The new high-temperature and high-ratio niobium alloy, niobium tungsten alloy, belongs to the Nb-W-Mo alloy system, like the former Soviet Union's 5BМЦ, F-48 and other alloys. It has the advantages of high melting point (2630℃), moderate density (8.9g/cm3), good high-temperature strength (σb ≥ 100MPa at 1600℃), and good processing and welding properties. Since the alloy was successfully developed by Ningxia Oriental Tantalum Industry Co., Ltd. (hereinafter referred to as "Oriental Tantalum Industry") in 1999, it has been directly applied in the field of aerospace high technology and has gradually become a widely used structural material for domestic bi-component liquid rocket engines [1-3].

At present, there are two domestic companies that produce niobium tungsten alloys in batches and on a large scale, namely Dongfang Tantalum Industry and Northwest Institute of Nonferrous Metals. Due to different production methods, the niobium tungsten alloys produced by the two companies are not exactly the same in composition and mechanical properties. The registered alloy grades are NbW5-1 (Dongfang Tantalum Industry) and NbW5-2 (Northwest Institute of Nonferrous Metals).

With the expansion of the application of niobium tungsten alloys and the year-on-year growth of demand, the standardization problem of the alloy has gradually been exposed. Due to the lack of national standards for niobium tungsten alloys, the different alloy compositions, performances, testing methods and quality evaluation standards produced by various companies, it has caused great trouble and inconvenience to aerospace users, which is not conducive to the expansion and application of this high-quality aerospace material.

In response to this situation, in March 2012, led by the China Nonferrous Metals Industry Standards and Metrology Quality Research Institute, led by Ningxia Dongfang Tantalum Industry Co., Ltd., and jointly participated by Shanghai Space Propulsion Institute, Control and Propulsion System Division of China Academy of Space Technology, and Northwest Institute of Nonferrous Metals, the drafting and formulation of the national military standard for my country's new generation of aerospace materials - "Niobium Tungsten Alloy Bar Specification for Aerospace" (hereinafter referred to as "Specification"). The Specification provides detailed provisions for the key contents of niobium tungsten alloy, such as chemical composition, density, and mechanical properties, which plays an important role in standardizing alloy production and ensuring alloy quality stability. It also provides a more convenient way for aerospace engine design and material selection.

Key contents of the Specification

1. Chemical composition

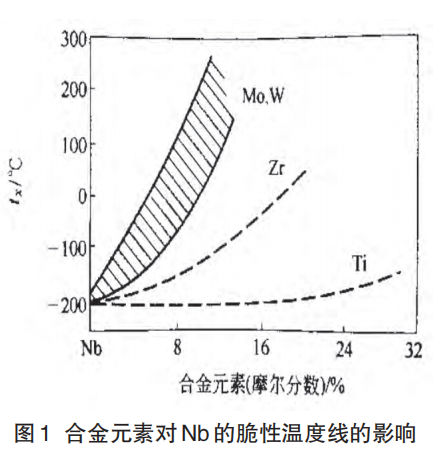

Chemical composition has a crucial influence on the performance of alloy materials. Adding W, Mo and other elements to niobium tungsten alloy to form a solid solution can improve the high temperature strength and creep performance of the alloy. Zr can form a strengthening phase with C and play a role in precipitation strengthening. However, the content of these elements needs to be controlled, otherwise it is easy to cause the alloy processing performance to deteriorate. In addition, C, N, H, O, etc., when the interstitial elements exceed a certain amount, they will cause the alloy to harden and embrittle, and they also need to be strictly controlled.

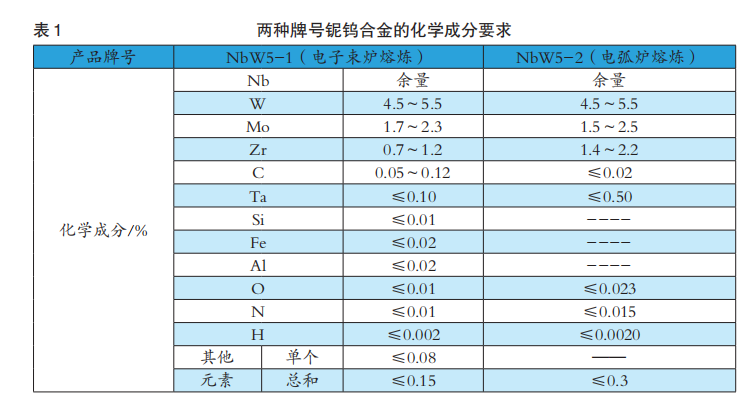

In addition, the alloy ingot smelting method also has a certain influence on the composition of the alloy. The alloy ingots smelted by electron beam furnace and arc furnace have certain differences in the content of alloying elements and interstitial elements.

