W-Ni high-density tungsten alloys, including W-Ni-Cu and W-Ni-Fe alloys, are the main material systems of tungsten alloys. They have a series of characteristics such as high density, high strength and hardness, good electrical and thermal conductivity, low thermal expansion coefficient, excellent corrosion resistance, excellent machinability and weldability, and are therefore widely used in the fields of national defense industry, military equipment, aerospace, and electronic information [1-2]. At present, the processing and preparation method of tungsten alloys is mainly powder metallurgy liquid phase sintering, but it has limitations such as easy collapse and deformation, and it is difficult to manufacture complex structural parts, and subsequent mechanical processing is usually required [3]. For the manufacture of complex structural parts of tungsten alloys, people have developed powder injection molding technology, but it also has shortcomings such as cumbersome process, long cycle, and the need for degreasing process, which makes it difficult to meet the requirements of high-density integrated direct manufacturing of complex structural parts of tungsten alloys [4-5]. Laser powder bed fusion (LPBF) additive manufacturing technology is based on the principle of melting metal powder point by point and line by line with a high-energy laser beam and forming it layer by layer. It has obvious advantages in the high-precision direct manufacturing of complex metal structures. It has been widely studied and applied in the manufacturing of complex structures of materials such as titanium alloys, aluminum alloys, and high-temperature alloys, showing excellent mechanical properties and great application potential [6-9]. At present, the research on W-Ni laser powder bed fusion additive manufacturing is still in its early stages. Zhang et al. [10] used mixed W-Ni powders and laser powder bed fusion additive manufacturing technology to prepare tungsten-nickel alloy samples with Ni contents of 10%, 20%, and 30%. The effect of Ni content on the microstructure of tungsten-nickel alloy was discussed. The results showed that with the increase of Ni content, the microstructure morphology was strip, dendrite, and honeycomb structure. Yan Anru et al. [11] studied the laser powder bed fusion forming process and thermophysical properties of 80W-5Ni-15Cu and obtained a sample with a relative density of 94.5%. Wang et al. [12] studied the laser powder bed fusion forming process parameters of 80W-10Ni-10Cu and characterized and analyzed its microstructure and microhardness. Zhang et al. [13] prepared 90W-7.5Ni-2.5Cu using laser powder bed fusion technology and analyzed its forming process parameters and microstructure. Li et al. [14] and Iveković et al. [15] studied the laser powder bed fusion process parameters, microstructure and mechanical properties of 90W-7Ni-3Fe. The relative density of the prepared samples was better than 99%, and the mechanical properties were comparable to those of powder sintered samples. In addition, Chen et al. [16] studied the microstructure and mechanical properties of W-6Ni-2Fe-2Co, W-12Ni-4Fe-4Co and 70W-18Ni-6Fe-6Co formed by laser powder bed melting, and obtained a W-Ni-Fe-Co sample with a relative density of 96.1% and a maximum tensile strength of 1198 MPa. In summary, from the above-mentioned related research literature, laser powder bed melting additive manufacturing technology can realize the preparation of W-Ni high-density alloy samples with good relative density and mechanical properties. However, the mass fraction of W in the above-mentioned W-Ni high-density alloy is only 90% at most, which reduces the density of tungsten alloy and limits the application scenarios of tungsten alloy to a certain extent.

Therefore, this study uses a mixed powder of tungsten and nickel with a mass fraction of 93:7 to explore the laser powder bed melting additive manufacturing of tungsten-nickel alloys with high tungsten content, and studies the densification, microstructure and microhardness of tungsten-nickel alloys, providing technical support for the subsequent direct manufacturing of high-density tungsten-nickel alloy complex structural parts with high tungsten content.

