What is spherical alloy powder? How is the spherical alloy powder prepared?

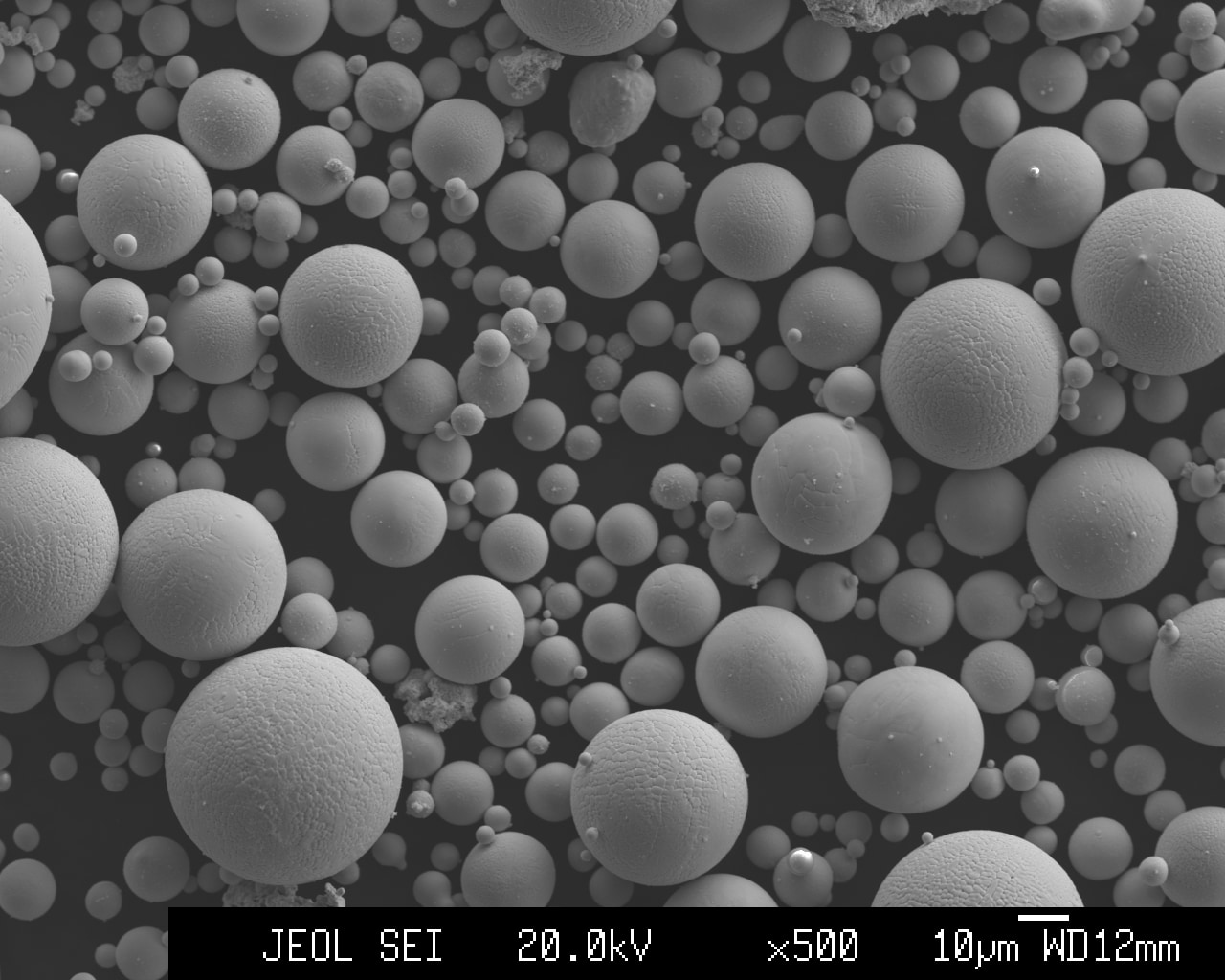

The spherical alloy powder of Stardust Technology is prepared by "RF plasma spheroidization powder making technology", which uses carrier gas to introduce cheap and irregular powder into the plasma, and uses the ultra-high temperature characteristics of the plasma to melt and cool the powder quickly to achieve spheroidization and modification of the powder. The technology has the characteristics of high product sphericity, less internal defects, controllable particle size, rich variety of raw materials, low price, low energy consumption and high yield. It is especially suitable for large-scale production of high-end rare refractory metals and spherical powder materials.

How to select particle size of spherical alloy powder?

In the process of use, due to the different particle size of the powder used in each process, such as the selection laser melting process uses 15-53μm powder, the thermal spraying process uses 15-45μm powder, the electron beam printing uses 45-105μm powder, and the ordinary powder metallurgy uses 0-150μm powder, so we need to physically separate the powder. The graded powder material can be used in aerospace, biomedical, automotive electronics, mechanical manufacturing and other fields.

What kind of spherical alloy powder has good quality?

1: High density, low porosity.

2: high sphericity, uniform particle size, better process efficiency and finished product performance.

3: Low oxygen content, no hollow satellite powder.

4: Good liquidity, suitable for complex products.

What are the spherical alloy powders? Brand of spherical alloy powder

Superalloy powder: GH4169, GH3625, GH3536, GH5188, GH3230, GH4099, GH1131, K418, K438(In738), K477, K447A, DD4, DD5, DD6, DZ125

Titanium alloy powder: TA1, TA15, TC4, TC17, TC18, TC21

Steel powder: M2, H13, M42, 316L, 304, 17-4PH, 15-5PH, 310, 420, CPM10V

Cobalt chromium alloy powder: CoCrMoW, CoCRW, CoCrMo

Aluminum powder: AISi10Mg, AlMgScZr, AISi12, 2024, 6061, 7075

Refractory powder: W, Mo, Ta, Nb, V, Si, Hf, Re

Use of spherical alloy powder

1. Aerospace field:

It is used for aircraft fan blades, compressor blades, fuselage bearing structural parts, landing gear, and high thrust-to-weight ratio engine turbine disc, compressor disc, turbine baffle, rocket nozzle, etc.

2. Nuclear industry:

Used for nuclear fuel, neutron control materials and shielding materials, neutron deceleration materials and reflection materials, nuclear reactor fuel element cladding and bearings.

3. Biomedical field

4. 3D printing field:

Metal printing consumables for LENs (DMD), EBDM, SLM technology are also used in the field of high-performance direct forming and rapid repair of complex integral components, coating and adding feature structures.

5. Automotive industry:

Such as auto parts.

6. Other areas

Used for metal powder injection forming, laser forming and other powder metallurgy dense parts.

Stardust Technology (Guangdong) Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of high-end spherical powder materials for 3D printing, powder metallurgy, surface engineering and other fields. The products have been developed: tungsten, molybdenum, tantalum, niobium, chromium, titanium, rhenium, hafnium and other metal spherical powder. At present, Stardust Technology has established long-term cooperative relations with a number of scientific research institutions, aerospace units and many manufacturing enterprises. Products cover high-end rare refractory metal and compound spherical powder. A complete range of products can meet various customer research and development, testing, production, consumption and other personalized material needs. Products enjoy a high reputation in the industry. Formulate 9 national, industry and group standards for products, and authorize 8 invention patents, covering all aspects of preparation technology, products and applications. The company has passed ISO9001 quality management system certification; And become a member of China Medical Device Industry Association in 2020.

3D printing metal powder materials, tantalum biological implant materials, high-end rare refractory metal spherical powder, welcome to contact Cathie 13318326187 (Wechat/WhatsApp). We will be enthusiastic to provide you with answers and quotations.