After discussion and negotiation, the composition and grade of niobium tungsten alloy were finally determined as follows [4,5]:

2. Density

The density of the material is an important indicator for aerospace engine designers when selecting materials. Under the same conditions, a lower density means a lighter engine, a larger payload, and a longer on-orbit life. Therefore, "lightweighting" has always been the key optimization direction for aerospace engines. At the beginning of its development, niobium tungsten alloy was positioned as a new type of niobium-based alloy with low density and high strength.

The density test method of niobium tungsten alloy is carried out in accordance with GB/T 3850 Density test method for dense sintered metal materials and cemented carbide. The specific method uses an electronic balance and a water displacement method to measure the weight of the sample in air and water respectively. The sample density can be calculated using formula (1) [6].

ρ=Mair/(Mair-Mwater)×1g/cm3

(1) Where: ρ—density of the sample, g/cm3; Mair—mass of the sample in air, g; Mwater—mass of the sample in water, g.

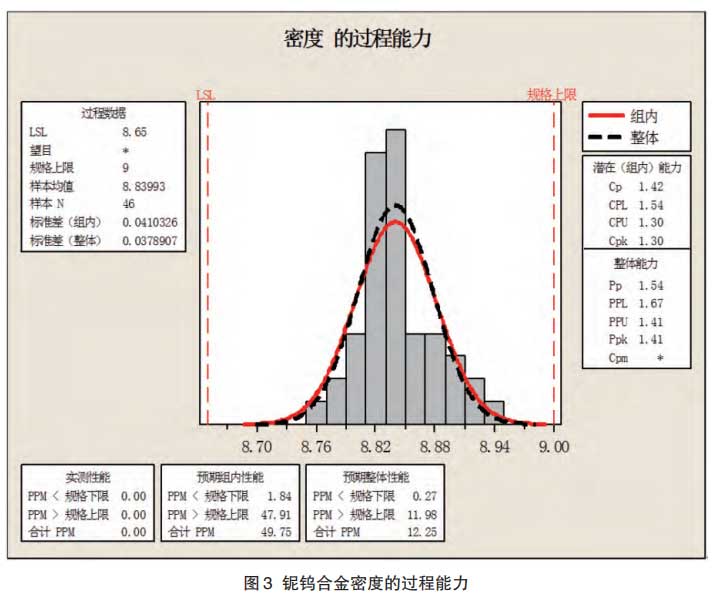

Through statistical analysis of previous data, the density of niobium tungsten alloy can meet and stabilize in the range of ≤9.0g/cm3, and can be stably controlled in the range of 8.65 ~ 9.0g/cm3 (the process capability of density is shown in Figure 3). Therefore, the "Specification" stipulates that the density of niobium tungsten alloy rods is 8.65 ~ 9.0g • cm-3.

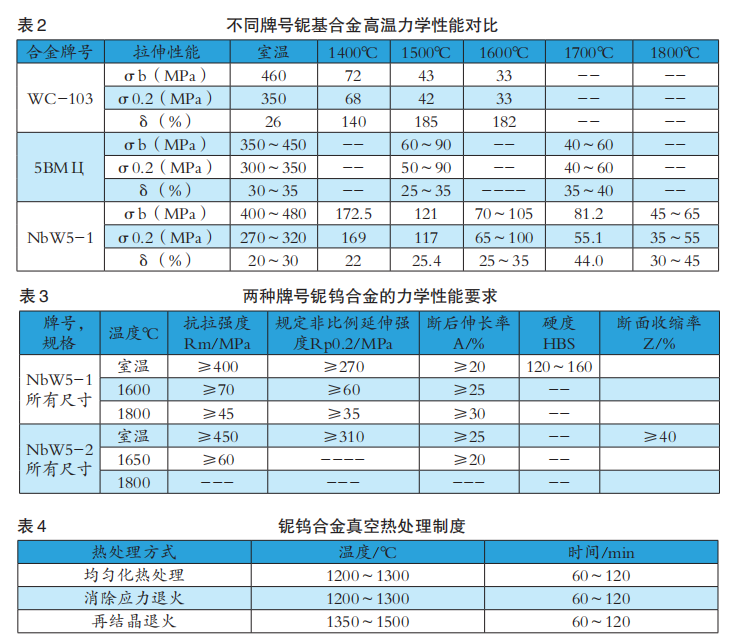

3. Mechanical properties

The mechanical properties of alloys are the focus of aerospace engine designers when selecting materials. The mechanical properties of alloys at room temperature determine the machinability of alloys, and the high-temperature mechanical properties determine the working performance and life of aerospace engines. Before niobium tungsten alloy, domestic aerospace design units generally used WC-103 alloy, whose working temperature was set at 1300℃. As an alternative material to WC-103 alloy, the working temperature of niobium tungsten alloy is set at 1600℃, and its high-temperature mechanical properties far exceed WC103 alloy and the former Soviet Union's 5BMЦ alloy [7]. When the "Specification" was formulated, the mechanical properties of the two grades of niobium tungsten alloy at room temperature, 1600℃ and above 1600℃ were strictly regulated based on the large amount of test data accumulated by the two production units.