1 Experiment

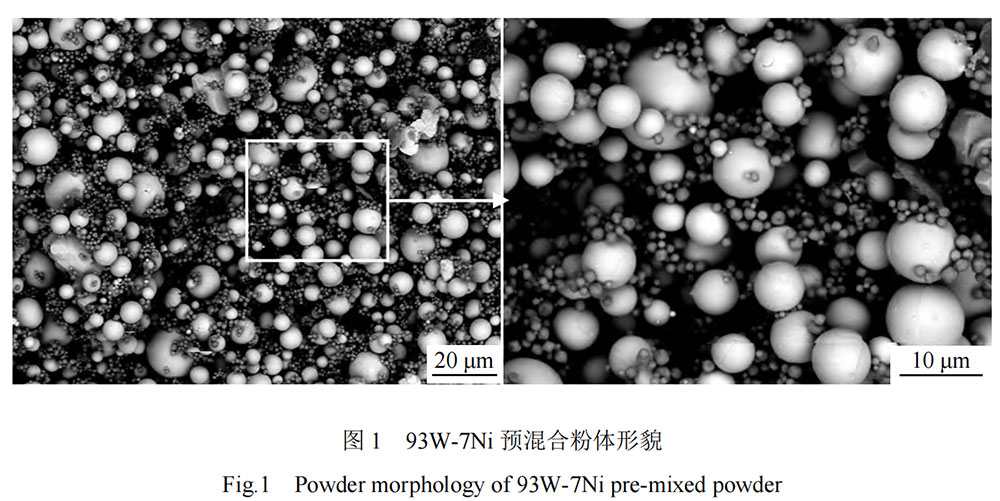

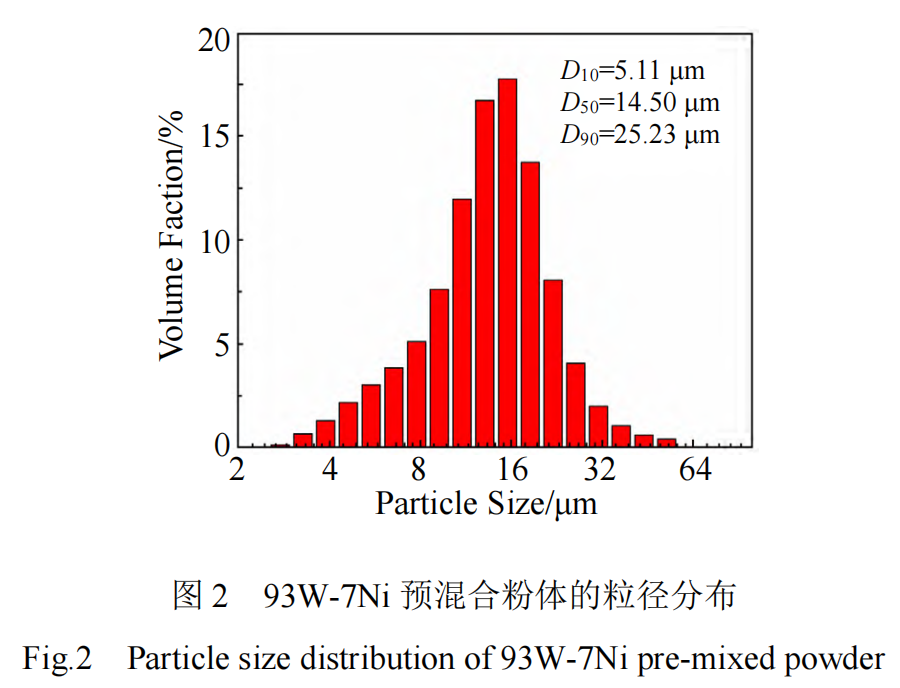

In this study, spherical tungsten powder and submicron spherical nickel powder particles are mixed in a mass fraction of 93:7 to obtain a tungsten-nickel premixed powder material. The powder morphology is shown in Figure 1. It can be seen from the figure that although the fine nickel powder particles are adsorbed to each other, they are still relatively evenly distributed between the tungsten particles. At the same time, some nickel particles are adsorbed on the surface of the tungsten particles, which can ensure that there are a certain amount of nickel particles around the tungsten particles, and there is no obvious separation area between tungsten particles and nickel particles. Figure 2 further gives the particle size distribution information of the tungsten-nickel premixed powder, specifically D10=5.11 μm, D50=14.50 μm, D90=25.23 μm, and the powder particle size meets the requirements of laser powder bed melting additive manufacturing.

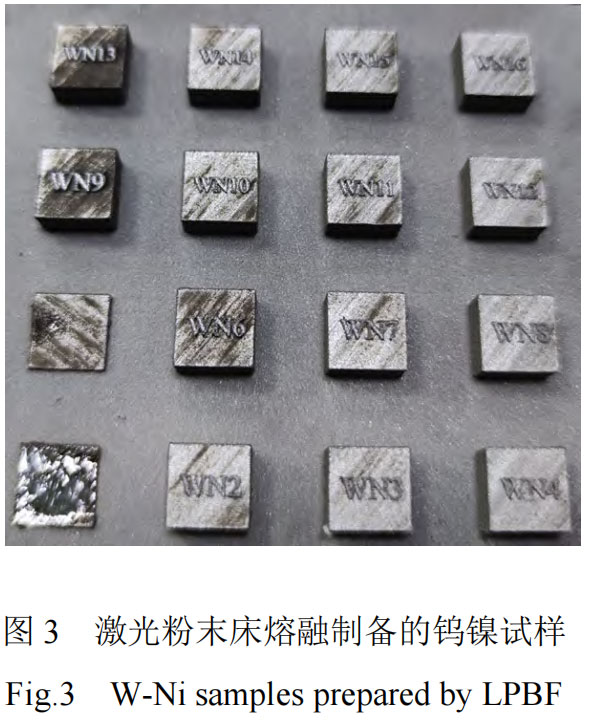

The bulk forming experiment of 93W-7Ni alloy was carried out using the LM-150 equipment. During the experiment, the laser power used was 200, 250, 300 and 350 W; the scanning speed was 200, 300, 400 and 500 mm/s; the filling spacing and powder layer thickness were fixed at 0.08 and 0.03 mm, respectively. In addition, during the bulk forming process, a scanning strategy of 67° interlayer rotation was adopted, and in order to ensure the good combination of the substrate and the starting layer and avoid warping and cracking, the preheating temperature of the stainless steel substrate was always kept at 80 °C during the entire forming process. Finally, based on the above forming conditions, a tungsten-nickel alloy block sample with a size of 10 mm×10 mm×5 mm was successfully prepared, as shown in Figure 3. It can be seen from the figure that the tungsten-nickel premixed powder has good formability, and the prepared tungsten-nickel alloy block has good surface and shape integrity. In order to analyze the internal defects and relative density of the tungsten-nickel alloy sample, the sample was cut from the substrate using an electric spark wire cutting machine and cleaned and dried with ethanol. After that, according to the standard metallographic process, the cross section of the sample was polished using 240#, 400#, 600#, 800#, 1000#, and 1200# silicon carbide sandpaper in sequence, and then polished to obtain a metallographic sample that meets the requirements of optical microscope observation. After that, the cross-sectional morphology of the tungsten-nickel alloy sample was characterized using a Nikon MA200 metallographic microscope, and at least 10 areas were characterized for each sample. Finally, Image pro plus software was used to measure the internal defects of the samples and then evaluate the relative density of the samples. The specific process includes: (1) using Image pro plus software to binarize the cross-sectional metallographic images of 10 areas of each sample; (2) based on Image pro plus software, the defect areas in the metallographic images were identified by reasonable grayscale values and the defect area ratio was measured; (3) the average defect area ratio was calculated based on the defect area ratio of all metallographic images, which was used as the final internal defect area ratio of the sample under the process parameters; at the same time, the maximum area and average area of the internal defects of the tungsten-nickel alloy samples were further analyzed and estimated, and the defect morphology was measured by the aspect ratio. The smaller the aspect ratio, the more the defect morphology tends to be circular.

In order to analyze the microstructure of the tungsten-nickel alloy sample, the polished sample was subjected to metallographic etching. The etching solution used was a mixed solution of potassium hydroxide, potassium ferrocyanide and water in a ratio of 1:1:10, and the etching time was about 30 s. Afterwards, the microstructure of the tungsten-nickel alloy sample was characterized by a VEGA 3 XMU scanning electron microscope (SEM); at the same time, the elemental composition and distribution of the sample were characterized by an energy dispersive spectrometer (EDS). In order to analyze the phase composition of the mixed powder and the formed sample, the phase composition of the tungsten-nickel premixed powder and the tungsten-nickel alloy sample was analyzed by a Bruker D8 Advance X-ray diffractometer. During the test, a Cu target material was used, with an angle range of 30°~90°, a working voltage of 40 kV, and a working current of 40 mA.

The microhardness of the tungsten-nickel alloy sample was measured by an HVS-1000 microhardness tester, with a loading load of 500 g and a loading time of 15 s. At least 10 points were measured for each sample and the average value was calculated as the microhardness of the sample.

2 Results and discussion

2.1 Densification of tungsten-nickel alloy specimens by laser powder bed melting

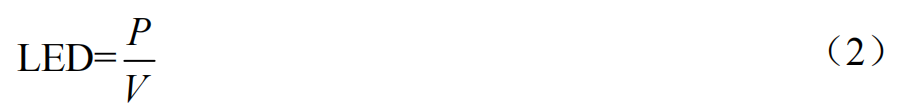

Controlling internal defects of formed parts and improving the relative density of formed specimens are the first issues to be studied in the process of laser powder bed melting, and the formation of defects is mainly affected by process parameters. In order to study the comprehensive effect of laser power and scanning speed in the process of laser powder bed melting, the linear energy density (LED) is defined, and the expression is as follows [17]:

Where P is the laser power, W, V is the scanning speed, mm/s.

