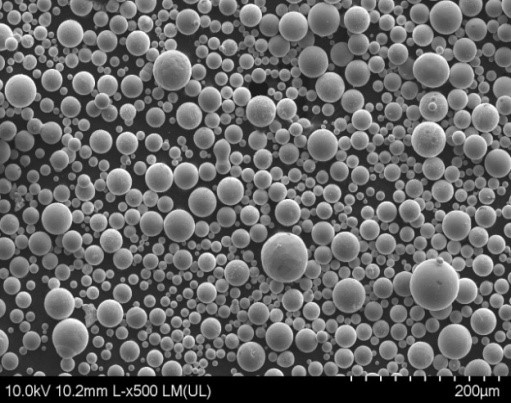

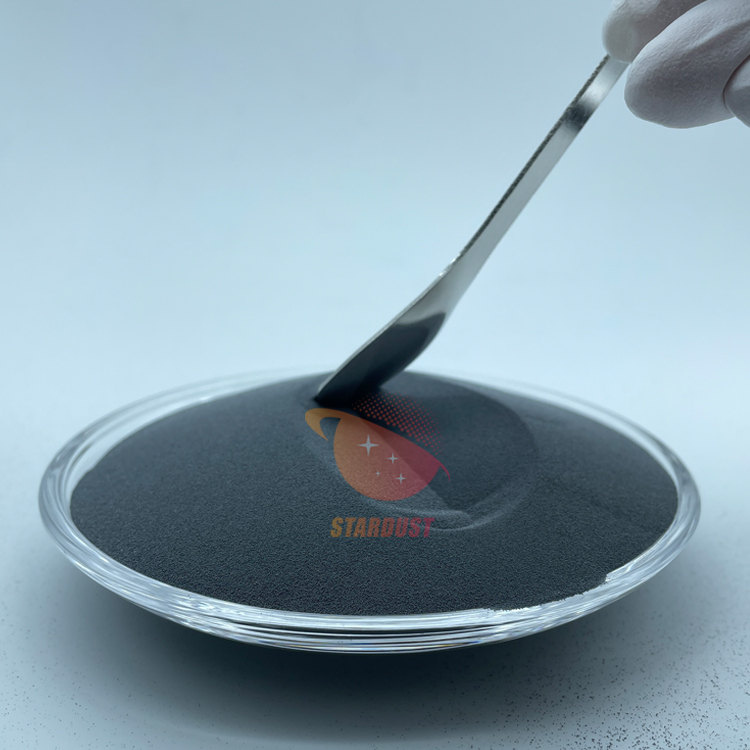

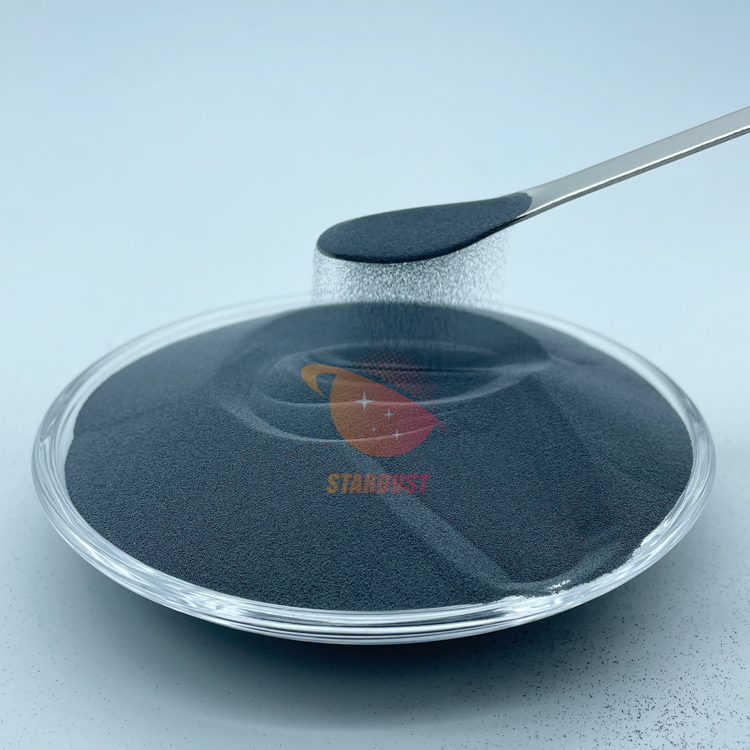

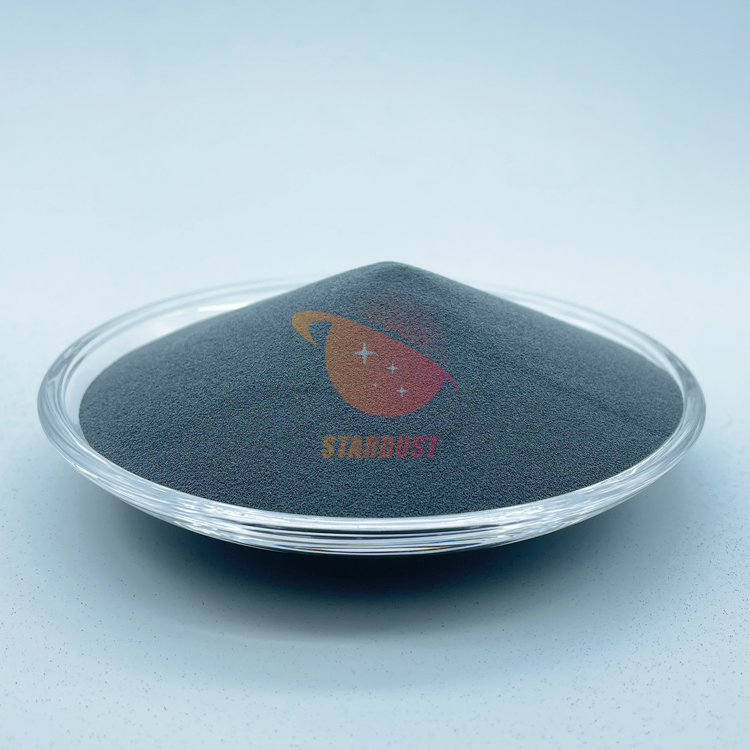

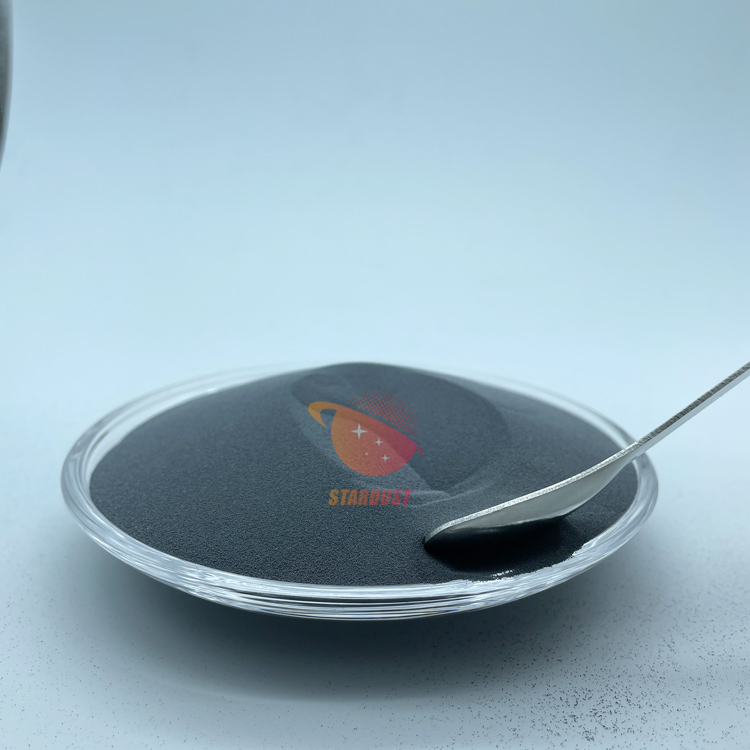

