Acetabular bone defects are a common orthopedic problem whose main etiologies include trauma, infection, tumors, and various congenital diseases [1]. This bone defect poses a great challenge to artificial total hip replacement surgery, especially in acetabular reconstruction the key to successful surgery is the selection of appropriate materials and preparation of accurate prosthesis [2]. Selection of appropriate materials and prosthesis preparation is the key to successful surgery. Tantalum is a rare metal with good high-temperature mechanical properties, chemical erosion resistance and biological tissue affinity, which has a wide range of applications in aerospace, electronics and medical fields.3D printing is a new processing method, the most obvious feature is that it can directly form the final three-dimensional samples in accordance with the model of the imported workpieces [3]. With the continuous progress of medical level and “Made in China 2025” plan to promote, additive manufacturing as a representative of the new preparation process directly promote China's orthopaedic implant market is booming. 3D printing orthopaedic tantalum has been carried out in the clinical research to promote the rapid healing of defective parts [4]. 3D printing orthopaedic tantalum metal medical devices contribute to the long-term stability of the human body and human bone, and the surgical operation of tantalum metal medical devices contribute to the long-term stability of the human body and human bone. long-term stabilization of the human body and human bone with better postoperative results [5]. In this paper, we analyze the effect of 3D printed bone trabecular porous tantalum metal produced in orthopedic medical devices.

1.Data and Methods

1.1 Clinical information

Select 20 cases of acetabular bone defect patients received in our hospital from January 2022 to December 2023 as the research object, take them all to 3D printing orthopedic tantalum metal medical devices, analyze the patients' preoperative and postoperative visual analogue scale (VisualAnalogueScale, VAS) scores, Harris Hip Score, SF-36 Quality of Life Score, postoperative complications, and complication rate. The 20 patients were 11 males and 9 females, aged 42-58 years, with a mean of (50.12±1.22) years.

Inclusion criteria: ① all informed consent; ② all patients with acetabular bone defects. Exclusion criteria: ① mental abnormalities, communication difficulties, cognitive disorders; ② accompanied by active infections, severe coagulation disorders; ③ poor cardiorespiratory function unable to tolerate surgery; ④ tantalum metal allergy; ⑤ suffering from malignant tumors and other diseases that may affect postoperative follow-up and prognosis assessment; ⑥ the presence of neuromuscular dysfunction, which may lead to postoperative hip joint instability or abnormal gait.

1.2 Methods.

A comprehensive and systematic preoperative evaluation was performed on all patients involved in the study, covering detailed history taking, physical examination, laboratory tests, and imaging examinations, steps that ensure surgical safety and individualized treatment plan development [6]. Imaging examinations included frontal and lateral radiographs of the hip joint, computed tomography, and 3D reconstruction to accurately assess the extent of the bone defect and develop an individualized surgical plan [7]. The enrolled patients were treated with 3D printed tantalum metal acetabular prosthesis.

All surgeries were performed under general anesthesia using the modified Hardinge approach. Intraoperatively, the hip joint was first exposed, the femoral head was resected, and the acetabulum was thoroughly cleaned. A 3D-printed tantalum metal acetabular prosthesis customized based on preoperative computed tomography data was precisely placed in the intended location, and bone grafting was performed using autogenous or allograft bone to fill the area of the bone defect, if necessary [8]. After fixation of the acetabular prosthesis, the corresponding femoral stem and head were fitted [9]. Finally, the joint was reset, and joint stability and mobility were carefully checked to ensure that there were no abnormalities before closing the incision layer by layer.

Postoperative management followed the concept of rapid rehabilitation. The patient's drain was removed within 24h postoperatively and anticoagulation was started to prevent deep vein thrombosis. Rehabilitation training was carried out in bed within 48h postoperatively, and the early rehabilitation training included functional movement of the lower limbs and muscle strengthening exercises [10]. Partial weight-bearing walking of the affected limbs was started in 3-5 d after surgery, and the degree of weight-bearing was gradually adjusted according to the progress of individual rehabilitation. The stitches were removed 2 weeks after the operation, and the patients were instructed to carry out the hip joint function strengthening training program.