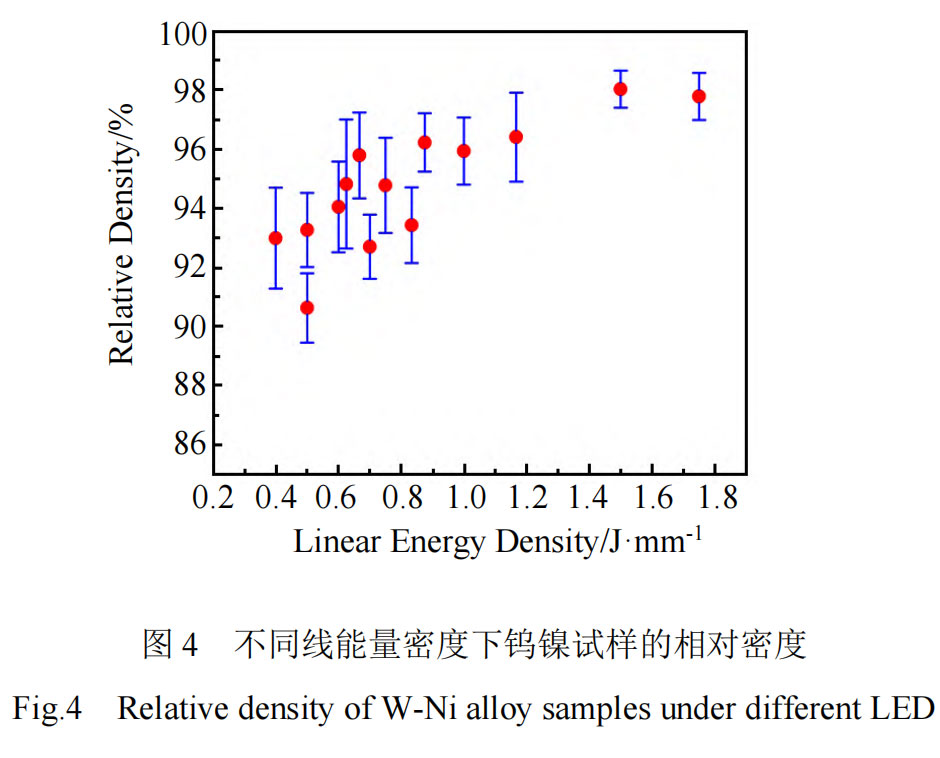

Figure 4 shows the relationship between the relative density and linear energy density of the tungsten-nickel alloy specimen obtained by the imaging method. It can be observed from the figure that the relative density of the tungsten-nickel alloy specimen generally increases first and then slightly decreases with the increase of linear energy density. The relative density of the tungsten-nickel alloy specimens prepared by the linear energy density used in this study is higher than 90%, and the relative density of the prepared tungsten-nickel alloy specimens is the largest, reaching 98.04%, when the linear energy density of 1.5 J/mm is used in the forming process, that is, the laser power is 300 W and the scanning speed is 200 mm/s.

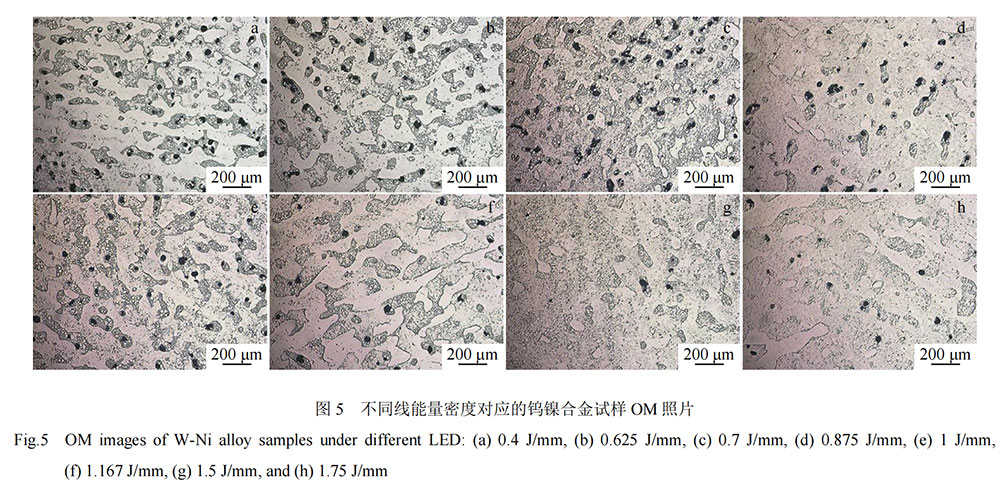

In order to further discuss the internal defect characteristics and formation mechanism of the tungsten-nickel alloy specimens prepared by laser powder bed melting, Figure 5 shows the cross-sectional microstructure of the tungsten-nickel alloy specimens corresponding to different linear energy densities. It can be directly observed from the figure that the internal defects of all the prepared tungsten-nickel alloy specimens are mainly irregular pore defects, and there are no obvious visible microcrack defects; and when a relatively low laser energy density is used, there are a large number of irregular pores inside the tungsten-nickel alloy specimens; with the increase of the linear energy density, the irregular pores gradually decrease, and when the linear energy density is 1.5 J/mm, their number is significantly reduced, and the pore size is also reduced.