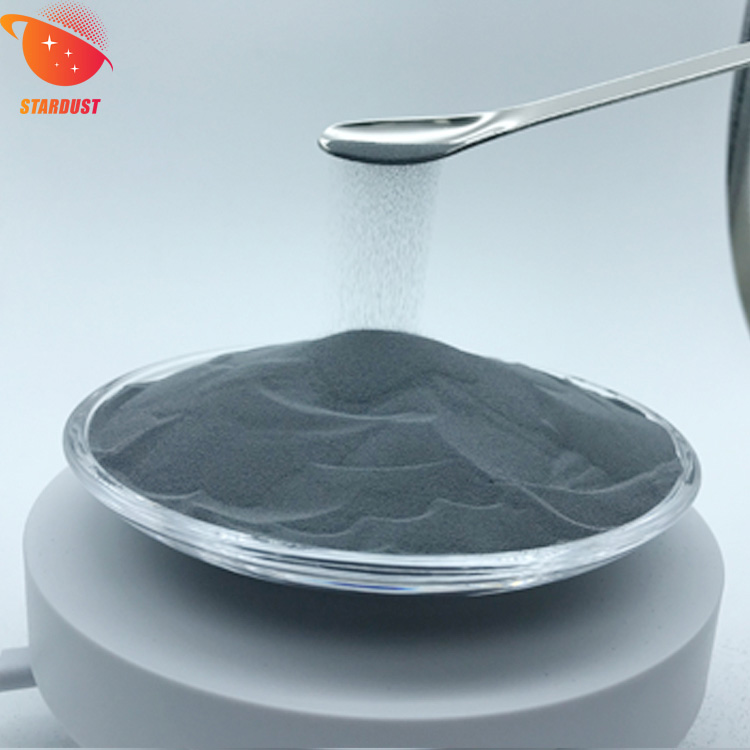

Spherical Refractory Ni-Ti Alloy Powder is made by Radio Frequency Plasma Spheroidization atomized method, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density.

