From November 19th to 22nd, local time, Formnext 2024-Frankfurt International Precision Forming and 3D Printing Manufacturing Exhibition was held in Frankfurt Exhibition Center, Germany. Stardust Technology, as the only exhibitor of refractory metal powder for additive manufacturing, made a shining appearance with leading partners around the world and stepped onto the international stage!

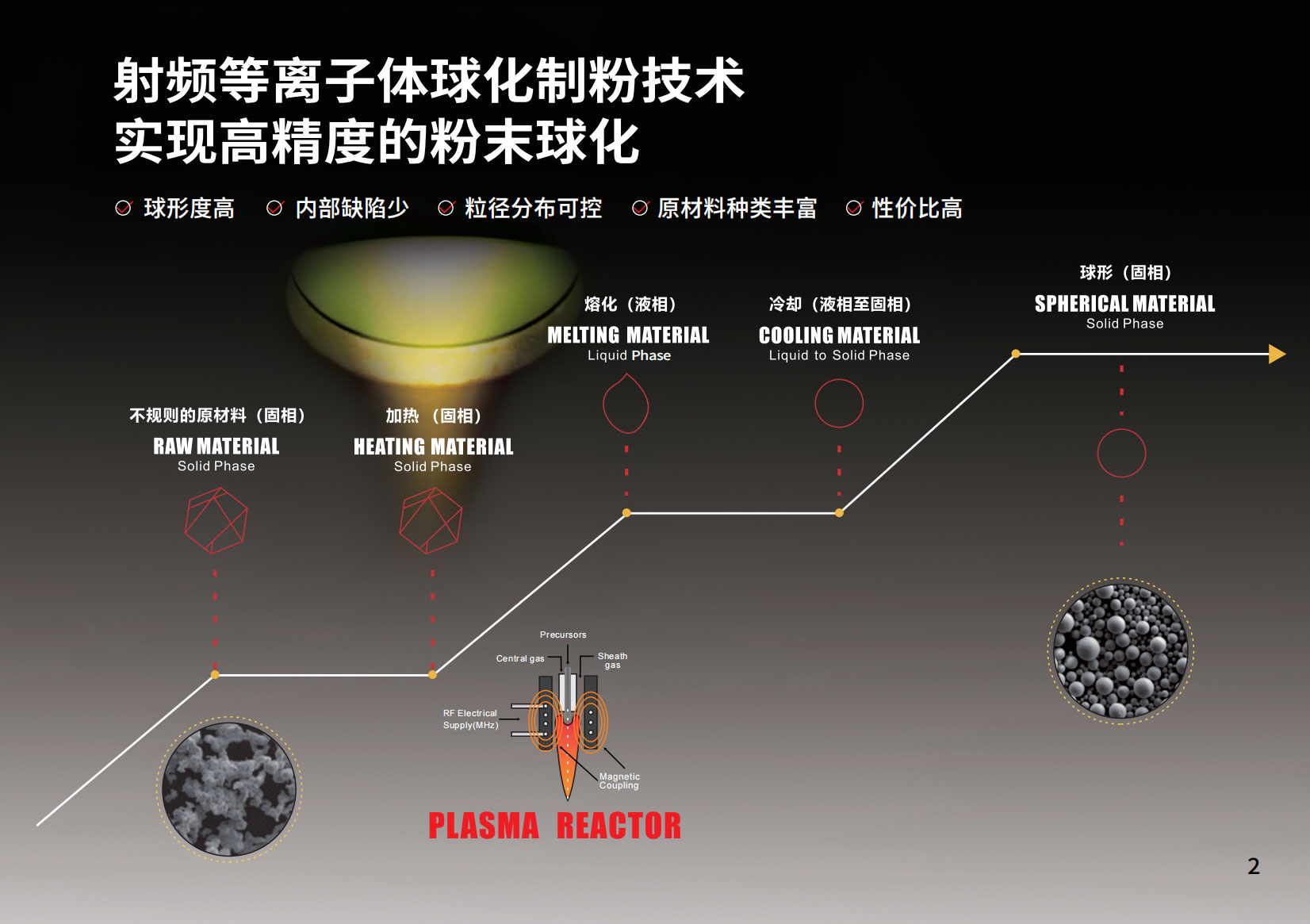

In this top event that brings together the world's top companies and outstanding scholars, Stardust Technology launched a series of breakthrough and innovative products and application solutions. It has been committed to focusing on the preparation and production of high-end rare refractory metal spherical powders with RF plasma spheroidization powder making technology as the core. During the exhibition, the main products were launched, including rare refractory spherical metal single powders such as tungsten, molybdenum, tantalum, niobium, titanium, zirconium, vanadium, chromium, rhenium, hafnium, and their spherical alloy powders and spherical refractory high entropy alloy powders. At temperatures as high as 8000℃, the powders produced by RF plasma spheroidization equipment have the characteristics of high purity and low oxygen, high sphericity, few internal defects, controllable particle size distribution, and excellent flowability, covering aerospace, national defense, military industry, medical equipment, electronic information, nuclear industry and other fields.

Stardust Technology's exploration and innovation in cutting-edge technology can provide customers with internationally advanced and complete integrated solutions for powder preparation and modification, and then to application. At present, the technology of Selective Laser Melting (SLM) is mainly used for powder printing process development, which includes the whole process from design, printing to post-processing, and can help customers obtain the best materials and technical support at different manufacturing stages. Stardust Technology provides customers with customized 3D printing design solutions to ensure that the material performance during the printing process is maximized and cost reduction and efficiency improvement are achieved. It also provides a complete set of post-processing technologies, covering heat treatment, surface treatment, etc., to ensure that the printed parts meet the performance standards of the final application.

At the exhibition, the spherical tantalum powder independently developed by Stardust Technology is widely used in the biomedical field due to its excellent biocompatibility and bone ingrowth characteristics. The artificial hip joints, intervertebral fusion devices and micro-reaction channel prints formed by SLM technology have also won the deep attention and active cooperation intentions of many overseas customers.

The 2024 Formnext exhibition has come to a successful conclusion, but our journey of cooperation and innovation has just begun! This exhibition provides a platform for in-depth exchanges with global industry leaders, technical experts and potential partners, and we have also gained valuable market feedback and technical inspiration from it, which has brought us practical business results and development opportunities. In the future, Stardust Technology will continue to provide customers with technical support and services such as powder customization, process exploration, printing services, post-processing, and structural improvement, and promote the development of 3D printing and additive manufacturing technology through continuous innovation.

IPv6 network supported

IPv6 network supported