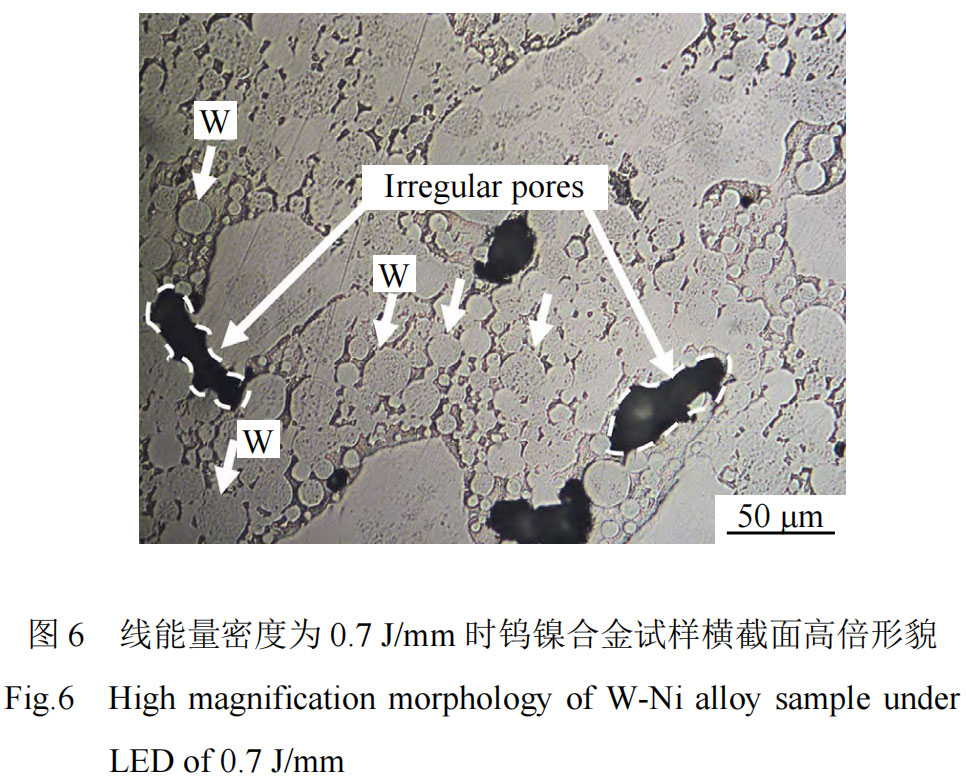

In order to further analyze the defect types and formation mechanisms during the laser powder bed melting process of tungsten-nickel alloy, Figure 6 shows the high-magnification morphology of the cross section of the tungsten-nickel alloy sample prepared with a linear energy density of 0.7 J/mm. It can be seen from the figure that the forming mechanism of the laser powder bed melting tungsten-nickel alloy sample is mainly liquid phase sintering, that is, a large number of high-melting point tungsten particles (as shown by the small arrows in the figure) are not melted, while the low-melting point nickel is melted to form a liquid phase filling between the solid phase tungsten particles. This forming mechanism is similar to the traditional powder metallurgy of tungsten alloy.

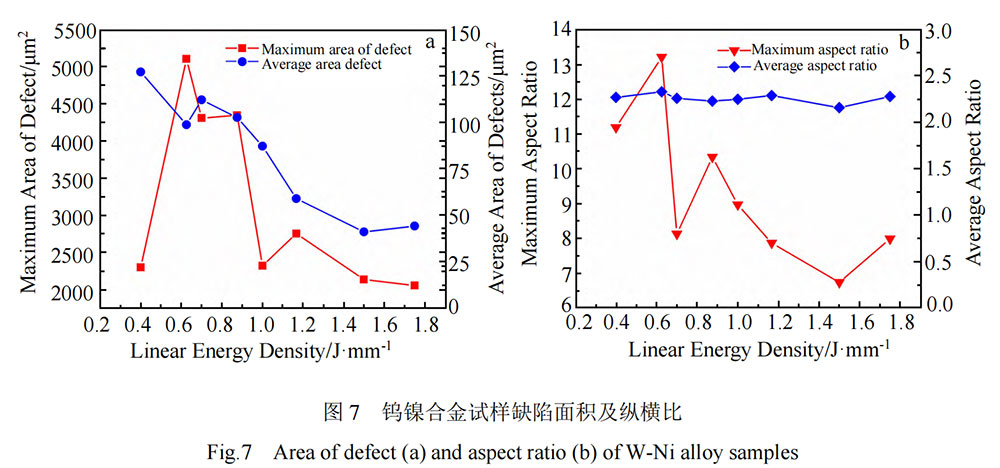

Obvious irregular pore defects can be found in Figure 6 (as shown by the dotted line in the figure). This is because when the linear energy density of 0.7 J/mm is used, the corresponding laser power is 350 W and the scanning speed is 500 mm/s. Under this forming process condition, the tungsten-nickel powder material per unit length is irradiated by the laser for a relatively short time. When the mixed powder is irradiated by the laser, the low-melting-point nickel powder particles melt rapidly to form a liquid phase, which begins to flow and fill along the boundaries of the tungsten particles under the action of capillary force. Due to the short laser residence time per unit length, the liquid phase solidifies before fully filling the gaps between the tungsten particles; at the same time, during the flow and spreading process, it will form a large flow resistance due to the friction between the liquid phase and the solid particles, which will eventually lead to the formation of irregular underfilled pore defects. When the linear energy density is 0.7 J/mm, the estimated maximum area of the internal defects of the tungsten-nickel alloy specimen is 4309.67 μm2, the average defect area is 112.21 μm2, the maximum aspect ratio is 8.13, and the average aspect ratio is 2.26. When a lower linear energy density is used, the average area and aspect ratio of the internal irregular defects of the tungsten-nickel alloy specimen increase, as shown in Figure 7.

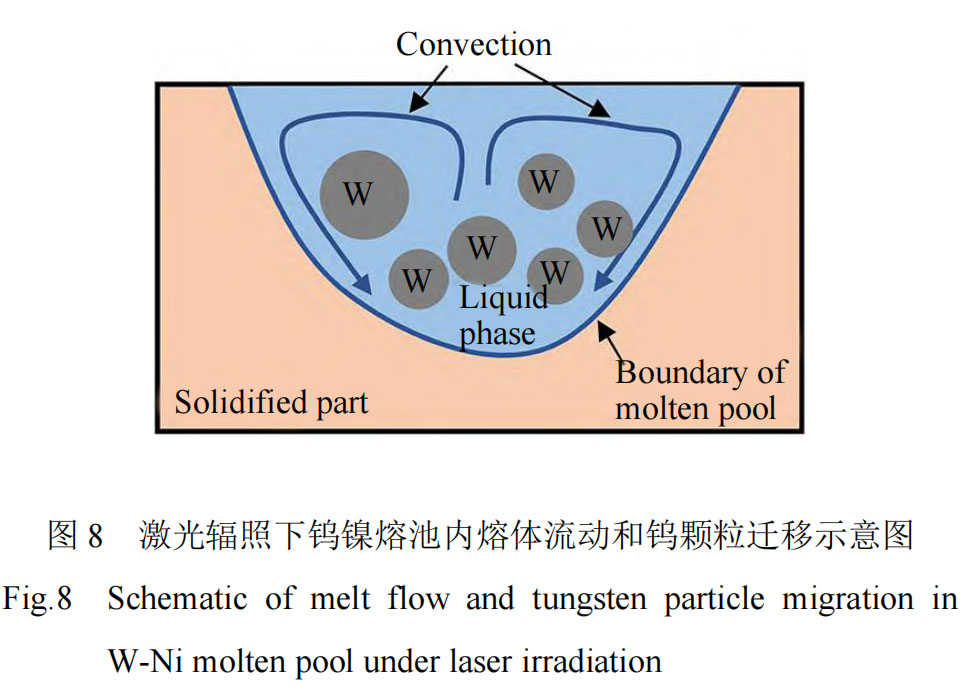

With the continuous increase of linear energy density, the energy absorbed by tungsten-nickel powder increases. During the laser irradiation of tungsten-nickel powder, the temperature of the melt inside the micro-melting pool formed by the melting of the powder increases rapidly, and more low-melting-point nickel powder melts, which significantly increases the amount of liquid phase. At this time, the gaps between tungsten particles can be filled more completely; at the same time, due to the rapid increase in temperature inside the micro-melting pool, the viscosity of the liquid phase decreases, and its flow filling speed is significantly improved, which can more fully fill the gaps between particles in a short time; in addition, under high energy input conditions, stronger convection phenomena will be formed between the center and edge of the micro-melting pool, which will promote the migration and rearrangement of tungsten particles in the molten pool, accelerate the flow filling of the liquid phase, and reduce the formation of pore defects, as shown in Figure 8.