Order(MOQ) :

1 KgPayment :

T/T ; L/C at sightProduct Origin :

ChinaShipping Port :

Foshan / Guangzhou / ShenzhenLead Time :

1-7 daysStardust company provide spherical refractory Ni-Ti alloy powder with high purity, low oxygen, high sphericity , smooth surface, no satellite spheres, uniform particle size distribution. As the lightest refractory metal, niobium has the characteristics of high melting point, high temperature strength and high specific strength, and no radioactivity. It's the perfect thermal protection material and structural material for aerospace engines. Spherical niobium powder is suitable for laser/electron beam additive manufacturing, hot isostatic pressing, laser cladding, hot/cold coating and other processes.

We can not only provide relatively mature research on spherical refractory Ni-Ti alloy Powder but also provide 3D printing services, metal spheroidization services, 3D printing machines and devices .

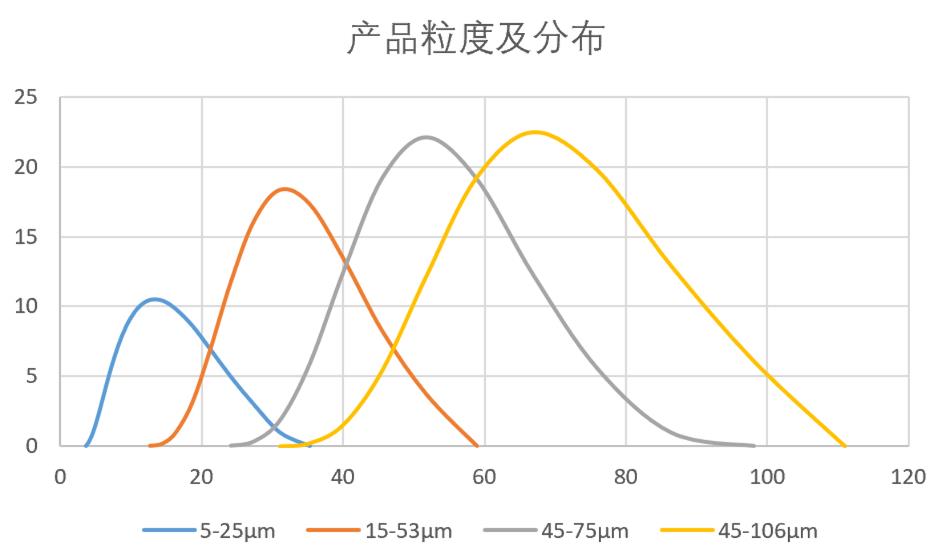

5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm.

(Various granularities can be customized according to customer requirements)

High purity (≥99.9%), low oxygen (≤300ppm), high sphericity (≥98%), smooth surface, no satellite spheres, uniform particle size distribution, and excellent flow properties (≤15.0s/50g), And high apparent density (≥4.5g/cm3) and tap density (≥5.5g/cm3).

Vacuum packaging, 1kg/bag, 2kg/bag; iron drum lined with plastic bag 25 kg/drum; special packaging is available according to user requirements.

| Chemical Composition | |||||

| Element | Value (%) | Test Method | Element | Value (%) | Test Method |

| Ti | remaining | — | Ni | 56 | ICP-AES |

| C | 0.0066 | ICP-AES | Fe | 0.008 | ICP-AES |

| N | 0.0071 | ICP-AES | O | 0.062 | ICP-AES |

| Density (g/cm3) | Hall Flow Rate (s/50g) | |||

| Apparent Density | Tap Density | Test Standard | Value | Test Standard |

| 3.57 | 4.26 | GB/T 1479-1984 GB/T 5162-2006 |

23.0 | GB/T 1482-2010 |

Spherical tungsten powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical tungsten powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical tungsten powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical tungsten powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical tungsten powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical tungsten powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Crystalline tungsten powder is a tungsten powder material with a special microstructure. It is composed of many small and regular tungsten crystal particles, which are connected to each other to form a unique crystal form. It has the characteristics of high purity, uniform particle size, and large specific surface area. It has important applications in many fields such as aerospace, electronics, and mechanical manufacturing. For example, it can be used to manufacture high-performance tungsten alloy parts and electronic emission devices, which can effectively improve the performance and quality of related products.

Read More

Spherical W-25Re powder is prepared by radio frequency plasma spheroidization technology, with high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

IPv6 network supported

IPv6 network supported