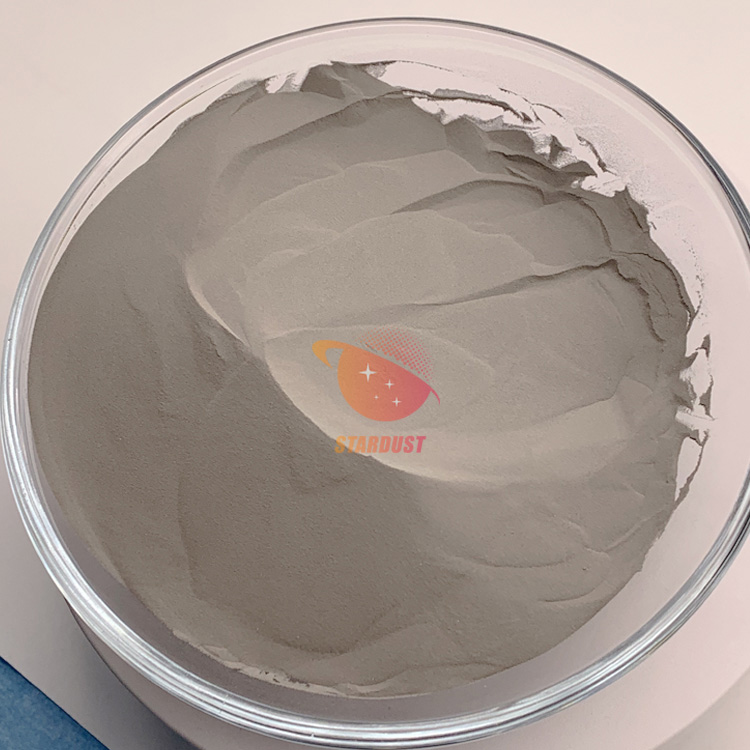

53-150μm

Hot Tags : rhenium powder rhenium alloy powder spherical rhenium powder 3d printing rhenium powder additive manufacturing rhenium powder rhenium

Read More

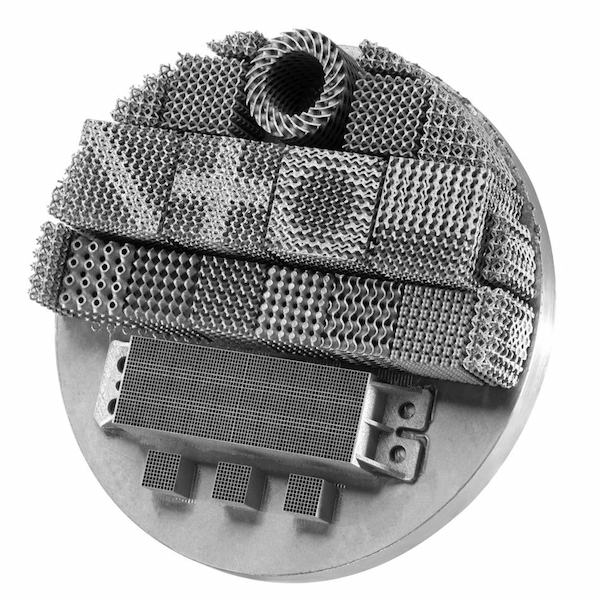

To achieve optimum flow characteristics and high packing density, an ideal Additive Manufacturing (AM) metal powder should be highly spherical in shape with no satellites. As spherical particles have minimum surface area to volume ratio this brings an added advantage in principle, of reduced surface contamination e.g. oxygen pick up. Increased particle sphericity can improve powder feeding, resulting in smoother layers, improved packing density, increased heat conduction in the powder bed and an enhanced melting profile. Generating a component by AM, also known as metal 3D Printing, relies on building the final design through a series of many thousands of layers. Whilst different metal powders can be selected according to the required performance of the final part, reproducible behavior of the powder throughout the process is key to a successful build.

Find out more

We develop handled-dimensions nanoscale powders rich in purity stage in commercial volume. Our plasma approach allows us to manufacture nanomaterials including natural metals, alloys and ceramics (oxides and non-oxides). Our accepted approach allows us to management the formula and nanostructure of our components through chemical substance allergic reactions arranged during functionality. Each and every period of our nanopowder production is strictly controled. They may be developed and manufactured in our grow to be able to fulfill the particular demands of your respective company.

Find out more

Our powder solutions allow producing metal and ceramic deposit of great purity and high occurrence by laser. Throughout each stage of your deposition approach the plasma solutions are under whole computerised management. These units are designed and made in our plants as a way to fulfill the specific requires of your organization, from investigation & advancement to manufacturing creation. These items are highly appreciated by manufacturing or investigation locations wishing to build or develop great-functionality coating deposit. d in your herb as a way to fulfill the specific requires of your organization.

Find out more

We can not only provide relatively mature research on metal spheroidization services but also provide 3D printing services , 3D printing machines and devices .