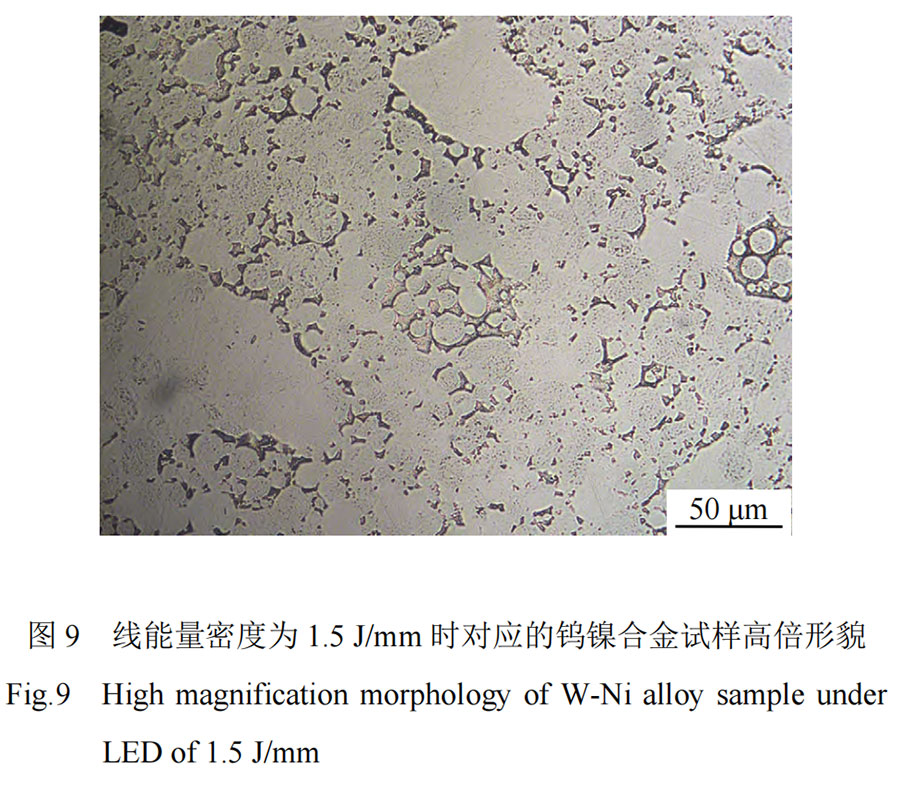

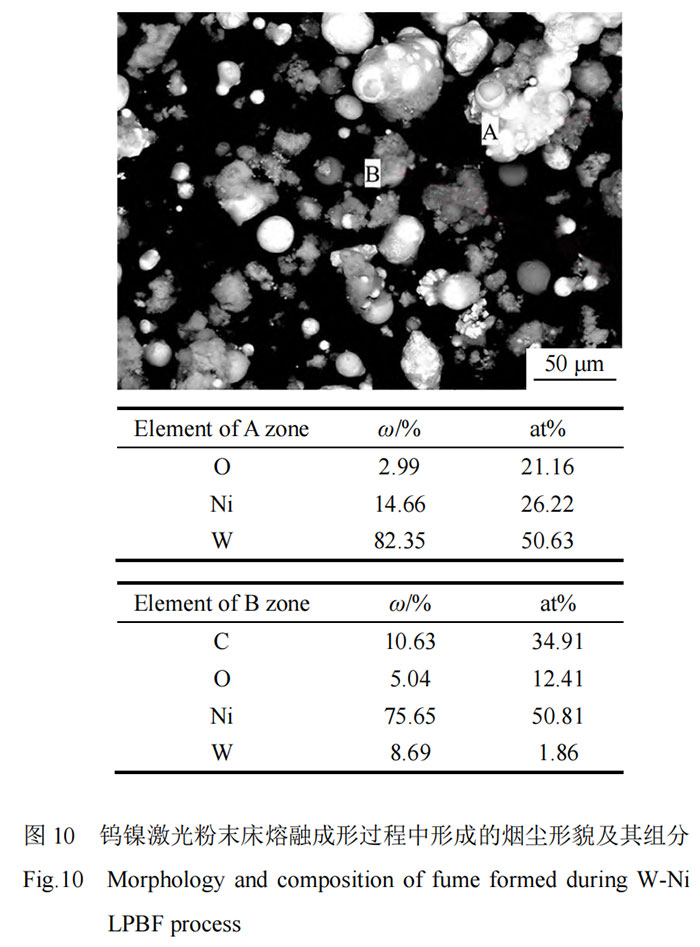

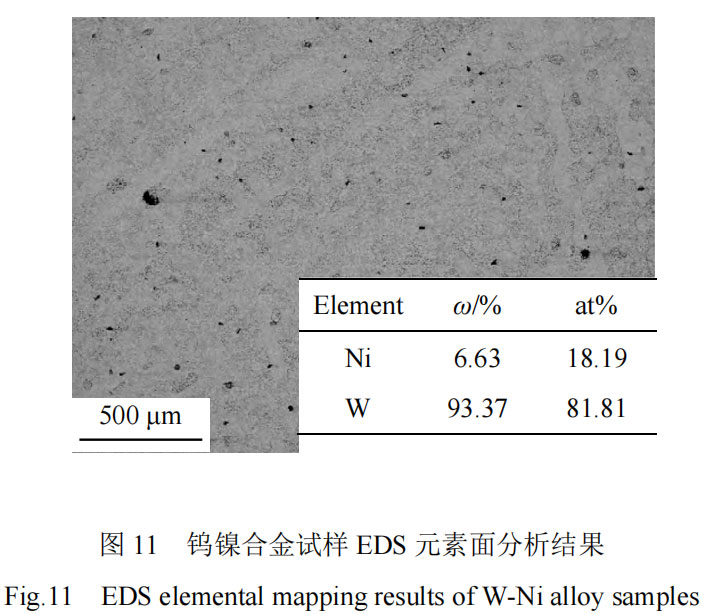

Figure 9 is a high-magnification morphology of a tungsten-nickel alloy sample at 1.5 J/mm. It can be seen from the figure that the tungsten particles are dispersed and arranged more densely, and the liquid phase formed by the low-melting-point nickel almost completely fills the gaps between tungsten particles, which significantly reduces the pore defects inside the sample. According to Figure 7, the maximum defect area of the tungsten-nickel alloy sample prepared under this linear energy density is estimated to be 2135.48 μm2, and the average defect area is 41.05 μm2; the maximum aspect ratio is 6.74, and the average aspect ratio is 2.15. Compared with the tungsten-nickel alloy sample prepared at a low linear energy density, its internal defects have been significantly reduced. Further increasing the linear energy density to 1.75 J/mm, corresponding to a laser power of 350 W and a scanning speed of 200 mm/s, the energy absorbed by the tungsten-nickel powder is further increased, and the melt fluctuation in the micro-melting pool under laser irradiation is intensified, which may involve more argon gas and cause more pores to remain; at the same time, higher heat input may cause the evaporation of metallic nickel, resulting in a decrease in the amount of liquid phase, leading to an increase in the number of irregular pores. Figure 10 shows the SEM morphology and components of the smoke formed during the forming process collected after the experiment. From the figure, a large number of floccules can be seen, and its main components include W and Ni, indicating that some elements are lost during the forming process. Figure 11 further shows the EDS surface scanning element analysis results of the cross-section of the tungsten-nickel alloy sample. It can be seen that the Ni content is slightly reduced, but not completely lost.