4. Heat treatment system

Niobium tungsten alloy ingots are extruded, forged and processed into finished bars. In the middle, they need to undergo multiple heat treatments to eliminate processing stress, reduce the hardness of the alloy intermediate material, refine the alloy grains and homogenize the alloy structure. Therefore, the heat treatment process has an important influence on the mechanical properties and macrostructure of the final alloy bar. Therefore, the "Specification" stipulates the heat treatment system of niobium tungsten alloy. It should be noted that since niobium-based alloys are easily oxidized, all heat treatments must be carried out under vacuum [8,9].

Principles for the formulation of the "Specification"

The "Specification" stipulates the requirements, quality assurance specifications, delivery preparation, etc. of niobium tungsten alloy (Nb521) in accordance with the requirements of GJB0.1 "Guidelines for the Preparation of Military Standard Documents Part 1: Provisions for the Preparation of Military Standards and Guiding Technical Documents" and GJB0.2 "Guidelines for the Preparation of Military Standard Documents Part 2: Provisions for the Preparation of Military Specifications". The specific content is determined in accordance with the following principles [10,11].

1. The principle of fully meeting market requirements

When formulating the "Specification", the use requirements of niobium tungsten alloy and niobium tungsten alloy bar products in multiple technical agreements of 5 aerospace user units were fully analyzed, and unified standard terms were formed after summary and synthesis, and the opinions of existing and potential user units were fully solicited. Therefore, it can fully meet market demand and represent the requirements of aerospace customers for the quality of military products.

2. Principles guiding production

With the gradual maturity of production technology and the continuous development of aerospace technology, there will be more and more engine models using niobium tungsten alloy bars. In the absence of standards for similar products at home and abroad, the formulation of the "Specification" has an important guiding and promoting role in standardizing the production of niobium tungsten alloy bars and improving the consistency and stability of product quality.

3. Principles of applicability and advancement

When formulating the "Specification", the opinions of user units and the relevant requirements of national military standards for similar products were widely solicited, and the development needs of my country's aerospace industry, the current status of the development of niobium tungsten alloy bars and subsequent trends were comprehensively considered, so that this standard reflects advancement on the basis of applicability.

Conclusion

With the continuous improvement of my country's comprehensive national strength, the aerospace industry will be greatly developed, and the application of niobium tungsten alloys is bound to continue to grow. Under such circumstances, the formulation and implementation of the "Specification for Niobium Tungsten Alloy Bars for Aerospace" will play an important role in the standardized production, technological progress and quality assurance of coating products in the future.

About Stardust Technology

Stardust Technology (Guangdong) Co., Ltd. is a national high-tech enterprise specializing in the research and development, production and sales of high-end spherical powder materials in the fields of 3D printing, powder metallurgy, surface engineering, etc. The company insists on taking RF plasma spheroidization powder making technology as the core, providing internationally advanced powder products and application solutions.

The company's main products include high-end rare refractory metals such as tungsten, molybdenum, tantalum, niobium, vanadium, rhenium, chromium and their alloys, compound spherical powders, and also provides RF plasma spheroidization, plasma rotating electrode atomization, 3D printing, hot isostatic pressing, injection molding, powder metallurgy and other technical services. Stardust Technology not only provides high-quality powders, but also brings integrated molding solutions for additive manufacturing, helping innovative intelligent manufacturing and leading future technology!

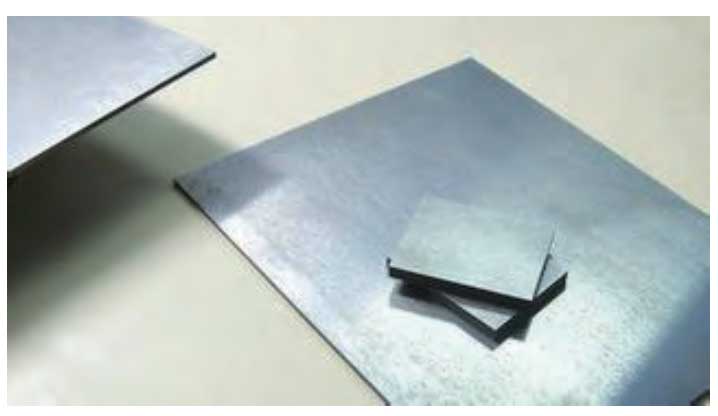

The following is the spherical Nb521 alloy powder produced by Stardust Technology using RF plasma spheroidization technology.

https://www.stardustpowder.com/niobium-tungsten-alloy15-53mm

Welcome to inquire

Article source: (C) 1994-2023 China Academic Journal Electronic Publishing House. All rights reserved. http://www.cnki.net