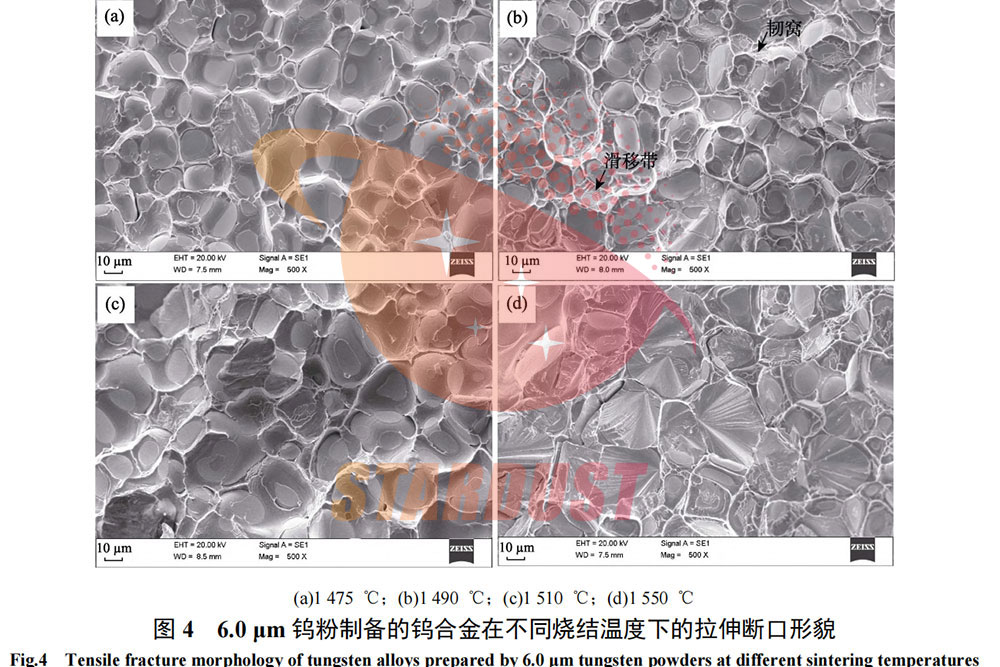

High-density tungsten alloy is an alloy with tungsten as the matrix (tungsten content is 85%~99%) and a small amount of Ni, Fe, Co, Cu, Mo, Cr, Mn and other elements added. Its density is as hi...

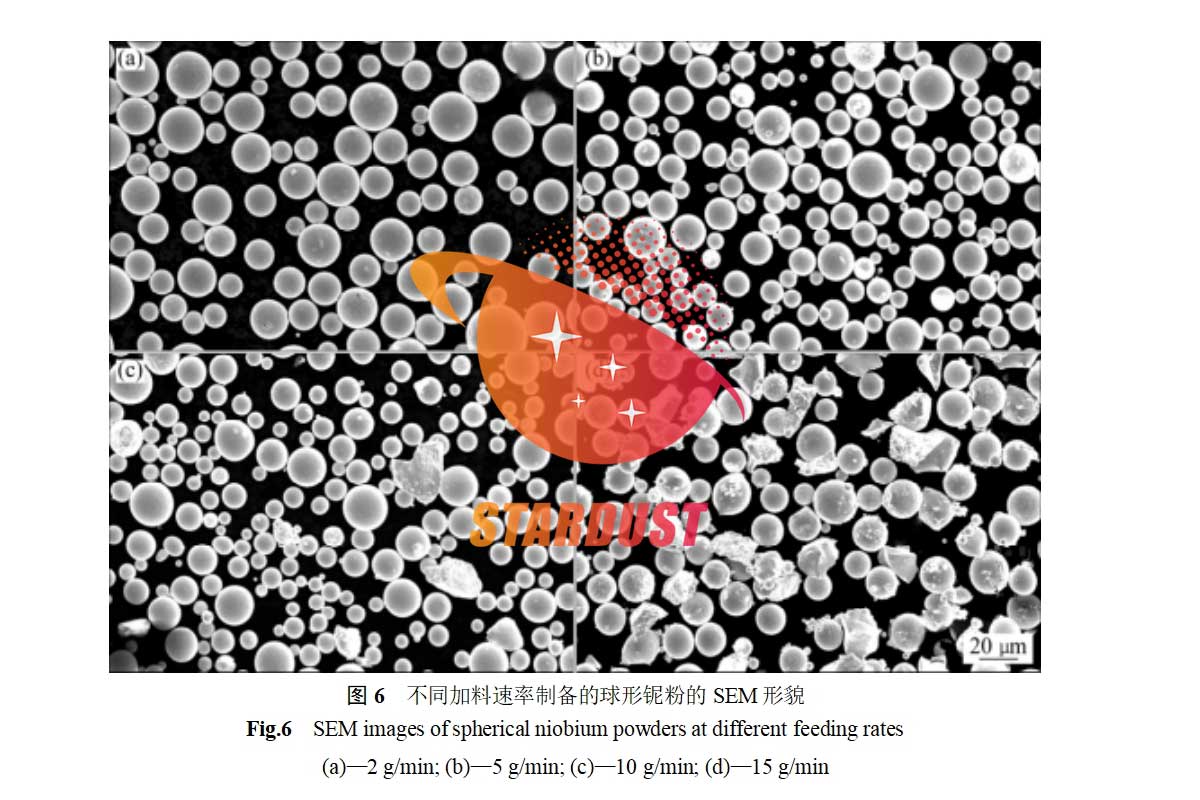

Niobium is the lightest refractory metal (density of 8.57 g/cm3), niobium and niobium alloys have high melting point, high high high temperature strength and specific strength, good room temperature m...

The term “additive manufacturing” references technologies that grow three-dimensional objects one superfine layer at a time. Each successive layer bonds to the preceding layer of melted or...

Basic Properties of Tantalum Tantalum metal is silvery white with a density of 16.654 g/cm3. Its high density is related to relative atomic mass, atomic radius and atomic volume. The relative atomic m...

IPv6 network supported

IPv6 network supported