2.2 Phase and microstructure of tungsten-nickel alloy sample prepared by laser powder bed melting

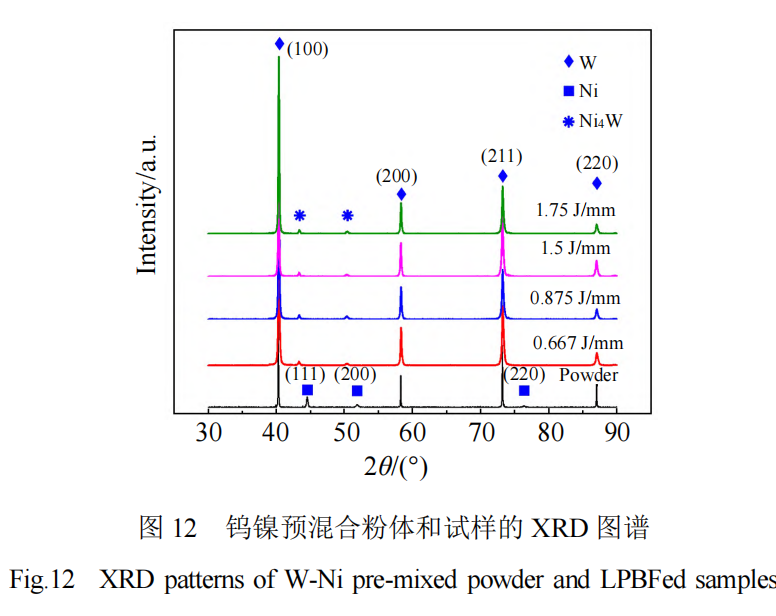

Figure 12 shows the XRD spectrum of the tungsten-nickel premixed powder and the tungsten-nickel alloy block sample prepared by laser powder bed melting. It can be seen from the figure that there are two phases of W and Ni in the tungsten-nickel premixed powder. When the tungsten-nickel premixed powder is irradiated by laser, the Ni powder is completely melted. There is no separate Ni peak in the tungsten-nickel alloy block sample, but a Ni4W intermetallic compound is formed. This is formed by the reaction of part of the tungsten dissolving into the nickel matrix. This is consistent with the results of W-Ni samples prepared by laser additive manufacturing technology [10,18].

In addition, by comparing the XRD spectra of the tungsten-nickel block samples prepared by laser powder bed melting at different line energy densities, the diffraction peak positionThere is no obvious change. At this time, the phases of all bulk samples are composed of W single phase and Ni4W intermetallic compound phase, which indicates that the phase composition of the tungsten-nickel alloy samples prepared by laser powder bed melting is not significantly affected by the forming process parameters, and the high energy input does not cause a large loss of Ni element.

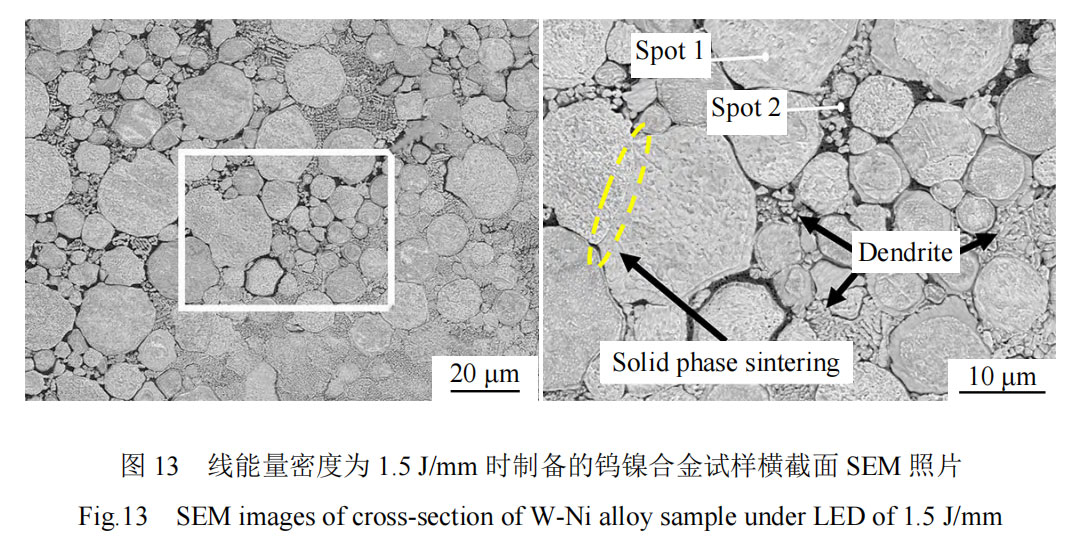

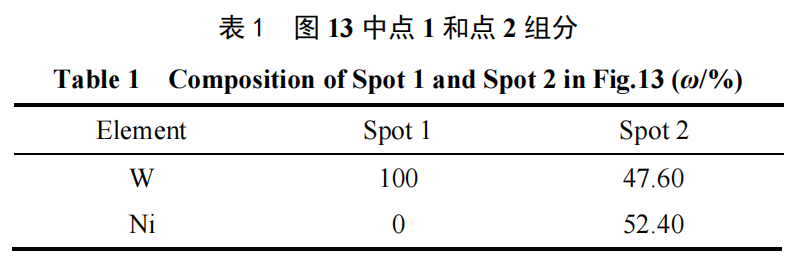

Figure 13 shows the cross-sectional SEM photos of the tungsten-nickel alloy samples corresponding to the linear energy density of 1.5 J/mm. It can be directly observed from the figure that there are three microstructural morphologies of the tungsten-nickel alloy samples formed by laser powder bed melting, namely solid tungsten particles, matrix phase and dendrites. Table 1 shows the composition results of points 1 and 2 in Figure 13. It can be confirmed from the table that the tungsten particles have not been completely melted and have always maintained a single phase state. At the same time, in addition to the liquid phase formed by the melting of Ni, a large amount of W is dissolved in the black matrix phase. This is because although the solubility of Ni in W is extremely low, W has a high solubility in Ni. Studies have shown that at 1500 °C, the solubility of W in Ni can reach 45%[19]. Therefore, during the forming process, a large amount of W is dissolved into the Ni matrix phase to form a solid solution.