1.3 Observation indexes and judgment criteria

①The VAS score is used to assess the degree of preoperative pain and postoperative pain of the patients. The total score is 10 points, and the higher the score, the more obvious the pain. ② Use Harris hip score to analyze patients' preoperative and postoperative function. Score value: 0~100 points, the higher the score, the better the functional recovery. ③ Apply SF-36 quality of life score to assess the patients' preoperative quality of life status, and 1-month postoperative living standard situation. It mainly includes: physiological function, psychological function, social function, environmental domain, and emotional function, with a total score of 100 points for each aspect, and the higher the score, the better the situation. ④ Analyze the occurrence of postoperative complications in patients.

1.4 Statistical analysis

The data were included in SPSS20.0 software to be analyzed, and the measurement data were expressed as x±s with t-test; the count data were expressed as % with χ2 test. p<0.05 indicated that the difference was statistically significant.

2.Results

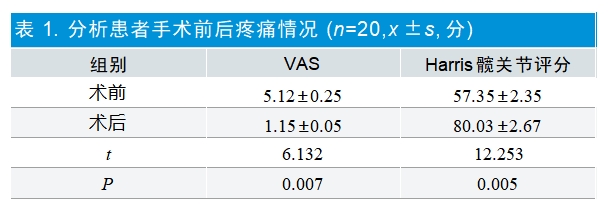

2.1 Analysis of patients' pain before and after surgery and Harris score

The results were obtained, the postoperative patients' VAS scores were significantly lower than the preoperative (P<0.05) as the difference was significant, and the patients' postoperative hip Harris hip scores were statistically significantly higher than the preoperative (P<0.05). See Table 1.

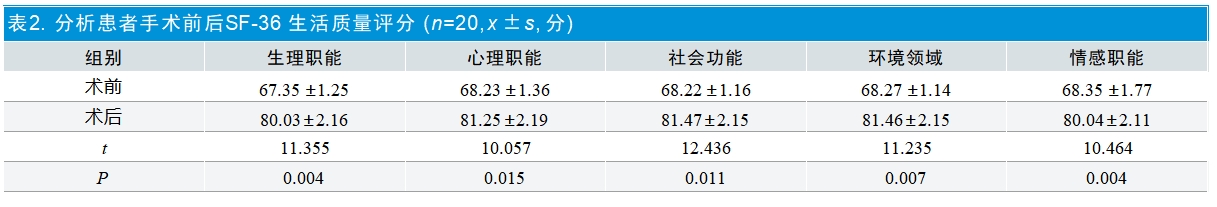

2.2 Analyzing patients' SF-36 quality of life scores before and after surgery

The results were obtained, and the SF-36 quality of life scores of patients after surgery were significantly higher than those before surgery (P<0.05) as the difference was significant and statistically significant. See Table 2.

2.3 Analysis of patient complications

In this study, all patients who received 3D printed orthopedic tantalum metal acetabular prosthesis implantation were closely followed up and monitored for complications after surgery [11]. Throughout the observation period, no patients were found to have surgical site swelling, infection, or other postoperative complications. This result tentatively suggests that the 3D printed tantalum metal acetabular prosthesis has good biocompatibility and safety. At the final follow-up, X-ray orthopantomograms were performed on all patients [12]. The examination results showed no adverse effects such as translucent lines, loosening, or osteolysis in the 3D printed orthopedic tantalum metal acetabular prosthesis and its surrounding bone tissue. These imaging findings further support the long-term stability and good integration of this type of prosthesis with bone tissue.

3.Discussion

This study investigated the clinical performance of 3D printed orthopedic tantalum metal medical devices in patients with acetabular bone defects. The results of the study showed that patients using 3D printed tantalum metal acetabular prostheses made significant progress in postoperative pain control, hip function recovery, and quality of life improvement without serious complications [13]. These results highlight the potential benefits of 3D printed tantalum metal medical devices in orthopedics, especially in complex acetabular reconstruction.

From a material science perspective, tantalum metal has unique advantages. As a rare metal, tantalum has excellent high-temperature mechanical properties, corrosion resistance, and biocompatibility. These properties make tantalum metal show great potential in the field of orthopedic implants [14]. Especially in acetabular reconstruction, tantalum's high strength and wear-resistant properties can provide long-term stability, while its good biocompatibility helps to promote the process of osseointegration. In this study, no problems such as translucent lines, loosening or osteolysis around the prosthesis were found in the postoperative follow-up, which verified the biocompatibility and stability of tantalum-metal prosthesis to some extent.

