composition Analysis of the Weld

3.2 EDS Composition Analysis of the Weld

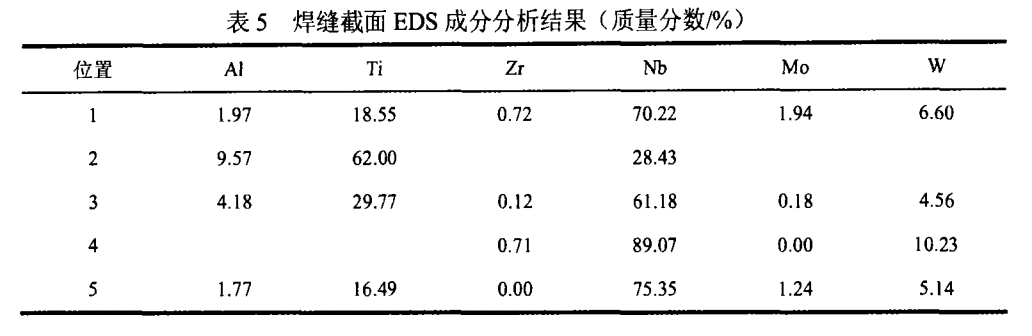

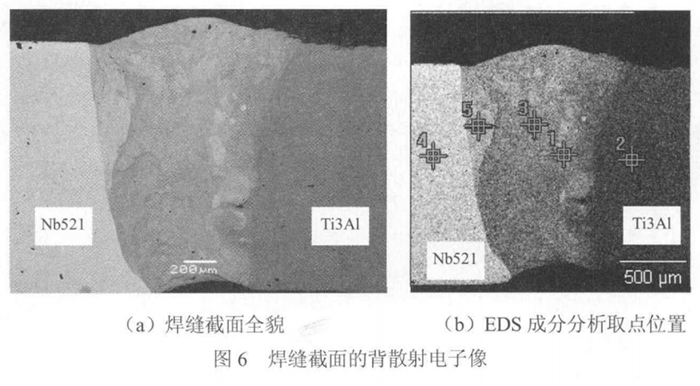

The backscattered electron image of the weld cross section is shown in Figure 6, showing obvious areas of compositional inhomogeneity. EDS composition analysis was performed on five representative locations within the weld cross section. The results are shown in Table 5. As can be seen in Figure 6b, areas 1 and 5 have high contents of the heavy element Nb, while area 3 has a high content of Ti. This indicates significant compositional inhomogeneity within the weld.

3.3 Room-Temperature Tensile Properties of the Welded Specimens

3.3 Room-Temperature Tensile Properties of the Welded Specimens

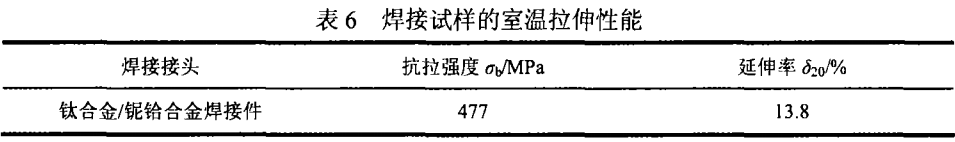

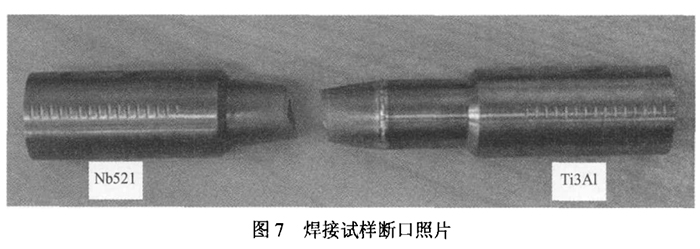

The room-temperature tensile strength and elongation of the welded specimens are shown in Table 6, and the fracture photographs are shown in Figure 7. It can be seen that the fracture occurred on the side of the parent material, the Nb521 niobium alloy. The room-temperature tensile strength of the welded joint is superior to that of the parent material, the Nb521 niobium alloy. The compositional inhomogeneity in the weld section is not sensitive to the room-temperature tensile strength. Furthermore, the elongation of the welded specimen is between that of the Ti3Al-based alloy and the Nb521 niobium alloy, demonstrating good plasticity.

4 Conclusion

(1) Ti3Al-based alloy and Nb521 niobium alloy were successfully welded by vacuum electron beam welding. The fusion zone of the weld is a rapidly cooled cast structure with dendritic patterns and a large composition inhomogeneity.

(2) The room temperature tensile strength o=477MPa and elongation 62o=13.8% of the welded specimens of Ti3Al-based alloy and Nb521 niobium alloy were obtained. The fracture occurred on the side of the parent material Nb521 niobium alloy, indicating that the tensile strength of the welded joint is better than that of the parent material Nb521 niobium alloy and the welded joint has good plasticity.

Paper Citation Information

Proceedings of the 14th National Special Processing Academic Conference

Niobium tungsten alloy Nb521 has excellent room temperature and high temperature mechanical properties and the advantages of high melting point, low density, high strength at high temperature and good machinability.

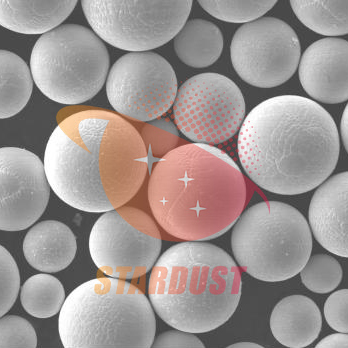

Stardust Technology's spherical Nb521 alloy powder is produced using radio frequency plasma spheroidization. It features high purity, low oxygen content, high sphericity, a smooth surface, no satellites, uniform particle size distribution, excellent flow properties, and high apparent density and vibration density.

Niobium-tungsten alloy Nb521 is widely used in the manufacture of aerospace engines, weapon thrusters, liquid bipropellant engines for rockets and missiles, nuclear reactors, submersibles, gas turbines, automotive engines, diesel engines, high-temperature furnace heating zones, high-temperature molds, high-temperature fixtures, and high-temperature crucibles.

https://www.stardustpowder.com/niobium-tungsten-alloy15-53mm

For more product details, please contact Vicky Zhang at +86-13318326185.