Figure 13 shows the cross-sectional SEM photos of the tungsten-nickel alloy samples corresponding to the linear energy density of 1.5 J/mm. It can be directly observed from the figure that there are three microstructural morphologies of the tungsten-nickel alloy samples formed by laser powder bed melting, namely solid tungsten particles, matrix phase and dendrites. Table 1 shows the composition results of points 1 and 2 in Figure 13. It can be confirmed from the table that the tungsten particles have not been completely melted and have always maintained a single phase state. At the same time, in addition to the liquid phase formed by the melting of Ni, a large amount of W is dissolved in the black matrix phase. This is because although the solubility of Ni in W is extremely low, W has a high solubility in Ni. Studies have shown that at 1500 °C, the solubility of W in Ni can reach 45%[19]. Therefore, during the forming process, a large amount of W is dissolved into the Ni matrix phase to form a solid solution.

At the same time, unlike the microstructure of powder sintered tungsten alloy, a large number of fine dendritic/granular tungsten grains are also formed in the tungsten-nickel alloy sample formed by laser powder bed melting. Under high-energy laser irradiation, the tungsten-nickel mixed powder absorbs a large amount of heat and quickly melts to form a micro-molten pool. At this time, the temperature inside the melt rises rapidly, far higher than the melting point of tungsten. At this time, while the low-melting-point nickel powder is completely melted instantaneously, the tungsten particles are also partially melted during the rapid melting/solidification process, and the circular tungsten particle outline is transformed into a polygonal outline, as shown in Figure 13, indicating that tungsten is partially melted and dissolved, and fine tungsten dendrites are formed during the rapid solidification process. At the same time, due to the flow of the liquid phase melt in the molten pool, some dendrite structures are broken to form fine granular tungsten grains.

In addition, it is worth noting that from Figure 13, a large number of tungsten grains can be found to be in direct surface contact, forming sintering necks during the powder sintering process, indicating that under high-energy laser irradiation, the tungsten powder particles produce atomic surface diffusion and volume diffusion during the flow rearrangement contact process, the original W particle interface migrates, and some W particles merge to form polygonal W grains, which also accelerates the densification rate of the tungsten-nickel alloy sample to a certain extent, indicating that there is also a solid phase sintering process in the process of laser powder bed melting forming of tungsten-nickel alloy samples, which may be related to the higher tungsten content. The high tungsten content increases the possibility of direct contact between unmelted tungsten particles during multiple thermal cycles.

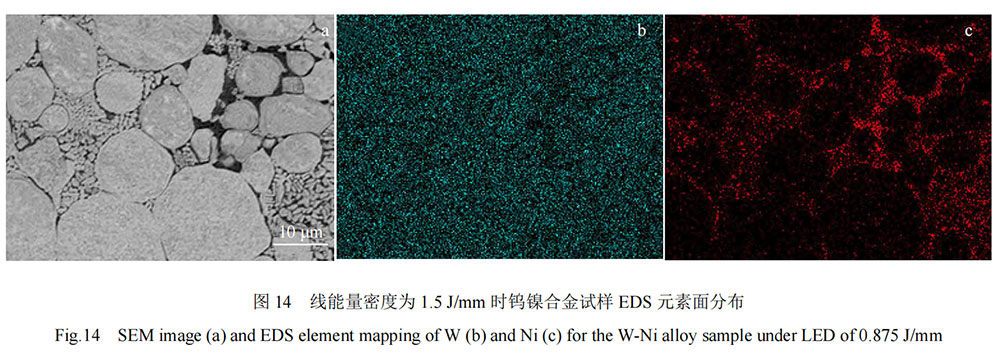

Figure 14 shows the EDS surface distribution results of the tungsten-nickel alloy sample when the linear energy density is 1.5 J/mm. From the figure, it can be found that the W element is distributed more evenly in the tungsten-nickel alloy sample formed by laser powder bed melting, and there is almost no Ni element inside the tungsten particles; while the Ni element is mainly concentrated in the matrix phase, which is consistent with the previous point analysis results.

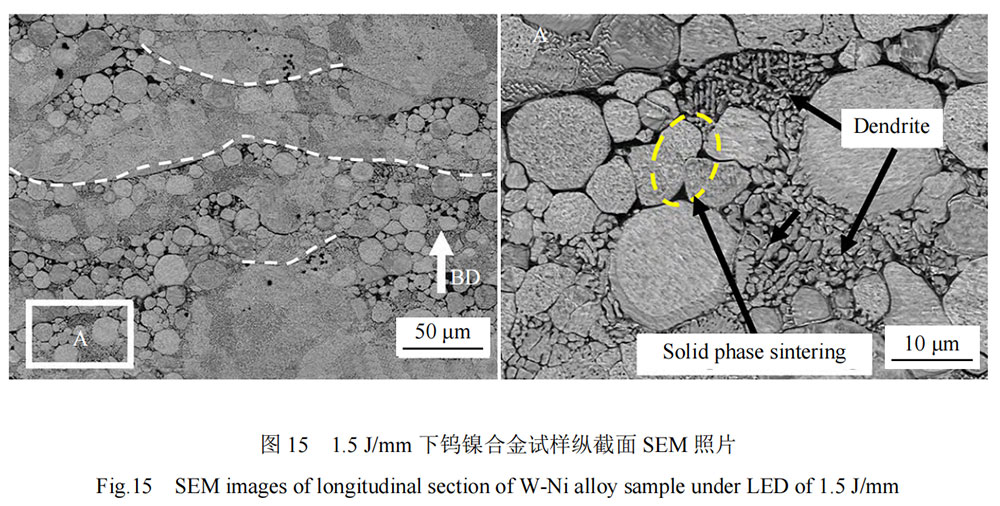

Figure 15 further shows the longitudinal section microstructure morphology of the W-Ni sample formed by laser powder bed melting at 1.5 J/mm. It can be seen from the figure that the microstructure of the longitudinal section of the tungsten-nickel alloy sample has obvious stratification characteristics, as shown by the white dotted arc in the figure, indicating the forming characteristics of the interlayer thermal cycle of the laser powder bed melting. In the longitudinal section, it can be found that the tungsten particles do not maintain the original circular contour of the tungsten particles, but all show different degrees of polygonal contours. A large amount of tungsten undergoes rapid melting/solidification under laser irradiation to form fine tungsten grains; similarly, obvious surface contact occurs during the flow rearrangement of tungsten grains, and polygonal coarsened tungsten grains are synthesized during the atomic mutual diffusion process.

Figure 15 further shows the longitudinal section microstructure morphology of the W-Ni sample formed by laser powder bed melting at 1.5 J/mm. It can be seen from the figure that the microstructure of the longitudinal section of the tungsten-nickel alloy sample has obvious stratification characteristics, as shown by the white dotted arc in the figure, indicating the forming characteristics of the interlayer thermal cycle of the laser powder bed melting. In the longitudinal section, it can be found that the tungsten particles do not maintain the original circular contour of the tungsten particles, but all show different degrees of polygonal contours. A large amount of tungsten undergoes rapid melting/solidification under laser irradiation to form fine tungsten grains; similarly, obvious surface contact occurs during the flow rearrangement of tungsten grains, and polygonal coarsened tungsten grains are synthesized during the atomic mutual diffusion process.