The application of 3D printing technology provides new possibilities for personalized prosthesis design and manufacturing [15]. While conventional acetabular prostheses often struggle to perfectly match complex bone defect morphologies, 3D printing technology permits the customization of precisely matched prostheses based on a patient's computed body imaging data. This highly personalized approach not only allows for greater bone preservation, but also provides better initial stability and long-term fixation. Recent clinical studies have shown that 3D-printed porous tantalum metal acetabular bone defect prostheses have demonstrated surprising therapeutic results in real-world applications, which is consistent with the findings of this study [16]. The significant improvement in the patient's postoperative Harris hip score from (57.35 ± 2.35) to (80.03 ± 2.67) in this study may be partially attributed to this precisely matched prosthesis design.

3D printing technology allows for the fabrication of prostheses with a specific porous structure. This porous structure mimics the morphology of natural bone trabeculae, which promotes bone growth and vascularization, further enhancing osseointegration [17]. Recent studies have delved into the porous tantalum laser 3D printing forming process and its biomechanical properties for orthopedic implantation, providing an important reference for optimizing prosthesis design [18]. Although the process of osseointegration was not directly observed in this study, the rapid recovery of patients' postoperative function and long-term stability indirectly support this theory. Future studies may consider directly assessing the osseointegration by imaging means or secondary surgical specimens.

In terms of clinical outcomes, the VAS scores of the patients in this study were significantly reduced from (5.12 ± 0.25) preoperatively to (1.15 ± 0.05) postoperatively, suggesting that the 3D-printed tantalum-metal acetabular prosthesis was effective in relieving patient pain. This may be related to the precise fit and good initial stability of the prosthesis, which reduces postoperative micromotion and stress masking, thus reducing pain. This result is consistent with other studies using 3D printed bone trabecular metal socket cups for total hip arthroplasty revision, further confirming the benefits of 3D printing technology in complex acetabular reconstruction [19].

In this study, the quality of life of the patients was assessed using the SF-36 quality of life score, which showed significant improvement in all aspects of physical functioning, psychological functioning, social functioning, environmental domains, and emotional functioning. This suggests that the 3D-printed tantalum metal acetabular prosthesis not only improved the patients' physical functioning, but also positively impacted their psychological well-being and social participation. This overall improvement may have stemmed from the patients' significant postoperative pain relief and restoration of hip function, allowing them to reengage in their daily activities and social life. No major complications such as infection or loosening of the prosthesis were observed during the study period. Recent biosafety studies provide an important safety rationale for the clinical application of 3D printed porous tantalum.

This study provides preliminary evidence of the feasibility and efficacy of 3D printed orthopedic tantalum medical devices for acetabular bone defect reconstruction. This novel medical device combines the excellent material properties of tantalum metal and the personalized advantages of 3D printing technology, providing a new option for complex acetabular reconstruction. However, its long-term effects and feasibility for large-scale application require further study.

However, the sample capacity included in this study was small, so the study may have certain shortcomings. And the study did not set up a control group, about 3D printing tantalum metal acetabular prosthesis and the traditional process of manufacturing titanium acetabular prosthesis in the application of the effect of the difference, yet to continue to carry out a comparative study, in order to obtain a more systematic, comprehensive, and reliable results and conclusions for the development and implementation of clinical surgical program to provide more reliable reference basis.

In the future, with the continuous progress of 3D printing technology and in-depth understanding of the biological properties of tantalum metal, this innovative medical device can bring benefits to more orthopedic patients. Meanwhile, it is necessary to continue to pay attention to the effect of its application in different types of bone defects, optimize the printing parameters and post-processing process, as well as explore its potential application in other orthopedic fields, such as spine and maxillofacial reconstruction.

Reference:

Clinical Application of 3D Printed Orthopedic Tantalum Metal Medical Devices: An Investigation of Performance

XU Fengqiang SHAN Yu LI Xuelei MA Zhijie KAO Xiaohui Beijing Chunli Zhengda Medical Devices Co.

Article Number: 1006-6586(2025)05-0141-03 Classification Number: R319,TH789 Literature Identification Number: A

Stardust Technology focuses on the research and development, production and sales of rare refractory metal spherical powder, but also provides metal 3D printing services, new product customization, etc. Welcome to consult our professional staff, Manager Zheng 13318326187.