2.3 Microhardness

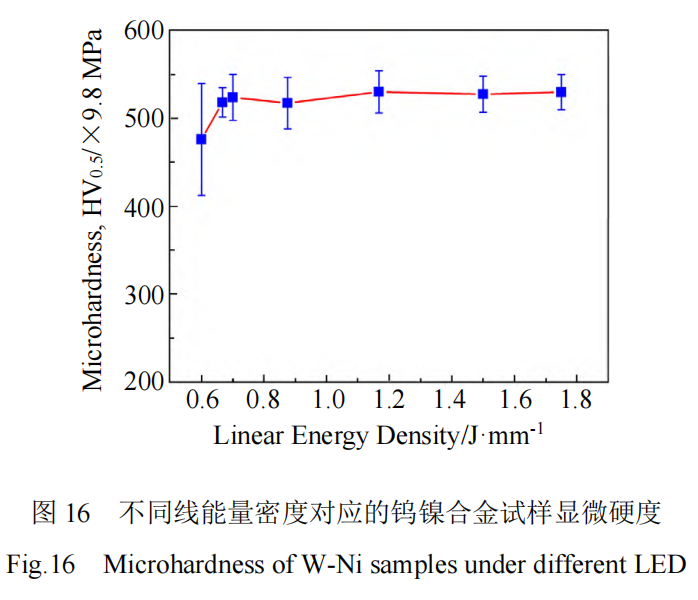

Figure 16 shows the microhardness of tungsten-nickel alloy samples formed by laser powder bed melting at different linear energy densities. It can be seen from the figure that with the increase of linear energy density, the microhardness (HV0.5) of the tungsten-nickel sample generally increases first and then tends to stabilize, increasing from 4662.6 MPa to 5192.3 MPa. At low linear energy density, the microhardness is affected by the more irregular pore defects in the tungsten-nickel alloy sample and decreases to a certain extent. However, with the increase of the relative density of the tungsten-nickel alloy sample, its microhardness is basically not affected by the linear energy density.

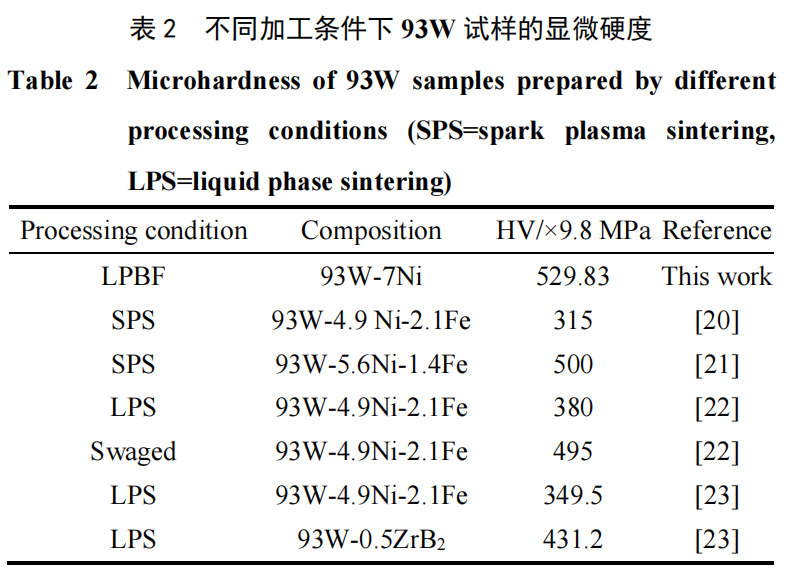

In addition, the microhardness of the 93W sample prepared by LPBF was compared with that of the samples prepared by spark plasma sintering, forging and liquid phase sintering, as shown in Table 2. By comparison, it can be found that the tungsten-nickel sample prepared by LPBF has higher microhardness. This is because although the forming mechanism of the tungsten-nickel alloy material prepared by LPBF is still liquid phase sintering, the edges of the tungsten particles are melted due to the direct effect of the high-energy laser beam. Since the forming process has obvious "sudden heating-sudden cooling" characteristics, its cooling rate is usually 103~105 K/s, which is much higher than the traditional powder metallurgy process, resulting in the generation of a large number of fine tungsten dendrites, making the tungsten-nickel alloy sample prepared by laser powder bed melting show higher microhardness.

In addition, the microhardness of the 93W sample prepared by LPBF was compared with that of the samples prepared by spark plasma sintering, forging and liquid phase sintering, as shown in Table 2. By comparison, it can be found that the tungsten-nickel sample prepared by LPBF has higher microhardness. This is because although the forming mechanism of the tungsten-nickel alloy material prepared by LPBF is still liquid phase sintering, the edges of the tungsten particles are melted due to the direct effect of the high-energy laser beam. Since the forming process has obvious "sudden heating-sudden cooling" characteristics, its cooling rate is usually 103~105 K/s, which is much higher than the traditional powder metallurgy process, resulting in the generation of a large number of fine tungsten dendrites, making the tungsten-nickel alloy sample prepared by laser powder bed melting show higher microhardness.

3 Conclusions

1) Laser powder bed melting additive manufacturing technology was used to prepare tungsten-nickel alloy with high tungsten content, and the optimized process parameter range was obtained. Higher linear energy density can promote liquid phase flow and tungsten particle rearrangement, accelerating the densification process; the relative density of the tungsten-nickel alloy sample prepared at a linear energy density of 1.5 J/mm was as high as 98.04%.

2) The forming mechanism of laser powder bed melting of tungsten-nickel alloy with high tungsten content is similar to that of powder sintering. Its microstructure is mainly characterized by liquid phase encapsulating W single phase formed by melting of low melting point Ni; at the same time, it also includes fine tungsten dendrites formed by melting and solidification of tungsten particle edges.

3) The tungsten-nickel alloy prepared by laser powder bed melting exhibits high microhardness, with the highest microhardness V0.5 being 5192.3 MPa; at the same time, when the irregular pores of the tungsten-nickel alloy sample are small, the microhardness is basically not affected by the linear energy density.

Paper citation information

Volume 52, Issue 8 Rare Metal Materials and Engineering Vol.52, No.8

W-Ni-Fe alloy is a tungsten-based heavy alloy, a powder metallurgy material, made of tungsten (W), nickel (Ni), and iron (Fe) through a specific process. It combines the high density and high strength of tungsten with the toughness of the nickel-iron binder phase, and is an important structural material in the industrial field.

The spherical W-Ni-Fe alloy powder produced by Stardust Technology is prepared by radio frequency plasma spheroidization process, with high purity and low oxygen, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flowability, high bulk density and high tap density.

For more details, please contact Vicky at 13318326185